Titanium-copper based brazing filler metal for brazing titanium alloy and stainless steel, and preparation method and application thereof

A technology of titanium alloy and brazing filler metal, which is applied in the field of titanium-copper-based brazing filler metal composition formulation, can solve the problems of restricting the production and application of brazing filler metal, the highly toxic beryllium element, etc., and achieve the convenience of experiment and production assembly, and good wettability With fluidity, the effect of reducing build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

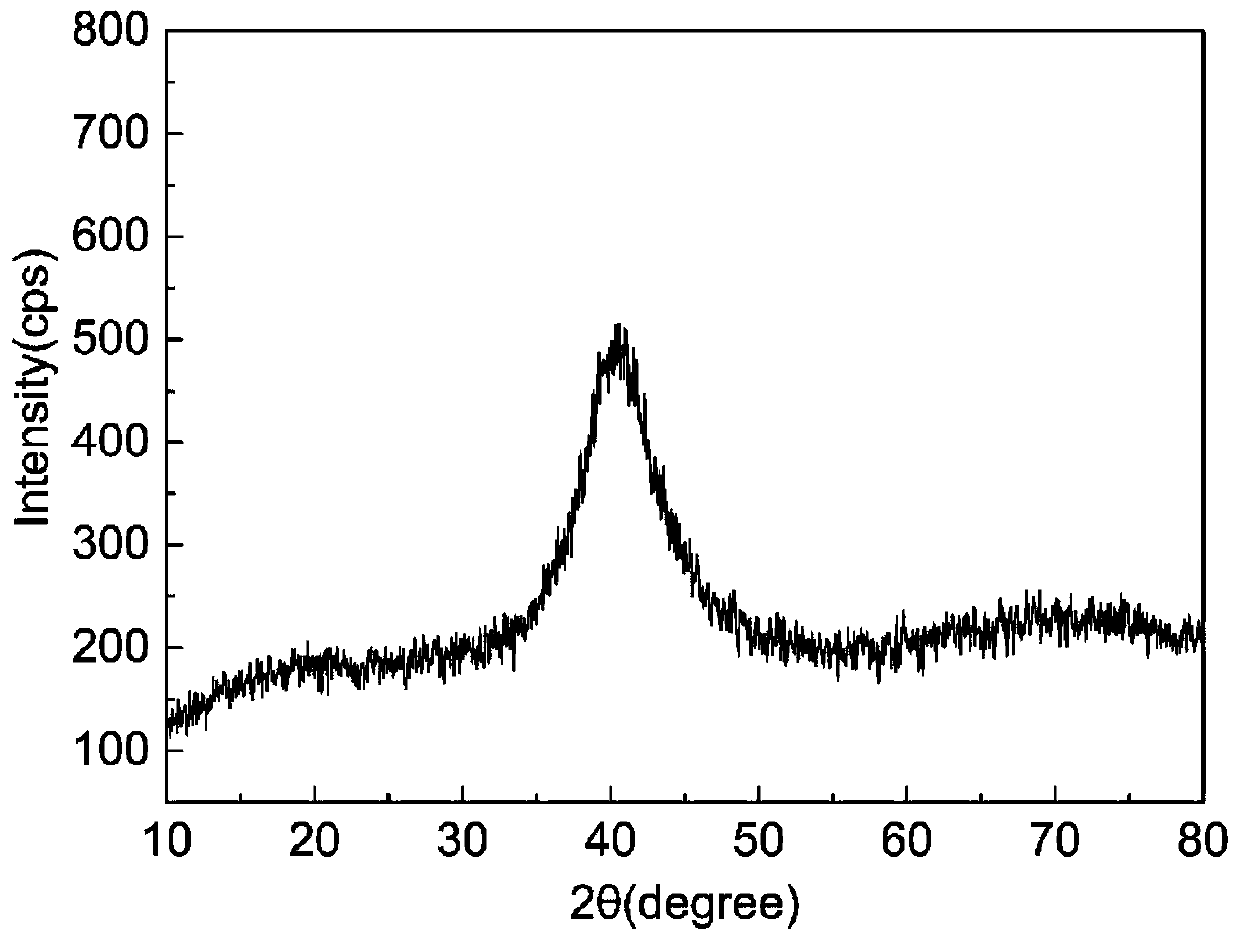

[0033] Design the composition of titanium-copper-based solder: Based on the 24-electron criterion of cluster and connecting atom model and amorphous alloy composition design, select the TiCu eutectic point in the binary phase diagram, and obtain the cluster formula [Ti-Cu 6 Ti 8 ]Cu 3 , and replace the Ti and Cu atoms in the cluster formula with Zr and Ni atoms, respectively, so as to improve the amorphous forming ability of the solder.

[0034] This embodiment is finally based on the cluster formula [Ti-Cu 6 Ti 8 ]Cu 3 Get [Ti-Cu 6 Ti 5 Zr 3 ]CuNi 2 , and its corresponding alloy mass percentage expression is Ti 25.5 Zr 24.4 Cu 39.7 Ni 10.4 .

