Composite yarn, cloth knitted thereby and manufacturing method of cloth

A manufacturing method and technology of knitted fabrics, applied in the directions of knitting, weft knitting, fabric elongation, etc., can solve the problems of insignificant advantages of imitation cotton, high price, hard hand feeling, etc., and achieve good fabric drape and increase the use effect. , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

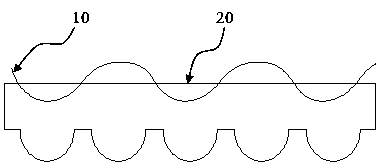

[0014] see figure 1 , the present invention provides an anti-pilling cotton-feeling knitted fabric, which is knitted from ring-spun composite yarns, and the ring-spun composite yarns are composed of a DTY (heavy mesh high elastic yarn) polyester yarn 10 and a 20 POY (pre-oriented yarn) polyester yarns are twisted by a composite twisting machine. During the twisting process, it is necessary to have a twist of 600-800T / M.

[0015] A preferred embodiment of the present invention is that the above-mentioned DTY polyester yarn 10 is a 75D / 48F yarn; the POY polyester yarn 20 is a 75D / 72F yarn; and the ring-spun composite yarn is a 160D / 120F yarn.

[0016] Although the yarns 10 and 20 of the present invention are the same polyester yarn, they have different shrinkage ratios, so the surface of the fabric knitted by the composite yarn is soft to the tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com