Preparation method and application of low-volume-change metal secondary battery negative electrode

A solid electrolyte and metal-organic framework technology, applied in the field of electrochemical energy storage, can solve the problems of SEI film stability, dendrite growth, electrode volume change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

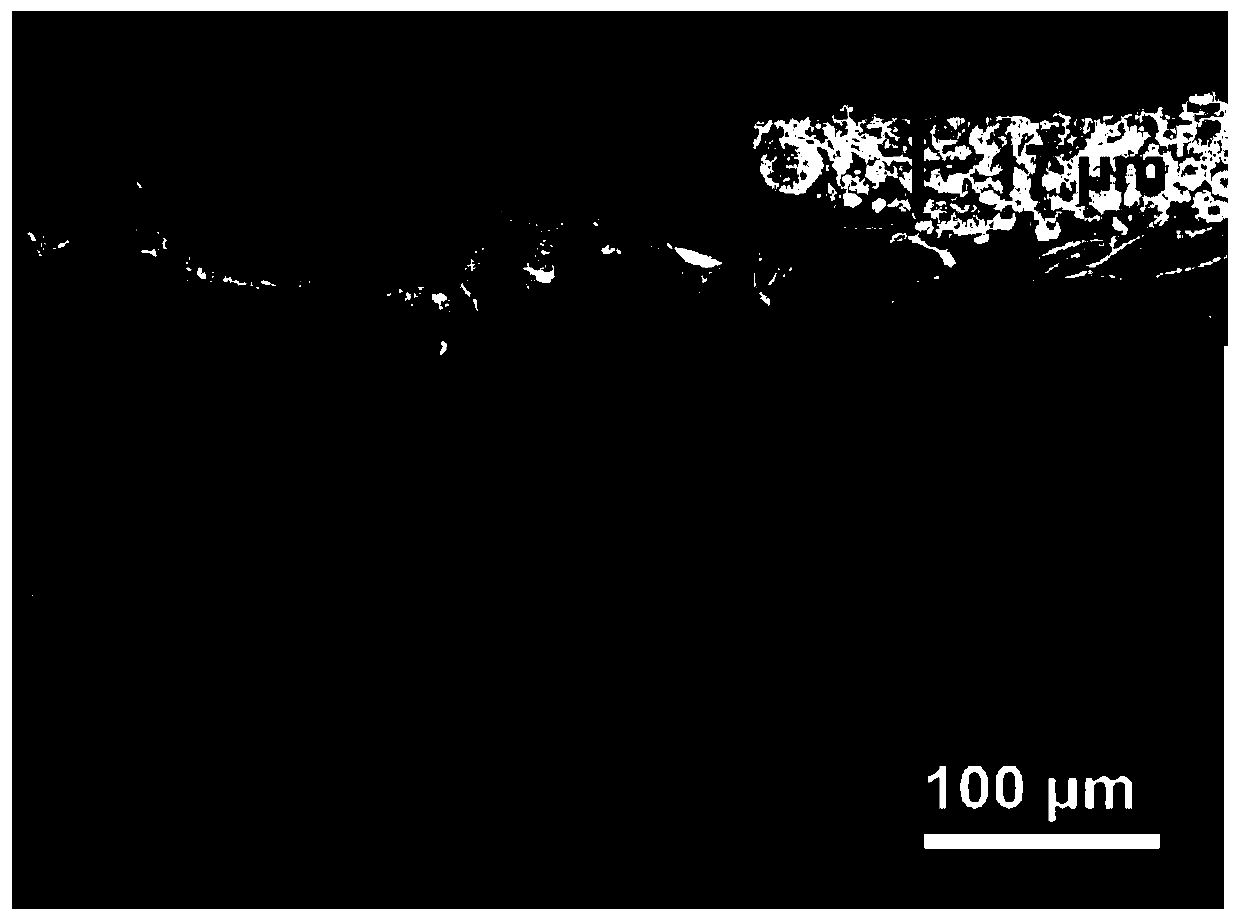

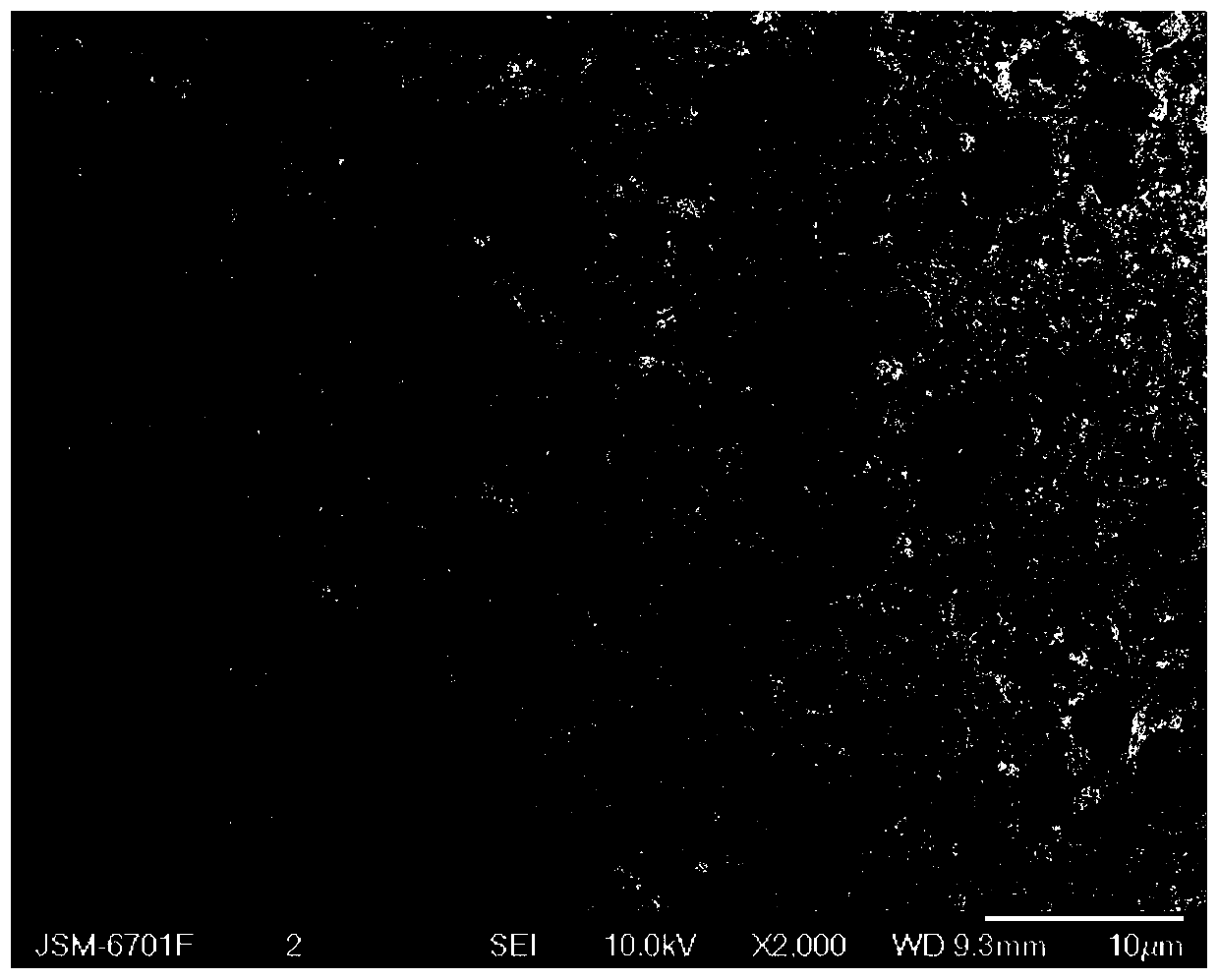

[0046] (1) Preparation of spun membrane composite three-dimensional porous current collector: First, under the protection of argon atmosphere, commercialized cotton is placed in a carbonization furnace, and the three-dimensional carbon fiber obtained by carbonization at a high temperature of 1200°C for 4 hours. Secondly, the MOF-808 powder and PVDF are uniformly mixed in a ratio of 3:1 to prepare a slurry for use. Next, spread the three-dimensional carbon fiber obtained by carbonization of cotton on a clean copper foil, inject the prepared slurry into a 10mL syringe, set the operating voltage to 10kV, the receiving distance between the needle tip and the three-dimensional carbon fiber is 10cm, and the injection flow rate It is 0.5 mL / h; the membrane is formed by electrospinning technology, and then vacuum dried at 80° C. for 10 hours, and the spinning membrane composite three-dimensional porous current collector is formed after drying, which is taken out for battery testing. Th...

