High-flux high-dirt-holding-capacity filtering element and preparation method thereof

A high-flux, filter element technology, applied in the field of high-dirt-holding pleated filter elements, can solve the problems of high filtration pressure difference, narrow flow channels, and high fluid resistance, and achieve a small filtration pressure difference, smooth water flow, and reduced fluid resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

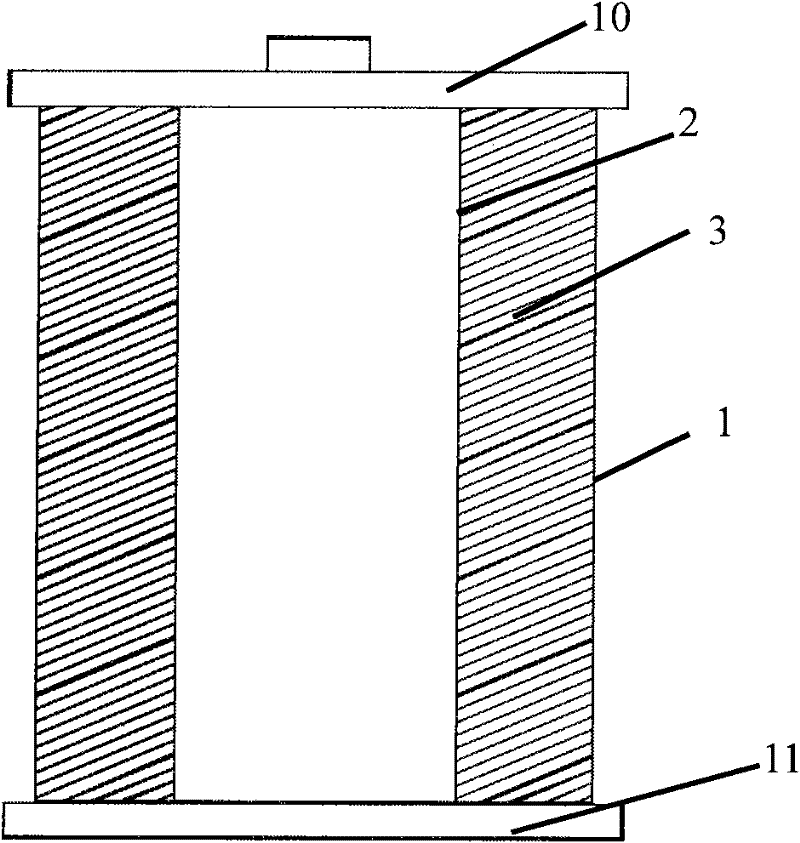

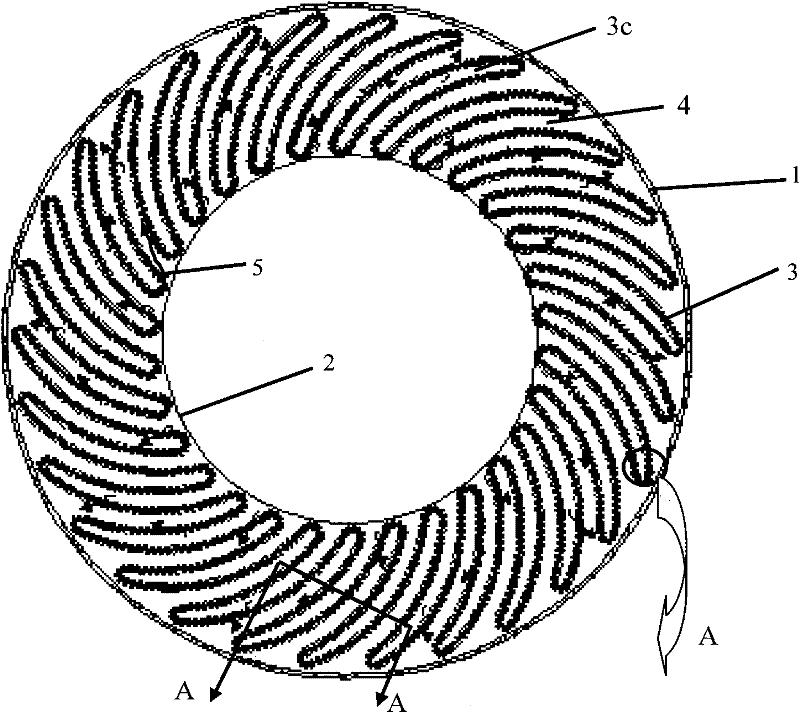

[0091] Embodiment 1 prepares 6 " large flux high dirt-holding capacity pleated filter element

