Treatment device and treatment method for sewage

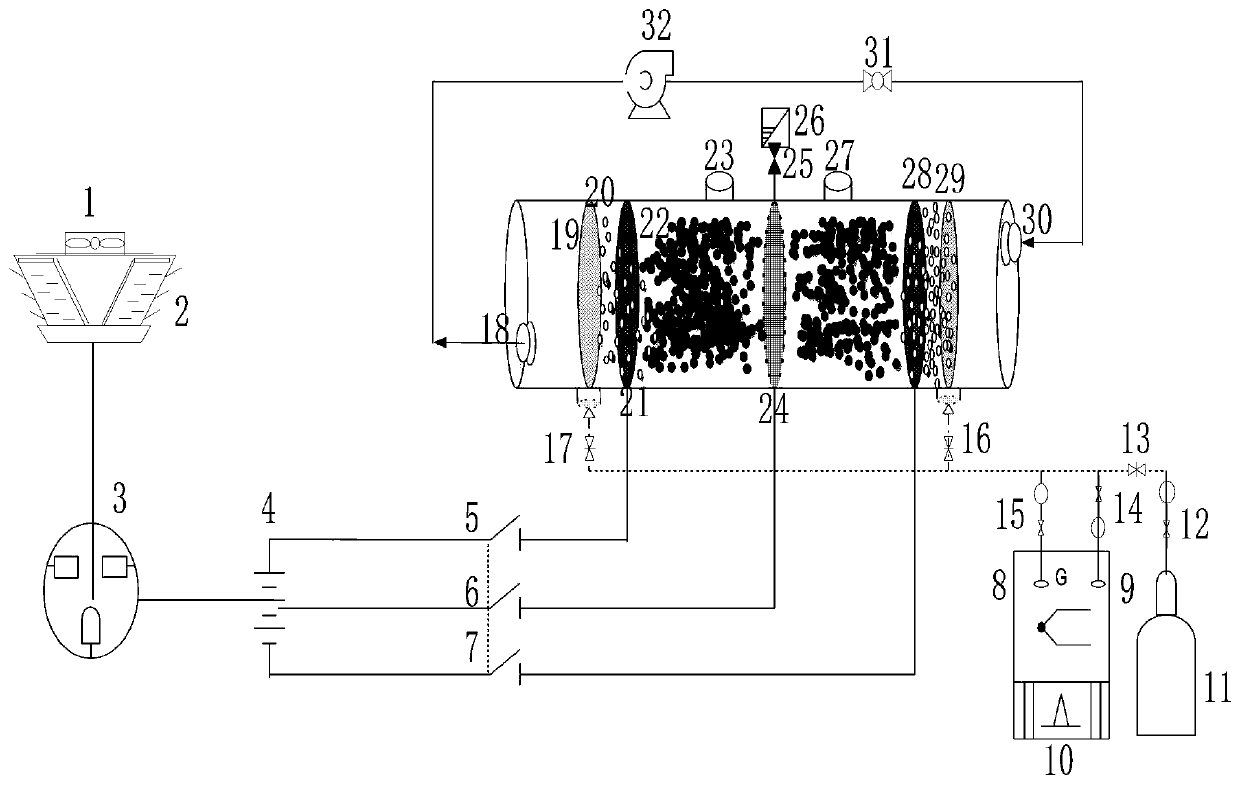

A sewage treatment device and sewage technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of ineffective control and treatment, incomplete removal of emerging pollutants, water Solve problems such as numerous technical steps, achieve the effects of excellent cycle treatment efficiency, small footprint, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

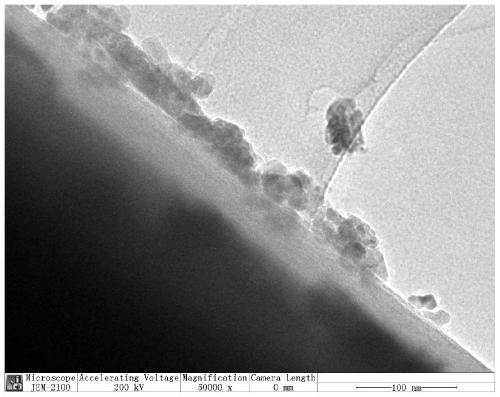

[0058] 1) Preparation of Mxene material: immerse the MAX phase material in HF aqueous solution, dry, wash and centrifuge, remove surface residue impurities, and dry until reaching a constant quality to obtain the Mxene material;

[0059] 2) Ferrite-modified MXene material: add the MXene material obtained in step 1) to the ferrite, ultrasonicate, filter and wash until neutral; then roast, and cool to obtain the ferrite-modified MXene material for use;

[0060] 3) Preparation of layered gas diffusion electrode: after ultrasonication of the ferrite-modified MXene material obtained in step 2), a mixture of a promoter, a pore-forming agent, a binder and anhydrous ethanol, stir in a constant temperature water bath until the mixture becomes a paste shape, take out the paste gel, put it on the axial press and press it repeatedly to form a sheet, wrap the sheet material on the nickel foam and continue the axial pressing until it does not contain water, and then roll it with a roller mac...

Embodiment 1

[0096] Electrochemical Cathode Example 1: Layered Gas Diffusion Electrode of Ferrite Modified Mxene

[0097] 1) Preparation of MXene material: Weigh 3.0g Ti 3 AlC 2 Materials and Measure 150mL of hydrofluoric acid solution into a round-bottomed flask. After 1h of ultrasonic treatment, react in a constant temperature reactor at 40°C for 72h. After the solution is cooled, wash with ultrapure water and centrifuge several times. Remove surface residue impurities until the pH of the washing liquid is not lower than 6, and then fully dry in a vacuum oven at 60°C until a constant quality is obtained to obtain MXene materials.

[0098] 2) Ferrite modified MXene material: Accurately weigh 808mg Fe(NO 3 )3 9H 2 O solid and 125.84 mg MnCl 2 solid, adding Fe(NO 3 ) 3 9H 2 O solid and MnCl 2 Solid, stirred with a magnetic stirrer to make it evenly mixed and completely dissolved to obtain a mixed solution, in which Fe(NO 3 ) 3 0.02mol / L, MnCl 2 0.01mol / L, add 5mL of polyethylene ...

Embodiment 2

[0100] Electrochemical Cathode Example 2: Ferrite Modified Carbon Fiber Cloth Electrochemical Cathode

[0101] 1) Cut the original carbon fiber cloth into a circle with a diameter of 10 em, and soak the carbon cloth with a mixture of 10% nitric acid by mass fraction and 10% sulfuric acid solution by mass fraction (nitric acid: sulfuric acid volume ratio is 3:1) , after 30 minutes of ultrasonic treatment, react in a constant temperature reactor at 50°C for 24 hours. After the solution is cooled, wash it with ultrapure water several times to remove surface residue impurities until the pH of the washing solution is neutral, and then in 50°C Fully dry in a vacuum oven until a constant quality is obtained to obtain a modified carbon fiber cloth;

[0102] 2) Add 0.8mol / L Fe(NO 3 ) 3 9H 2 O and 0.4mol / L Cu(NO 3 ) 2 ·3H 2 O, sonicate for 1 hour to mix evenly and dissolve completely to obtain a mixed solution, add ammonium fluoride and urea to it and continue stirring, then add m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com