A kind of alkaline iron oxide anti-corrosion coating and preparation method thereof

An anti-corrosion coating, iron oxide technology, applied in anti-corrosion coatings, coatings, fire-resistant coatings, etc., can solve problems such as poor corrosion resistance, and achieve the effects of excellent mechanical properties, easy processing and preparation, and cheap and readily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

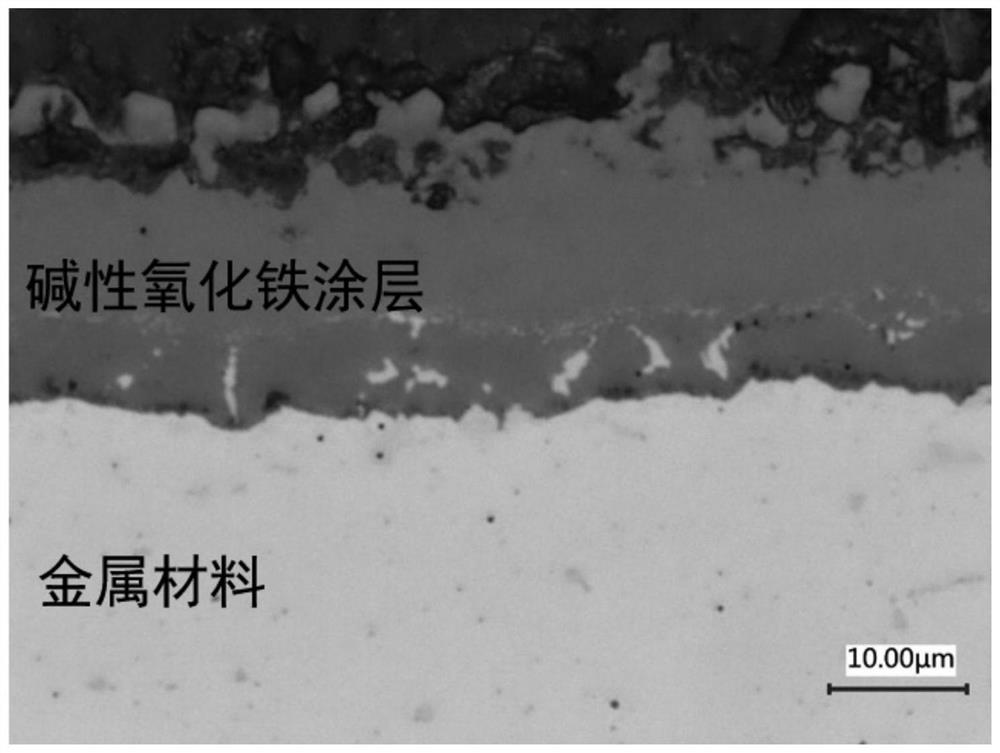

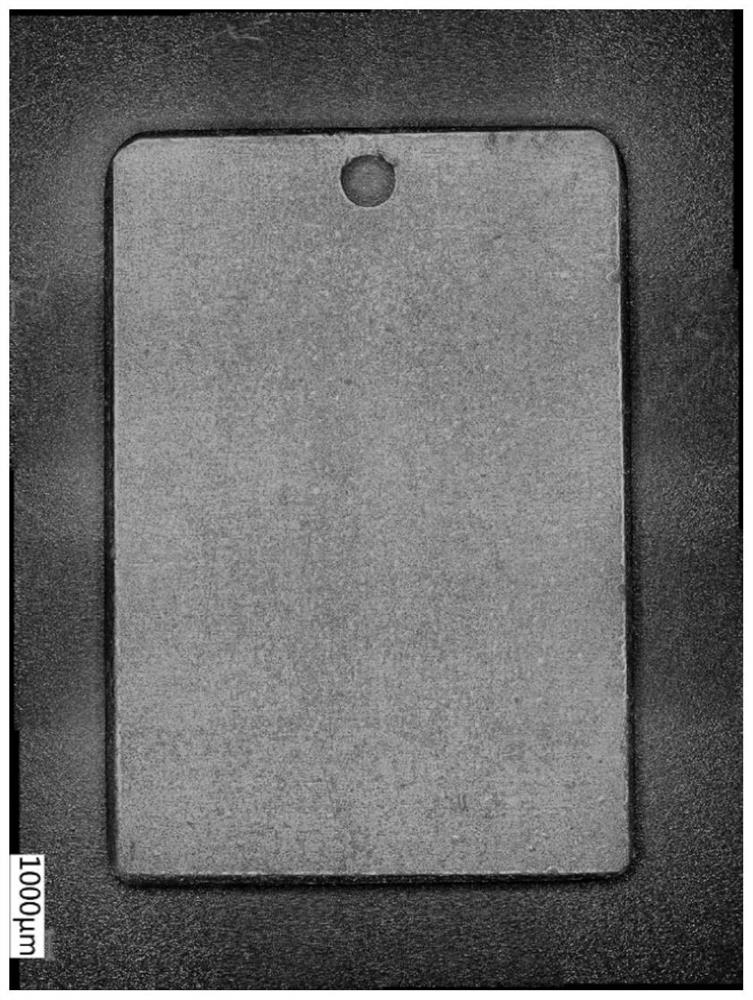

[0017] Using A3 steel plate as the application material (metal material substrate), a basic iron oxide layer with a thickness of 25 μm was prepared on its surface by plasma spraying method (wherein the mass ratio of lithium: iron: oxygen = 1.7:67.4:30.9). This is the basic iron oxide anti-corrosion coating with a single-layer structure, and its actual photo is as follows figure 1 shown.

[0018] The above-mentioned A3 steel plate prepared with a single-layer alkaline iron oxide anti-corrosion coating on the surface was used as the hull material of a fishing boat, soaked in seawater for 2 years, and the same batch of original A3 steel plates (without any anti-corrosion coating) were used as a control for the same seawater immersion experiments. It was found that the A3 steel plate with basic iron oxide anti-corrosion coating did not undergo obvious corrosion, and the anti-corrosion coating remained intact, while the surface of the original A3 steel plate was more severely corr...

Embodiment 2

