A production process of ultra-fine denier direct-spun full-dull polyester filament

A full-dull polyester, production process technology, applied in the melting of filament raw materials, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve poor air permeability, poor unwinding performance, poor dyeing uniformity, etc. problems, to achieve the effect of soft luster, soft touch, and more orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

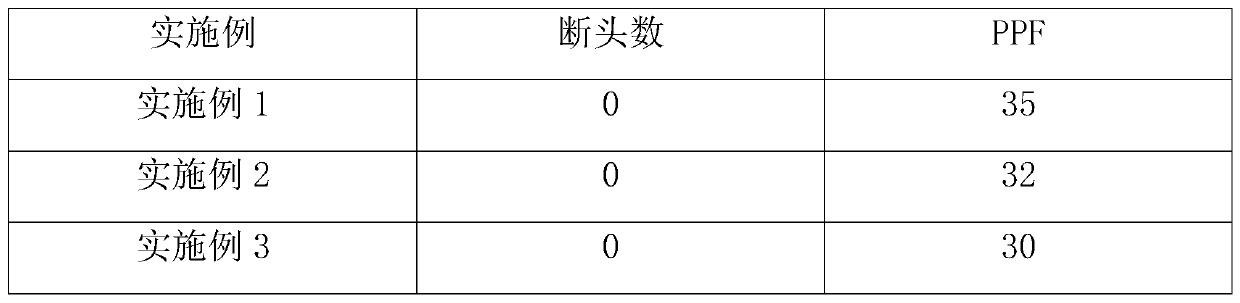

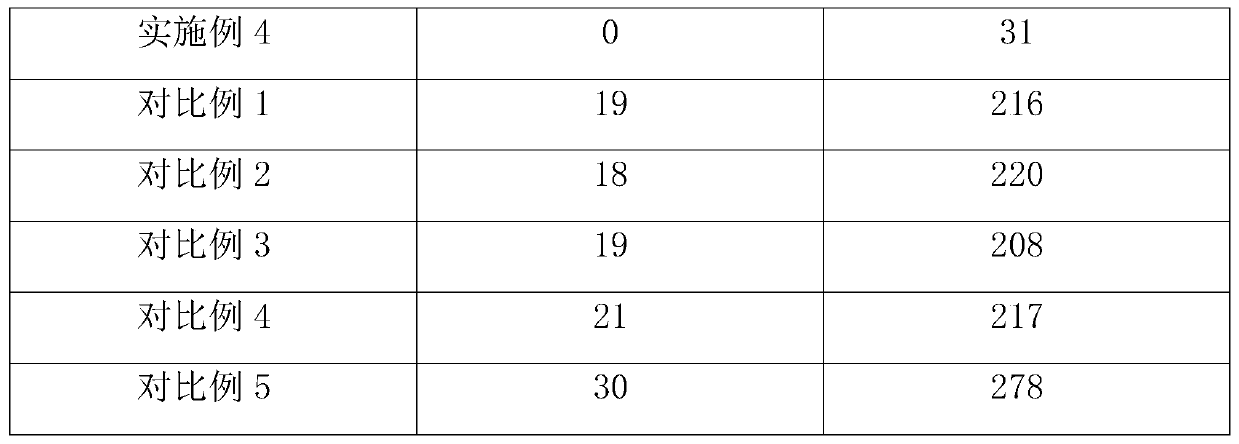

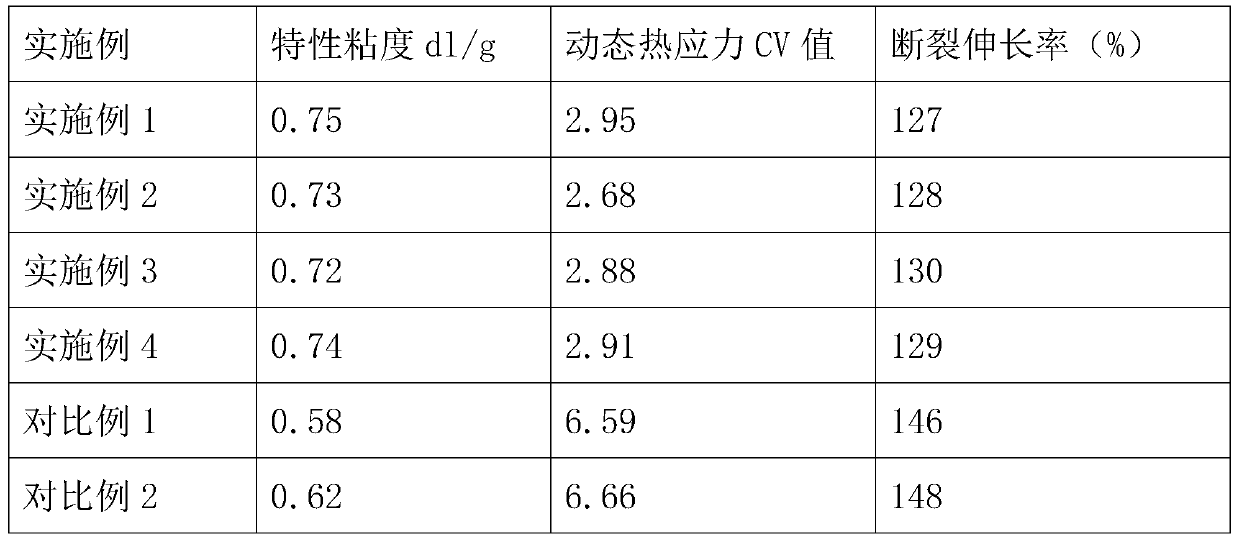

Examples

Embodiment 1

[0031] TiO in this example 2 The addition ratio is 2.8%.

[0032] The production process of superfine denier direct spinning full-dull polyester filament is characterized in that it comprises the following steps:

[0033] 1) Put the raw materials into the polymerization reaction device to generate polyester melt under the action of the catalyst, pass the full-dull polyester melt into the heat exchanger through the heat preservation pipeline for heat exchange, and then pressurize through the booster pump to achieve spinning The required pre-pump pressure;

[0034] 2) Insulate the pressurized full-dull polyester melt, and send it to the spinning box through the pipeline outside the box. The temperature of the spinning box is 290°C, metered by the spinning metering pump, and then passed through the box. The pipe distributes the full-dull polyester melt evenly into the spinning pack;

[0035] 3) The amount of full-dull polyester melt in the spinning assembly entering the metal ...

Embodiment 2

[0041] TiO in this embodiment 2 The addition ratio is 2.9%.

[0042] The production process of superfine denier direct spinning full-dull polyester filament is characterized in that it comprises the following steps:

