Medical one-component room temperature vulcanization silicone rubber and preparation method thereof

A technology of room temperature vulcanization and silicone rubber, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of irritating odor, high toxicity, poor adhesion, etc., and achieve the content of small molecule volatiles The effect of low cost, simple preparation method and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

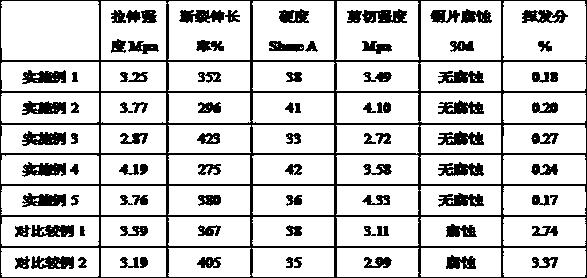

Examples

Embodiment 1

[0045] Add toluene to the hydroxyl-terminated polydimethylsiloxane and stir well, let it stand until it is completely separated, separate the solvent layer, and distill off the residual solvent to obtain a low-volatile hydroxyl-terminated polydimethylsiloxane, that is, a low-volatility polydimethylsiloxane 107 Silicone rubber.

[0046] 100 parts of low-volatility 107 silicone rubber with a viscosity of 3000mPa·S and a specific surface area of 200m2 treated with silazane 2 Add 20 parts of hydrophobic fumed white carbon black per g to a high-speed mixer, heat up to 160°C and dry for 20 minutes; then move it into a planetary mixer for evacuation and defoaming for 45 minutes, then add 6 parts of ethyl methyl trilactate silane, and dry in a vacuum Mix under the same conditions for 30 minutes; then add 2 parts of γ-aminopropyltriethoxysilane and 0.1 part of tetraisopropyl titanate, and mix in vacuum for 40 minutes; finally, pack and seal under the protection of inert gas to obtain...

Embodiment 2

[0049] Add xylene and ethyl acetate to hydroxyl-terminated polydimethylsiloxane and stir well, let it stand until it is completely separated, separate the solvent layer, and distill off the residual solvent to obtain low-volatility hydroxyl-terminated polydimethylsiloxane Alkane, that is, low volatility 107 silicone rubber.

[0050] 100 parts of low-volatility 107 silicone rubber with a viscosity of 5000mPa·S and a specific surface area of 300m2 treated with silazane 2 Add 20 parts of hydrophobic fumed silica / g into a high-speed mixer, heat up to 160°C and dry for 30 minutes; then move it into a planetary mixer to vacuum and defoam for 30 minutes, then add 6 parts of vinyl trilactate silane, and dry under vacuum conditions Mix for 60 minutes; then add 1 part of γ-aminopropyltriethoxysilane, 2 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and bis(ethyl acetoacetate) dititanate 0.5 part of isopropyl ester, mixed in vacuum for 30 minutes; finally, packaged and sealed und...

Embodiment 3

[0053] Add carbon tetrachloride to the hydroxyl-terminated polydimethylsiloxane and stir well, let it stand until it is completely separated, separate the solvent layer, and distill off the residual solvent to obtain a low-volatility terminal hydroxyl polydimethylsiloxane. Namely low volatility 107 silicone rubber.

[0054] Add 100 parts of low-volatility 107 silicone rubber with a viscosity of 50000mPa·S and 15 parts of hydrophilic fumed silica into a high-speed mixer, heat up to 160°C and dry for 25 minutes; 5 parts of ethyl trilactate silane and 5 parts of vinyl trilactate ethyl silane, mixed under vacuum for 45 minutes; then add 2 parts of γ-chloropropyl trimethoxysilane and 1 part of zinc dibutyl dithiophosphate , mixed in vacuum for 60 minutes; finally, packaged and sealed under the protection of an inert gas to obtain medical one-component room temperature vulcanized silicone rubber.

[0055] The obtained one-component room temperature vulcanized silicone rubber was pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com