[0020] 304 stainless steel plate is used as the application material, and Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (molar ratio Li 2 CO 3 :Na 2 CO 3 :K 2 CO 3 =43.5:31.5:25) The molten salt is used as the electrolyte, and the applied material is the anode nickel plate as the cathode, and an alkaline iron oxide layer (lithium: iron: oxygen) with a thickness of 10 μm has been prepared on its surface by means of electrochemical pre-oxidation. Mass ratio=7.3:58.9:33.8), this is the basic iron oxide anticorrosion coating of single-layer structure.

[0021] The 304 stainless steel plate prepared with a single-layer alkaline iron oxide anti-corrosion coating on the surface was used as the structural material of the offshore drilling platform, and was exposed in the ocean air for 3 years. It was found that the 304 stainless steel plate with the basic iron oxide anti-corrosion coating did not undergo obvious corrosion, and the anti-corrosion coating remained intact. This shows that t...

Embodiment 3

[0023] Using ductile iron pipe as the application material, a basic iron oxide layer with a thickness of 20 μm was prepared on the surface by chemical vapor deposition (mass ratio of lithium: iron: oxygen = 1.7:67.4:30.9), which is a single layer Structural alkaline iron oxide anti-corrosion coating.

[0024] The above-mentioned nodular cast iron pipes prepared with a single-layer alkaline iron oxide anti-corrosion coating on the surface were used as water pipelines and buried one meter underground in typical soil in Wuhan for 4 years. It was found that no obvious corrosion occurred in the ductile iron pipe. This result indicates that the basic iron oxide anticorrosion coating has excellent corrosion protection ability for iron-based materials in soil environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com