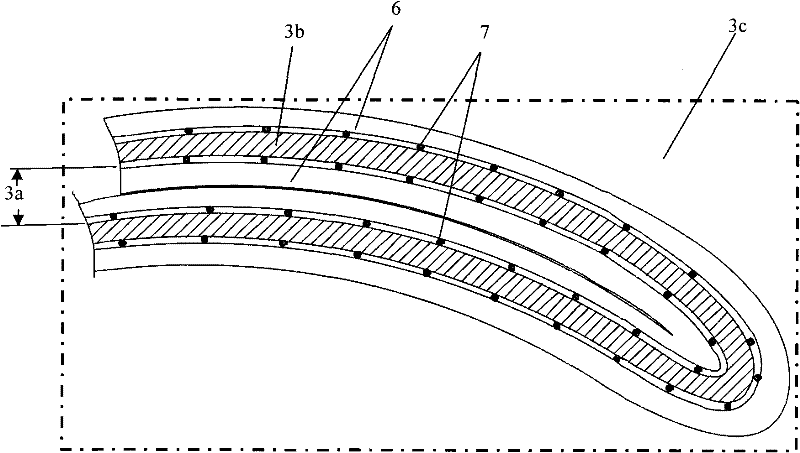

[0092] 1. Preparation of filter layer

[0093] The 4 layers of polypropylene filter materials with different thickness and filtration accuracy are arranged according to the direction of water flow during filtration, and the polypropylene materials are arranged in the order of filtration accuracy from low to high, and paved into a flat filter membrane (ie, filter layer 3b). Among them, the filtration precision of the filter material 3d is 100 μm, 50 μm, 20 μm, 1 μm; the thickness is 0.2mm, 0.2mm, 0.36mm, 0.5mm; the total thickness of the filter layer 3b is 1.26mm, and the filtration precision of the filter layer 3b is 1 μm , with a total filter area of 5.8m 2 .

[0094] 2. Preparation of plastic mesh layer

[0095] Arrange the polypropylene wire with a diameter of 0.9mm, that is, the first plastic wire 6, and the polypropylene wire with a diameter of 0.3mm, that is, the second p...

Embodiment 2

[0102] In addition to the use of 4 layers of polyethylene filter membrane materials in the step of preparing the filter layer, the filtration accuracy of the filter material layer is 100 μm, 50 μm, 20 μm, 5 μm; the thickness is 0.1mm, 0.16mm, 0.2mm, 0.2mm; the filtration accuracy is 5 μ m; Select polyethylene wire plastic wire for use in the plastic mesh layer step, wherein the diameter of the first plastic wire 6 is 1.5mm, and the vertical distance between two adjacent first plastic wires is 10mm; the second plastic wire 7 The diameter is 0.5mm, and the vertical distance between two adjacent second plastic filaments is 5mm; the intersection angle between the first plastic filament and the second plastic filament is 60°; the folded pleats of the arc-shaped structure in step 3 The arc of Except that the thickness of the water flow channel 4 is 4.0 mm, the rest is the same as that of the embodiment 1.

Embodiment 3

[0104] 1. Preparation of filter layer

[0105] Five layers of polytetrafluoroethylene membrane materials with different thickness and filtration precision are arranged according to the direction of water flow during filtration, and the polytetrafluoroethylene materials are arranged in the order of filtration precision from low to high, and paved into a plate filter membrane (that is, the filter layer 3b), wherein the filtration accuracy of the filter material layer is 100 μm, 80 μm, 50 μm, 20 μm, 5 μm; the thickness is 0.1mm, 0.1mm, 0.16mm, 0.2mm, 0.2mm; the total thickness of the filter layer is 0.76mm, and the filter The precision is 5μm, and the total filter area is 5.8m 2 .

[0106] 2. Preparation of plastic mesh layer

[0107] Arrange the polypropylene wire with a diameter of 0.9mm, that is, the first plastic wire 6, and the polypropylene wire with a diameter of 0.3mm, that is, the second plastic wire 7 at an acute angle of 45°, and bond and fix it after hot-melting to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com