Waterproof breathable fabric and preparation method thereof

A breathable and fabric technology, applied in the field of textile fabrics, can solve the problems of stuffy heat, poor inner warmth and comfort, and reduce fabric air permeability, etc., and achieve the effects of increased breaking strength, excellent flame retardancy, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

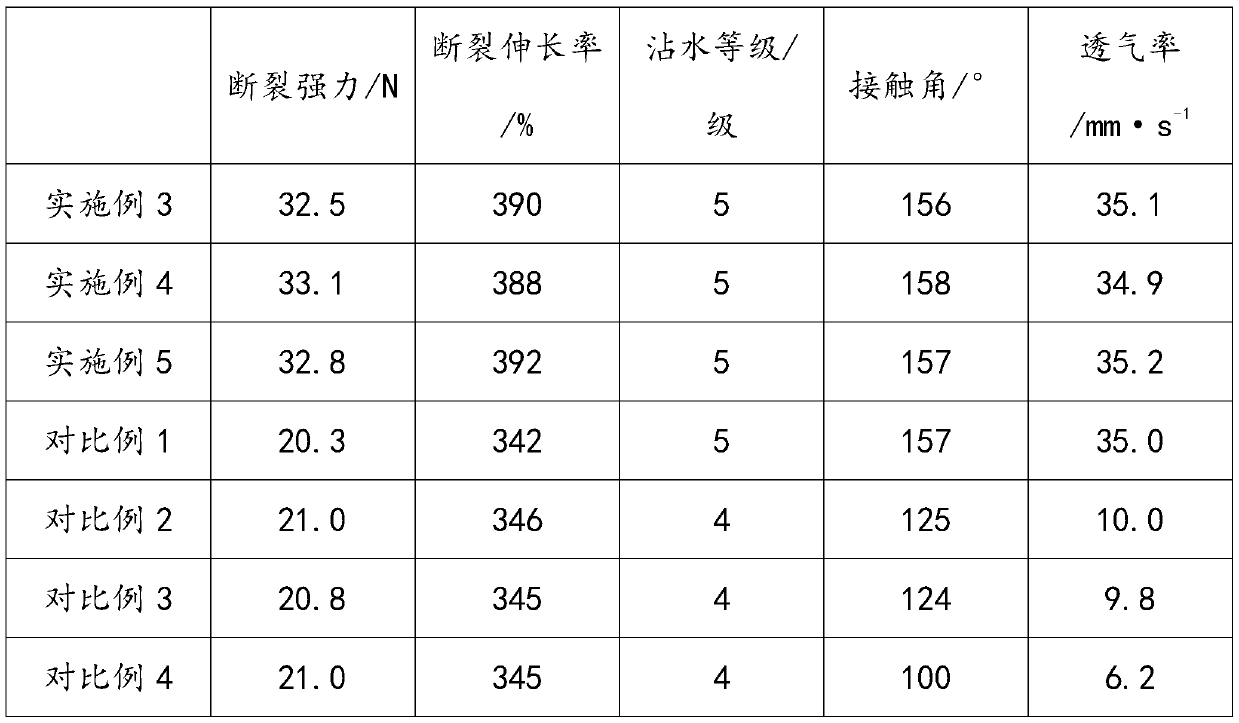

Examples

preparation example Construction

[0054] Preparation of modified nano silica:

[0055] (1) Add 6 mL of tetraethyl orthosilicate (TEOS) to 12 mL of absolute ethanol, then add 1.2 mL of HCl solution with a concentration of 2 mol / L dropwise, keep stirring the mixed solution in a water bath at 55°C for 4 hours, and cool After reaching room temperature, slowly add 0.5 mL of ammonia solution with a concentration of 2 mol / L, and stir at room temperature for 5 h;

[0056] (2) Add 0.6mL dimethyldiethoxysilane dropwise, react at a constant temperature of 55°C for 22h, wash the obtained product with toluene and absolute ethanol, centrifuge 3 times, and dry to obtain the modified Sexual nano silica;

[0057] Dimethyldiethoxysilane is grafted on the silica through the hydroxyl reaction on the surface of the silica. This organic segment increases the dispersion of nano-silica in the film matrix, which is conducive to the preparation of uniform Functional thin film coatings also improve the physical or chemical interaction...

Embodiment 1

[0059] Preparation of modified viscose fiber:

[0060] (1) Use 0.1mol / L HCl aqueous solution to adjust the pH value of the viscose spinning stock solution to 6-7, add phosphoric acid, stir at 100r / min for 20min, add sodium carboxymethylcellulose, and continue stirring until completely dissolved;

[0061] (2) Vacuum static defoaming for 24 hours to obtain a composite spinning solution, which is squeezed through a spinneret into a coagulation bath to solidify into filaments, stretched 1.5 times, washed with water, dried at 115°C and coiled Modified viscose fiber is obtained after winding; the composition of the coagulation bath is sulfuric acid 90g / L, sodium sulfate 300g / L, zinc sulfate 15g / L, the temperature of the coagulation bath is 65°C, and the bath length is 2m;

[0062] Wherein, the mass ratio of viscose spinning dope, sodium carboxymethyl cellulose and phosphoric acid is 100:3:0.6.

Embodiment 2

[0064] Preparation of modified nano silica:

[0065] (1) Add 6 mL of tetraethyl orthosilicate to 12 mL of absolute ethanol, then add 1.2 mL of HCl solution with a concentration of 2 mol / L dropwise, keep stirring the mixed solution in a water bath at 55°C for 4 hours, and cool to room temperature. Then slowly add 0.5 mL of ammonia solution with a concentration of 2 mol / L, and stir at room temperature for 5 h;

[0066] (2) Add 0.6mL dimethyldiethoxysilane dropwise, react at a constant temperature of 55°C for 22h, wash the obtained product with toluene and absolute ethanol, centrifuge 3 times, and dry to obtain the modified Nano-silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com