Sponge ceramic catalyst as well as preparation method and application thereof in tap water treatment

A technology of ceramic catalyst and tap water, which is applied in the direction of catalyst activation/preparation, oxidized water/sewage treatment, water/sewage treatment, etc. It can solve the problems of difficult separation of impurities, unsatisfactory stability and mechanical strength, and low specific surface area. The effect of high sintering degree, high stability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

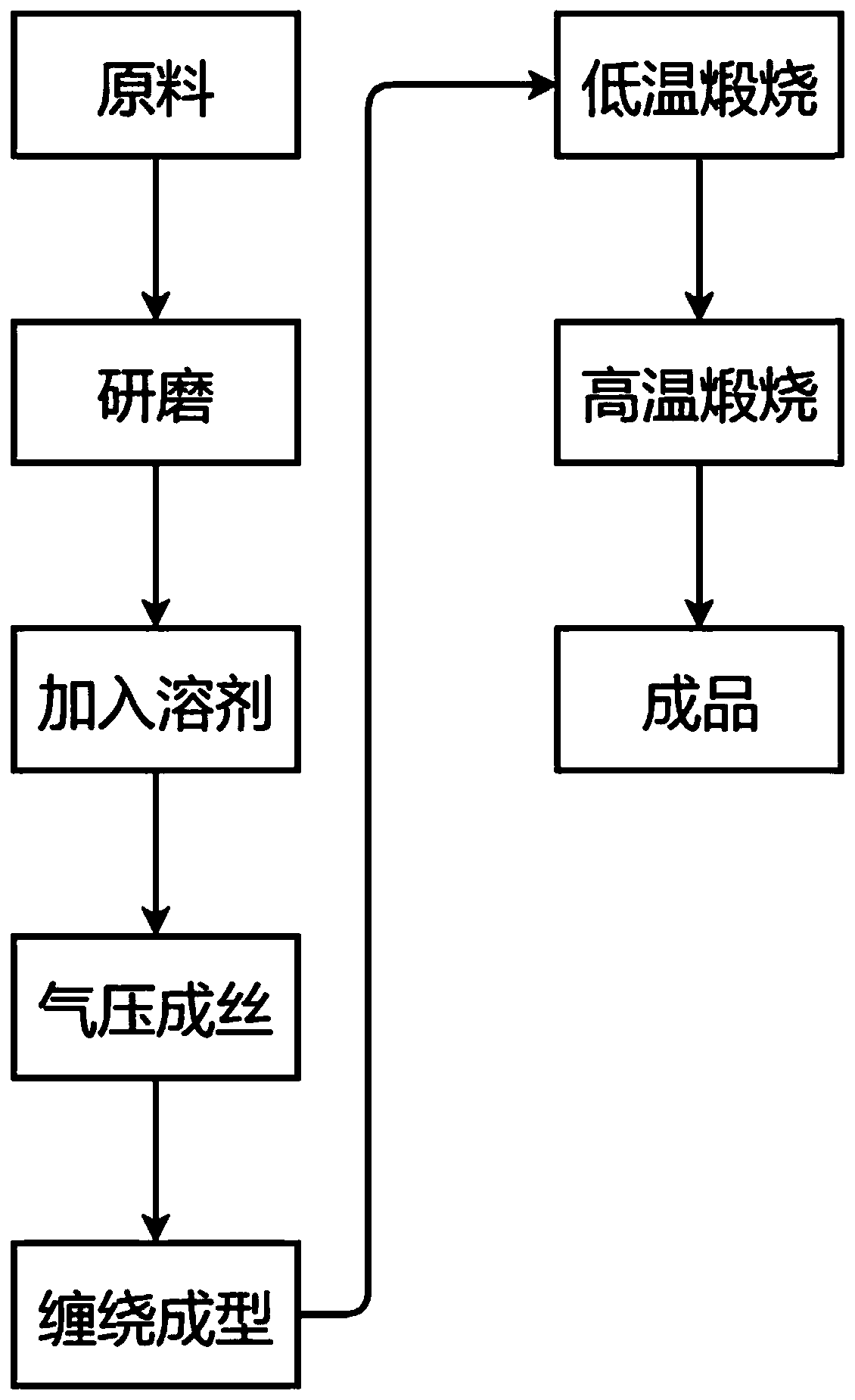

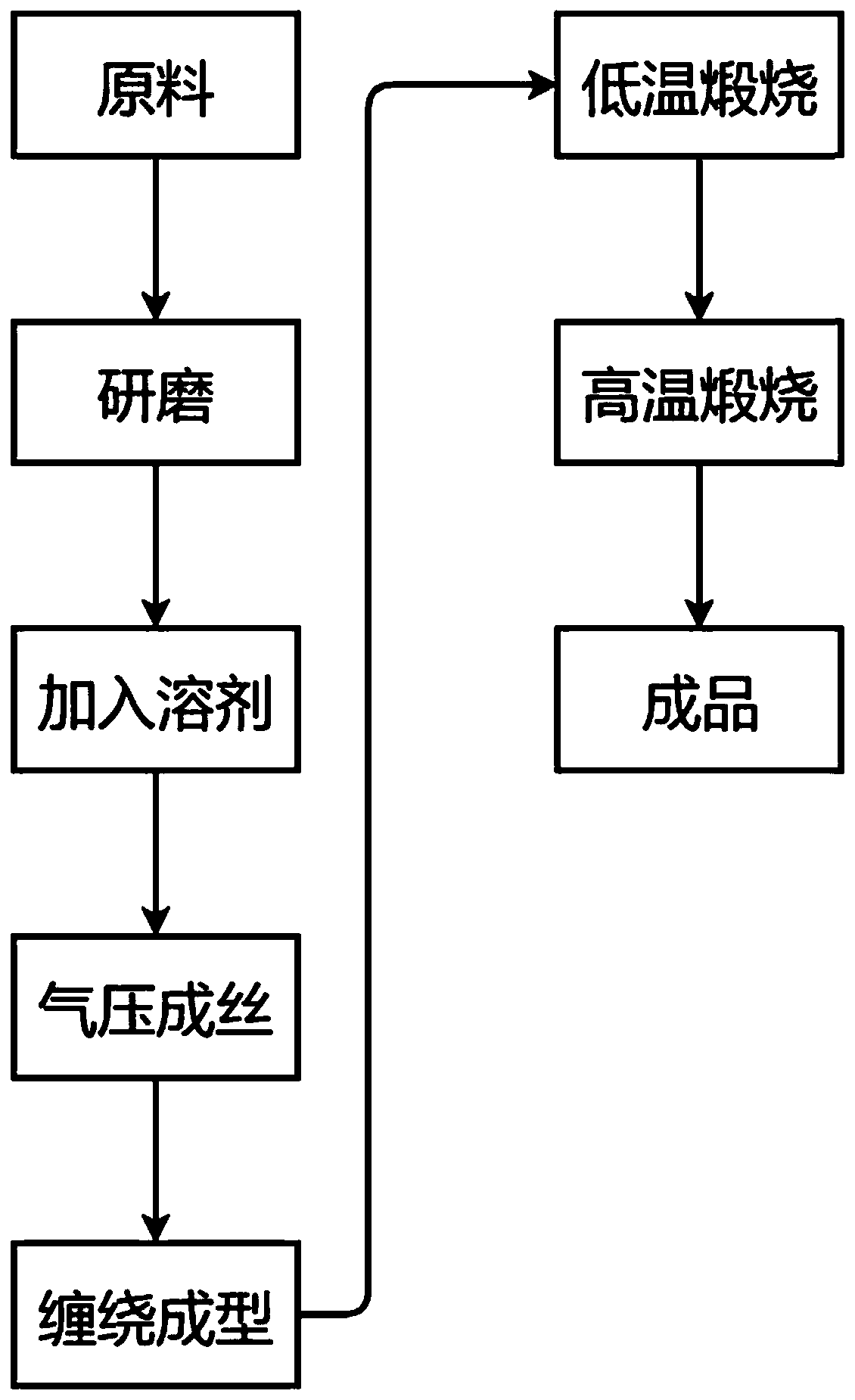

[0033] The process flow of the preparation method of the sponge ceramic catalyst of following embodiment is all as figure 1 shown, including steps:

[0034] (1) Grind and mix the raw materials evenly;

[0035] (2) adding solvent water to the raw material after grinding to form a colloid;

[0036] (3) colloidal air pressure into filaments to obtain filaments;

[0037] (4) winding and molding the filament to obtain a molded body;

[0038] (5) The formed body is calcined at low temperature to obtain the primary formed body;

[0039] (6) The primary molded body is calcined at high temperature to obtain a sponge ceramic catalyst.