[0035] Melting alloy ingots: Mix raw materials (purity above 99.9%) according to a predetermined mass percentage, and use a vacuum arc melting furnace for melting with a vacuum degree of at least 6.0×10 -3 Pa, smelting 4 times to ensure an alloy ingot with uniform composition.

[0036] Preparation of titanium-copper-based so...

Embodiment 2

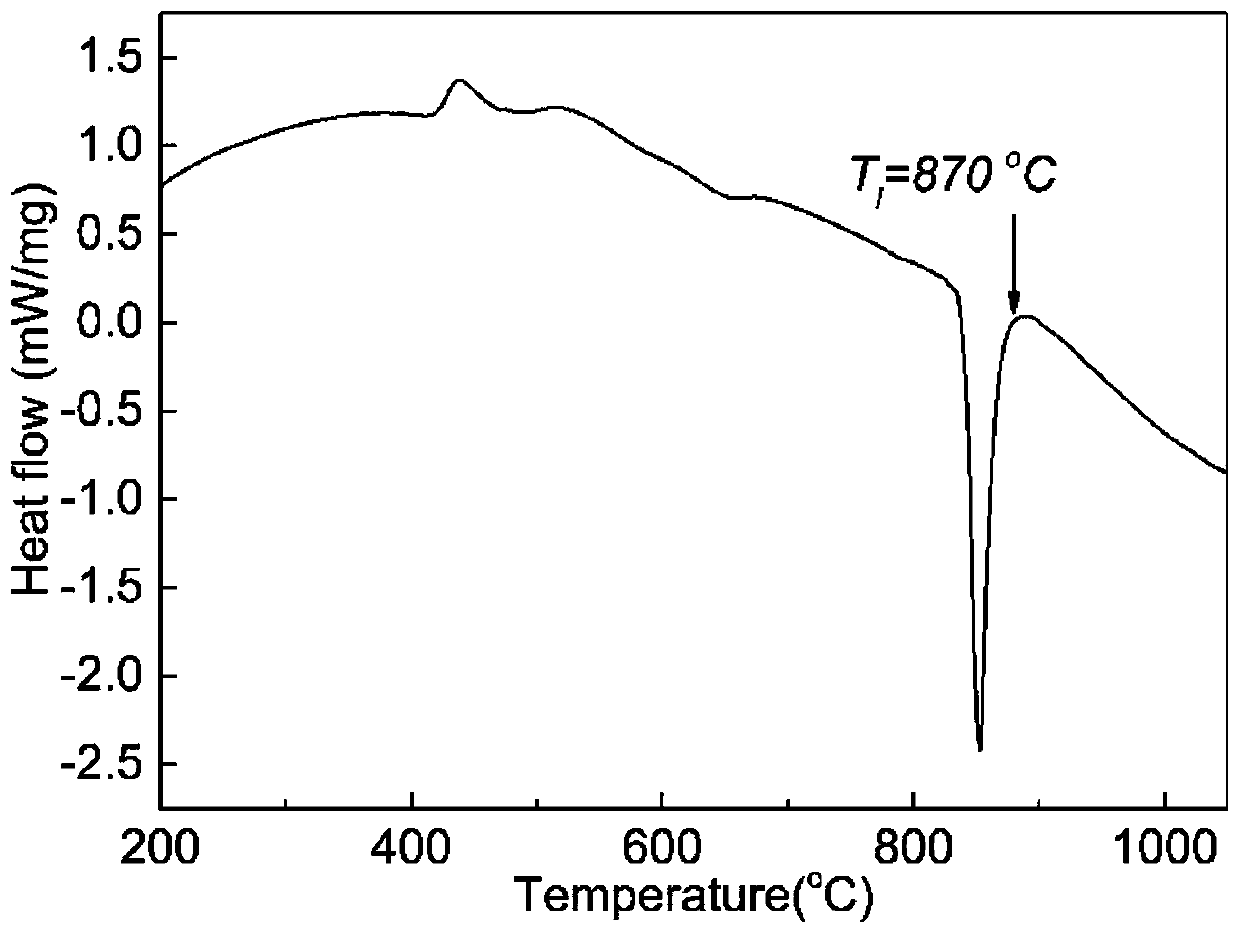

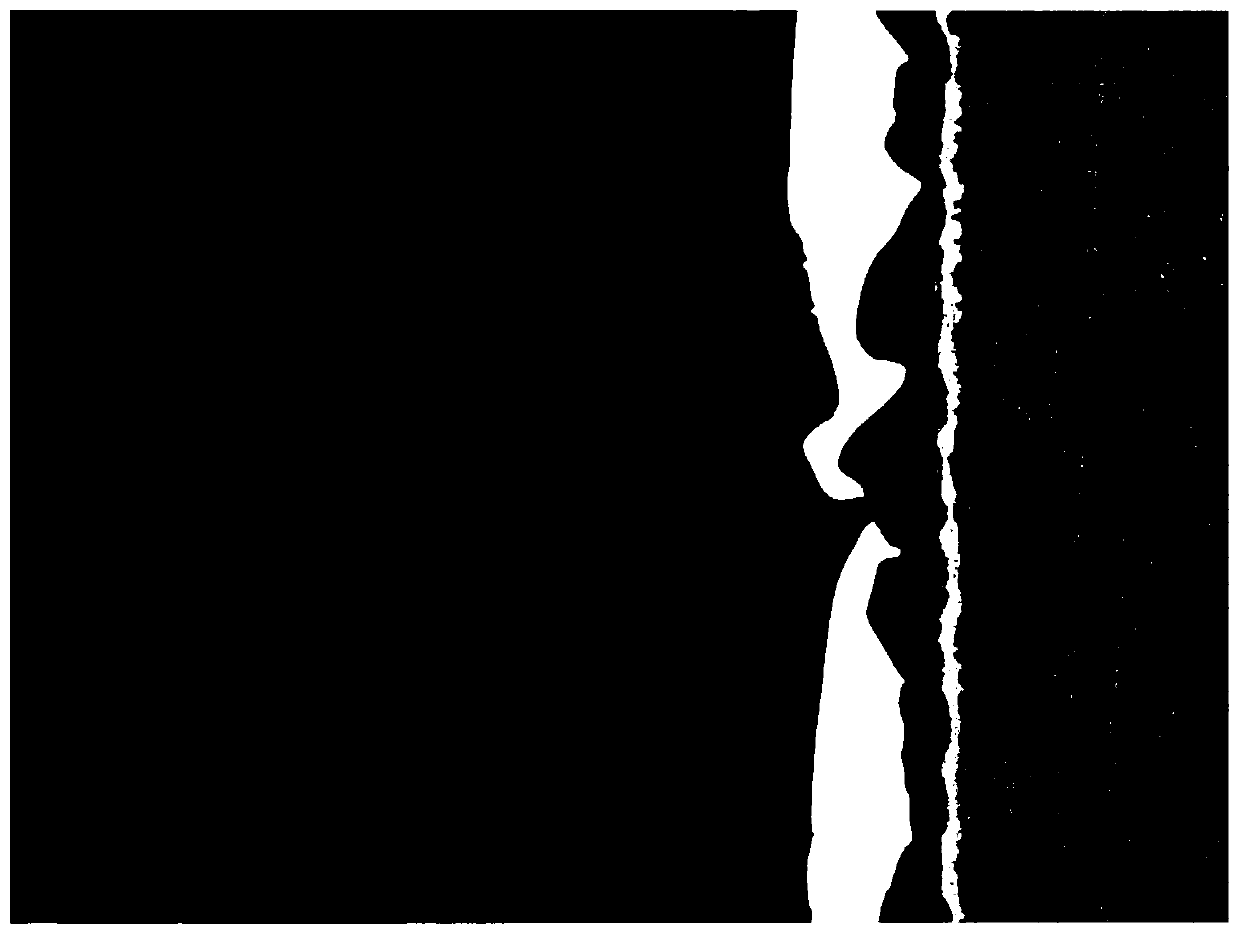

[0042] Ti of embodiment 1 25.5 Zr 24.4 Cu 39.7 Ni 10.4 Performance test of titanium-copper-based amorphous solder: the prepared Ti 25.5 Zr 24.4 Cu 39.7 Ni 10.4 Titanium-copper based amorphous solder cut into 5×5mm 2 The small pieces are placed between the samples to be welded. For brazing experiments, the assembled samples were placed in a vacuum brazing furnace and vacuumed to 6×10 -3 Start heating after Pa. First heat to 800°C at 10°C / min and hold for 10 minutes, then heat to 900°C at 20°C / min and hold for 10 minutes, and finally cool the sample to room temperature with the furnace. The room temperature shear strength of the brazed joint is 220MPa. Figure 4 It is the structure diagram of the brazed joint in this embodiment. It can be seen from the figure that a large number of lamellar structures are formed at the front edge of the titanium alloy matrix, indicating that Ti 25.5 Zr 24.4 Cu 39.7 Ni 10.4 Vigorous diffusion and metallurgical reactions occurred bet...

Embodiment 3

[0045] Prepare Ti according to the preparation method of brazing filler metal in embodiment 1 25.6 Zr 24.5 Cu 34.3 Ni 15.6 Titanium-copper based solder foil strips were tested for soldering.

[0046] Test experiment:

[0047] Cut the TC4 titanium alloy and 316L stainless steel wire into 5×5×4mm 3 and 15×10×4mm 3 The sample, the surface to be welded with 600 # Smooth it with sandpaper, and finally ultrasonically clean it in acetone for 10 minutes.

[0048] Sample assembly Cut the solder into 5×5mm 2 Place the small piece between the samples to be welded for the brazing experiment. Place the assembled sample in a vacuum brazing furnace and vacuumize to 6×10 -3 Start heating after Pa. First heat to 800°C at a rate of 10°C / min and hold for 10 minutes, then heat to 930°C at 20°C / min and hold for 10 minutes, and finally the sample is cooled to room temperature with the furnace.

[0049] By adopting this implementation method, a safe and reliable titanium alloy / stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com