Character printing ink of UV-LED ink-jet printing flexible printed circuit board and preparation method thereof

A UV-LED, inkjet printing technology, used in inks, household appliances, applications, etc., can solve the problems of flexibility, insufficient bending resistance, decreased ink adhesion, no adhesion, etc., and achieve low shrinkage effect. , The effect of reducing ink viscosity and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

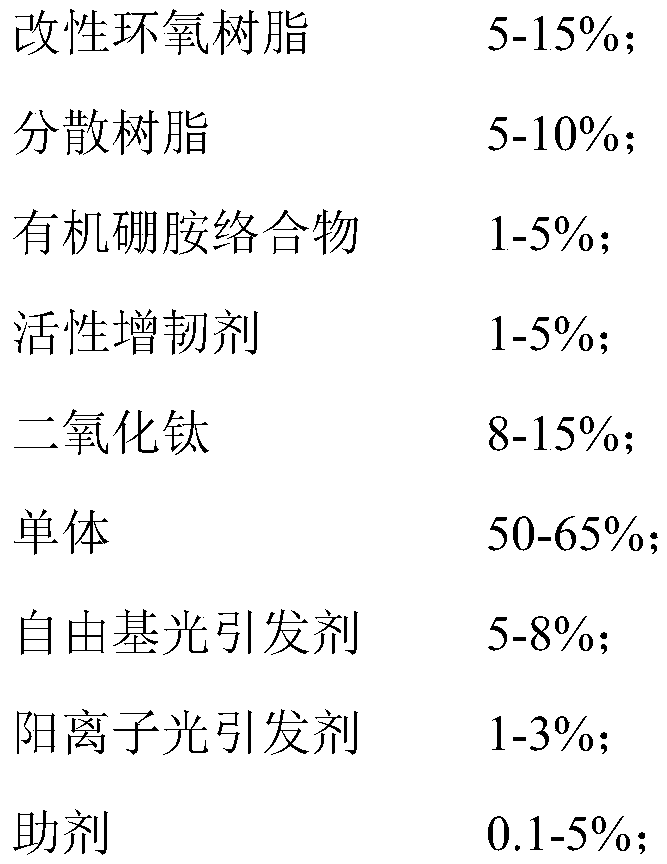

[0035] A kind of UV-LED inkjet prints soft board character ink, comprises the following components by weight percentage:

[0036]

[0037] The preparation method of the above-mentioned UV-LED inkjet printing soft board character ink comprises the following steps:

[0038] (1) Mix hyperbranched urethane acrylate, 10% isobornyl acrylate, 10% 1,6-hexanediol diacrylate, 15% trimethylolpropane triacrylate, BYK111, and titanium dioxide, and grind to particle size D50 is less than 300nm, filter to obtain white nano-color paste;

[0039] (2) Mix photoinitiator 907, photoinitiator TPO, Irgacure261, remaining isobornyl acrylate, remaining 1,6-hexanediol diacrylate, and remaining trimethylolpropane triacrylate to obtain a mixed solution ;

[0040] (3) The white nano-color paste obtained in step (1), the mixed solution obtained in step (2), polyurethane modified epoxy resin, organic boron amine complex, C8-C10 alcohol glycidyl ether, BYK-307, Mix BYK085 evenly, and then filter throu...

Embodiment 2

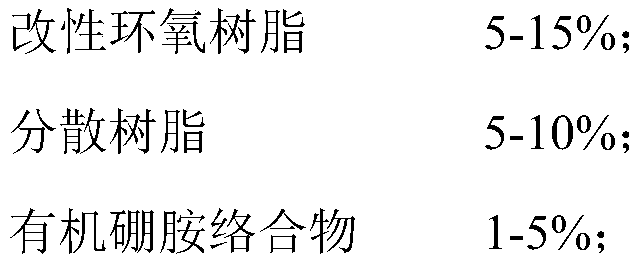

[0046] A kind of UV-LED inkjet prints soft board character ink, comprises the following components by weight percentage:

[0047]

[0048]The preparation method of the above-mentioned UV-LED inkjet printing soft board character ink comprises the following steps:

[0049] (1) Mix aliphatic urethane acrylate, 12% cyclohexyl methacrylate, 15% 1,6-hexanediol diacrylate BYK180, and titanium dioxide, grind until the particle size D50 is less than 300nm, and filter to obtain white nano-color pulp;

[0050] (2) Mix photoinitiator 369, photoinitiator TPO, Irgacure261 with remaining cyclohexyl methacrylate and remaining 1,6-hexanediol diacrylate to obtain a mixed solution;

[0051] (3) The white nano-color paste obtained in step (1), the mixed solution obtained in step (2), polyurethane modified epoxy resin, organic boron amine complex, C8-C10 alcohol glycidyl ether, BYK-361N, Mix BYK088 evenly, and then filter through a 1 micron filter membrane to obtain UV-LED inkjet printing sof...

Embodiment 3

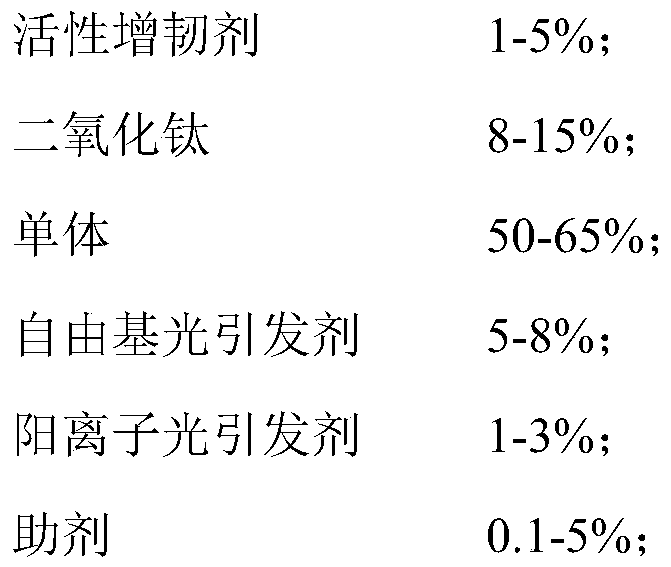

[0057] A kind of UV-LED inkjet prints soft board character ink, comprises the following components by weight percentage:

[0058]

[0059]

[0060] The preparation method of the above-mentioned UV-LED inkjet printing soft board character ink comprises the following steps:

[0061] (1) Mix hyperbranched urethane acrylate, 30% 1,6-hexanediol diacrylate, 30% triethyltrimethylolpropane triacrylate, BYK111, and titanium dioxide, and grind until the particle size D50 is less than 300nm, Filter to obtain white nano color paste;

[0062] (2) Mix photoinitiator 369, photoinitiator TPO, Irgacure261 with remaining 1,6-hexanediol diacrylate and remaining triethyltrimethylolpropane triacrylate to obtain a mixed solution;

[0063] (3) The white nano-color paste obtained in step (1), the mixed solution obtained in step (2), polyurethane modified epoxy resin, organic boron amine complex, C12-C14 alcohol glycidyl ether, BYK-354, TEGO Airex 900 is mixed evenly, and then filtered through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com