Embodiment 2

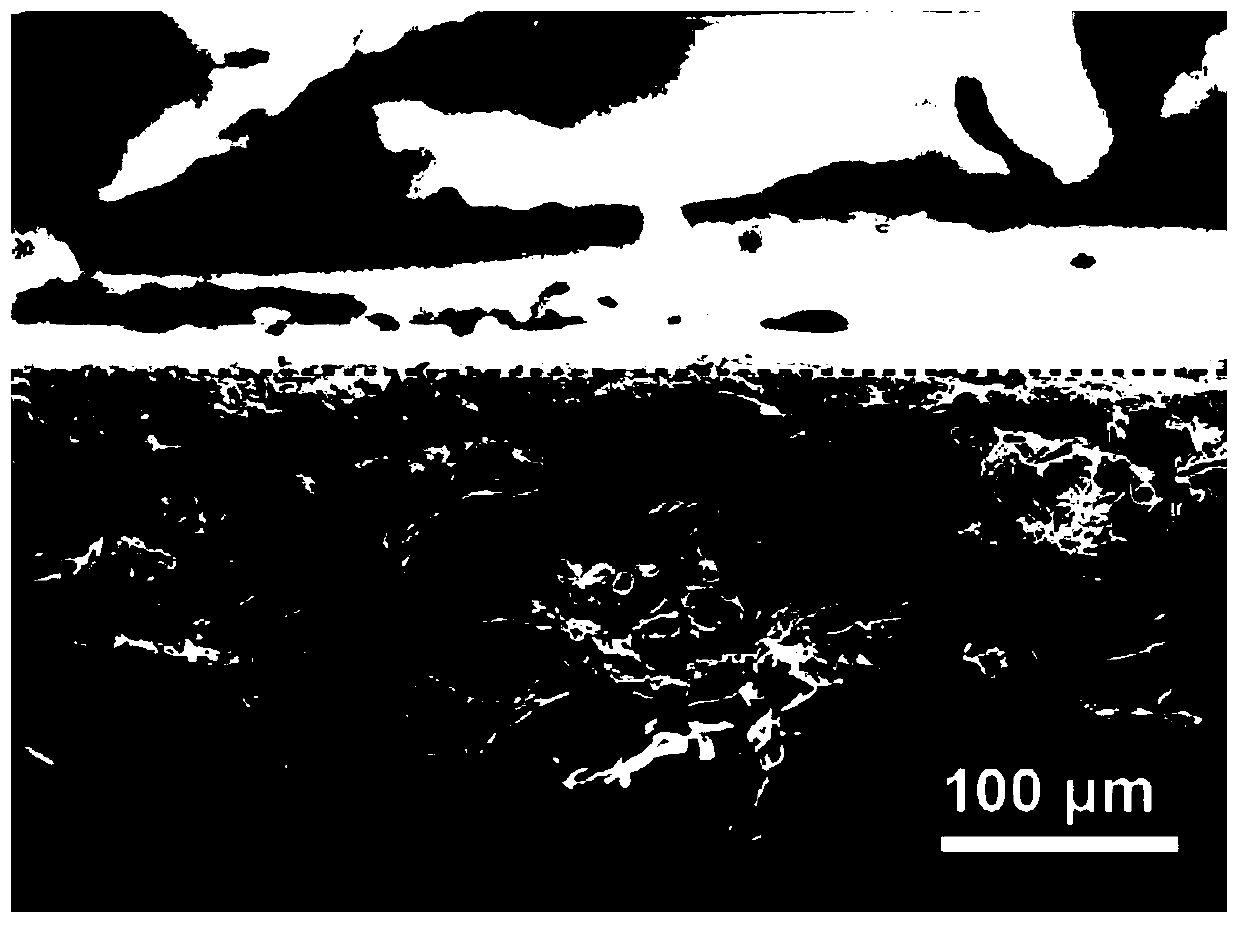

[0056] Other conditions are the same as in Example 1, except that (1) Lithium deposited by electrochemical method 15mAh cm -2 . Image 6 It is shown that metallic lithium is uniformly deposited in the three-dimensional porous carbon fiber without dendritic lithium dendrites on the surface. The thickness of the three-dimensional composite electrode after the deposition of metallic lithium is about 124μm, which is close to the electrode thickness before deposition, and the electrode volume change rate is only -1.6 %. The lithium negative electrode is at 1mA cm -2 It can circulate for 700 hours under current density. The reversible capacity of the assembled MOF-HCF@Li|LFP battery can reach 161mA h g -1 Circulate 200 times, the capacity retention rate is 91.8%, and the volume expansion rate is 2.1%.

Embodiment 3

[0058] The other conditions are the same as in Example 1, except for the high-temperature carbonization at 1000°C. The thickness of the spinning membrane is 15μm, and the pore volume per unit area is 0.002cm 3 / cm 2 , A spinning membrane with a pore size of 100-500 nm, and the total thickness of the spinning membrane composite three-dimensional porous current collector is about 111 μm. Lithium deposited by electrochemical method 6mA h cm -2 , The metal lithium is uniformly deposited in the three-dimensional porous carbon fiber, and there is no dendritic lithium dendrites on the surface. The thickness of the three-dimensional composite electrode after the deposition of metal lithium is about 115μm, which is close to the electrode thickness before the deposition, and the electrode volume change rate is only -3.6% . The lithium negative electrode is at 1mA cm -2 It can circulate for 800 hours under current density. The reversible capacity of the assembled MOF-HCF@Li|LFP battery c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com