Embodiment 1

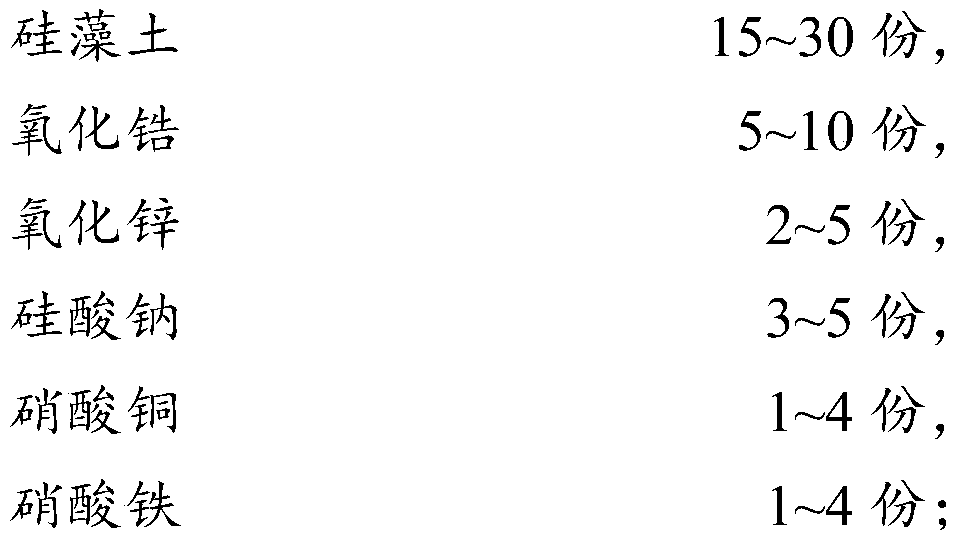

[0041] (1) Raw materials: diatomite, zirconia, zinc oxide, sodium silicate, copper nitrate, iron nitrate, cerium nitrate, and platinum nitrate in a mass ratio of 15:6:3:3:2:1:1:1.

[0042] (2) Raw material pretreatment: mix the raw materials and put them into a ball mill to grind until they can pass through a 300-mesh sieve, and mix thoroughly to obtain a powder. Add water to the powder, the volume ratio is 1:4, mix well to form a colloid.

[0043] (3) Pneumatic molding: use a high-pressure molding machine to control the pressure at 300 MPa, extrude the colloid into filaments to obtain filaments, and wrap the filaments in a winding molding machine to form them.

[0044](4) Calcination stage: low-temperature calcination: put the winding molded body into the muffle furnace, and raise the temperature to 500°C at a rate of 5°C / min, keep it for 2h, and calcinate to remove the moisture mixed into the powder to obtain the primary Molded body; high-temperature calcination: raise the ...

Embodiment 2

[0047] (1) Raw material preparation: Diatomaceous earth, zirconia, zinc oxide, sodium silicate, copper nitrate, iron nitrate, cerium nitrate, platinum nitrate according to the mass ratio of 21:8:2:3:2:1:1:1 .

[0048] (2) Raw material pretreatment: mix the raw materials and put them into a ball mill to grind until they can pass through a 300-mesh sieve, and mix thoroughly to obtain a powder. Add water to the powder, the volume ratio is 1:4, mix well to form a colloid.

[0049] (3) Pneumatic molding: use a high-pressure molding machine to control the pressure at 500 MPa, extrude the colloid into filaments to obtain filaments, and wrap the filaments in a winding molding machine to form them.

[0050] (4) Calcination stage: low-temperature calcination: put the winding molded body into the muffle furnace, and raise the temperature to 500°C at a rate of 5°C / min, keep it for 2h, and calcinate to remove the moisture mixed into the powder to obtain the primary Formed body. High-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com