Method for preparing hydrogen-sensitive sensing material based on platinum nano-cluster/silicon carbide nanosheet

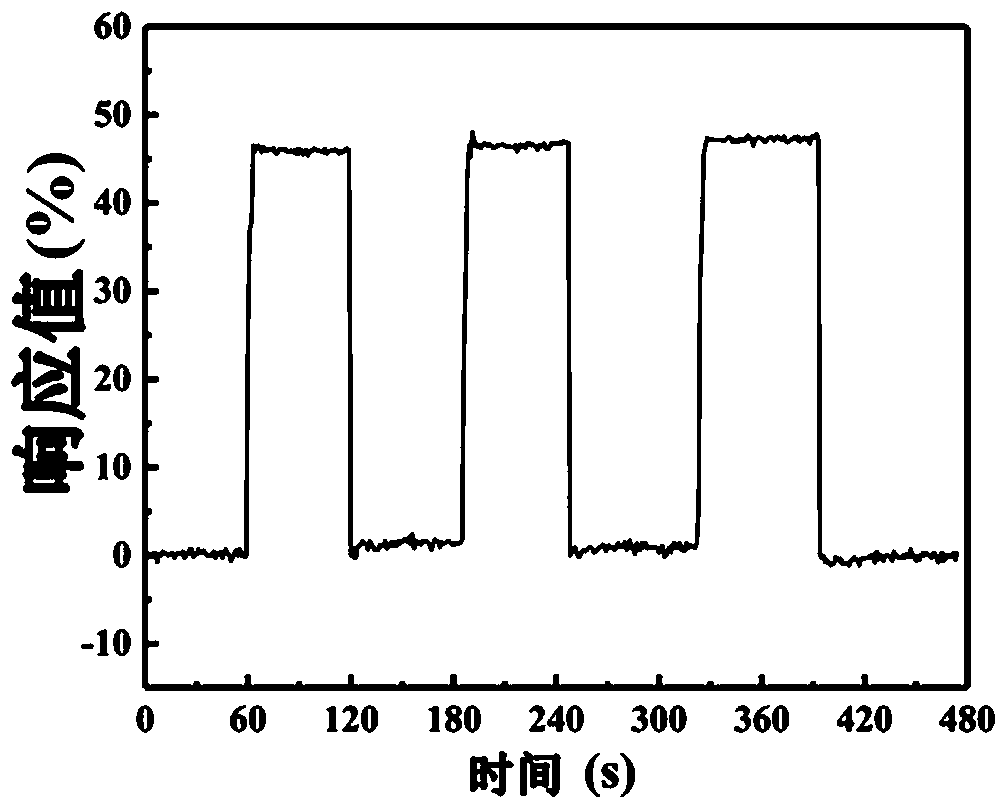

A sensing material and silicon carbide technology, which is applied in the field of preparation of hydrogen sensing materials, can solve the problems of long gas sensing response/recovery time, complex preparation method, baseline drift, etc., so as to improve the gas sensing performance and preparation method. The effect of simple, stable response values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0033] a) Prepare graphene oxide / silicon powder mixed solution: mix silicon powder and graphene oxide in 100 ml of deionized water at a mass ratio of 1:1, and pulverize at 40 kHz and 100 watts of ultrasonic power until the solution is uniform;

[0034] b) Freeze-drying: After freezing the above mixed solution with liquid nitrogen, transfer it to a freeze dryer for freeze-drying, and obtain a graphene oxide / silicon powder mixture after all the water is removed;

[0035] c) Carbothermal reduction: put the above-mentioned graphene oxide / silicon powder mixture in a corundum crucible, under the protection of an argon atmosphere with a flow rate of 0.1-1.0 L / min, raise the temperature to 1400 °C, keep it warm for 2.0 hours, and cool naturally to room temperature;

[0036] d) Cleaning and drying: soak the carbothermally reduced product in a concentrated nitric acid: hydrofluoric acid mixed acid solution with a volume ratio of 3:1 for 6.0 hours, then wash with deionized water and dry ...

reference example 2

[0038] a) Prepare graphene oxide / silicon powder mixed solution: mix silicon powder and graphene oxide in 100 ml of deionized water at a mass ratio of 3:1, pulverize at 40 kHz, 100 watts of ultrasonic power until the solution is uniform;

[0039] b) Freeze-drying: After freezing the above mixed solution with liquid nitrogen, transfer it to a freeze dryer for freeze-drying, and obtain a graphene oxide / silicon powder mixture after all the water is removed;

[0040] c) Carbothermal reduction: put the above-mentioned graphene oxide / silicon powder mixture in a corundum crucible, under the protection of an argon atmosphere with a flow rate of 0.1-1.0 L / min, raise the temperature to 1400 °C, keep it warm for 2.0 hours, and cool naturally to room temperature;

[0041] d) Cleaning and drying: soak the carbothermally reduced product in a concentrated nitric acid: hydrofluoric acid mixed acid solution with a volume ratio of 3:1 for 6.0 hours, then wash with deionized water and dry to obta...

reference example 3

[0043] a) Prepare graphene oxide / silicon powder mixed solution: mix silicon powder and graphene oxide in 100 ml of deionized water at a mass ratio of 3:1, pulverize at 40 kHz, 100 watts of ultrasonic power until the solution is uniform;

[0044] b) Freeze-drying: After freezing the above mixed solution with liquid nitrogen, transfer it to a freeze dryer for freeze-drying, and obtain a graphene oxide / silicon powder mixture after all the water is removed;

[0045] c) Carbothermal reduction: put the above-mentioned graphene oxide / silicon powder mixture in a corundum crucible, under the protection of an argon atmosphere with a flow rate of 0.1-1.0 liters / min, heat up to 1500 °C, keep it warm for 3.0 hours, and cool naturally to room temperature;

[0046] d) Cleaning and drying: soak the carbothermally reduced product in a concentrated nitric acid: hydrofluoric acid mixed acid solution with a volume ratio of 3:1 for 6.0 hours, then wash with deionized water and dry to obtain the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com