[0043] 1) Put the raw materials into the polymerization reaction device to generate polyester melt under the action of the catalyst, pass the full-dull polyester melt into the heat exchanger through the heat preservation pipeline for heat exchange, and then pressurize through the booster pump to achieve spinning The required pre-pump pressure;

[0044] 2) Insulate the super-dull polyester melt after pressurization, and send it to the spinning box through the pipeline outside the box. The pipe distributes the full-dull polyester melt evenly into the spinning pack;

[0045] 3) The amount of full-dull polyester melt in the spinning assembly entering the metal sand assembly is 75H / 150g, 50 mesh / 120g;

[0046] 4) From the spinneret at the bottom of the spinning a...

Embodiment 3

[0051] TiO in this embodiment 2 The addition ratio is 3.0%.

[0052] The production process of superfine denier direct spinning full-dull polyester filament is characterized in that it comprises the following steps:

[0053] 1) Put the raw materials into the polymerization reaction device to generate polyester melt under the action of the catalyst, pass the full-dull polyester melt into the heat exchanger through the heat preservation pipeline for heat exchange, and then pressurize through the booster pump to achieve spinning The required pre-pump pressure;

[0054] 2) Insulate the super-dull polyester melt after pressurization, and send it to the spinning box through the pipeline outside the box. The pipe distributes the full-dull polyester melt evenly into the spinning pack;

[0055] 3) The full-dull polyester melt in the spinning assembly enters the metal sand assembly and the amount of sand loaded is 60H / 150g, 40 mesh / 120g;

[0056] 4) From the spinneret at the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com