Preparation method of easy-digestion sugarcane byproduct feed

A by-product and easily digestible technology, which is applied in the field of sugarcane by-product feed preparation, can solve the problems of combined steam puffing and ammoniation treatment that have not been reported, and can improve the immunity of livestock and poultry, reduce the medicinal taste, and promote digestion and absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

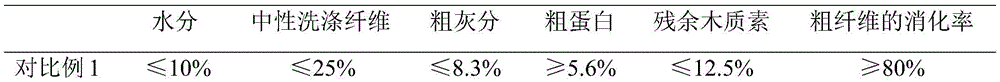

Examples

Embodiment 1

[0030] (1) Bagasse 100kg, expanded by continuous steam explosion, steam pressure 1.6MPa, expansion time 8min;

[0031] (2) Treat the expanded bagasse in 5% calcium oxide solution at 55° C. for 1.5 h, and then undergo ammonification treatment with 1.2% ethylenediamine solution at normal temperature;

[0032] (3) Centrifuge to obtain Precipitation A; Precipitation A, molasses and water are formed into a solid-state fermentation medium according to the ratio of 7:2:1;

[0033] (4) add 5kg saprophyte, trichoderma (ratio of saprophyte, trichoderma is 2:1) to ferment for 15 days in the solid-state fermentation medium that step (3) obtains;

[0034] (5) Weigh 16kg of kudzu root, 15kg of Panax notoginseng, 6kg of papaya, 4kg of glutinous rice vine, 11kg of Bupleurum radix, 0.5kg of licorice, 5kg of honeysuckle, 2kg of clove, and 12kg of burdock. In the mixture, mix evenly, concentrate, and dry, that is.

Embodiment 2

[0036] (1) Bagasse 100kg, expanded by continuous steam explosion, steam pressure 2.0MPa, expansion time 10min;

[0037] (2) Treat the expanded bagasse in 5% calcium oxide and 5% sodium hydroxide solution at 60° C. for 1.0 h, and then undergo ammoniation treatment with 0.5% ethylenediamine solution;

[0038] (3) Centrifuge to obtain Precipitation A; Precipitation A, molasses and water are formed into a solid-state fermentation medium according to the ratio of 10:3:1.2;

[0039] (4) Add 5 kg of Coriolus tomentosa, Pleurotus tricolor, Candida aquaticus, and Sphaeroides yeast mixed bacteria (ratio is 5:1:3:2) to the solid-state fermentation medium obtained in step (3) to ferment for 5 days ;

[0040] (5) Add traditional Chinese medicine components to the fermented product in step (4), mix uniformly, concentrate, and dry to obtain the product.

[0041] Among them, the traditional Chinese medicine components are prepared from the following traditional Chinese medicine raw material...

Embodiment 3

[0043] (1) Bagasse 100kg, expanded by continuous steam explosion, steam pressure 1.2MPa, expansion time 5min;

[0044] (2) Treat the expanded bagasse in 5% calcium oxide solution at 80°C for 2.5 hours, and then undergo ammonification treatment with 1.0% ethylenediamine solution at normal temperature;

[0045] (3) Centrifuge to obtain Precipitation A; Precipitation A, molasses and water are formed into a solid-state fermentation medium according to the ratio of 8:2.5:1.5;

[0046] (4) add 5kg white rot fungus, Trichoderma (ratio is 2:3) to ferment for 20 days in the solid-state fermentation medium that step (3) obtains;

[0047] (5) Add traditional Chinese medicine components to the fermented product in step (4), mix uniformly, concentrate, and dry to obtain the product.

[0048] Among them, the traditional Chinese medicine ingredients are prepared from the following traditional Chinese medicine raw materials in parts by weight: Pueraria 18kg, Panax notoginseng 20kg, Papaya 9k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com