Beta-SiAlON ceramic with complex shape, and preparation method thereof

A complex shape, ceramic technology, applied in the field of complex shape β-SiAlON ceramics and its preparation, can solve problems such as the inability to meet the rapid prototyping and processing of complex components, the difficulty of forming complex structural ceramic materials, and the large processing volume, so as to avoid disasters. Fracture, material system convenience, the effect of increasing the work of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

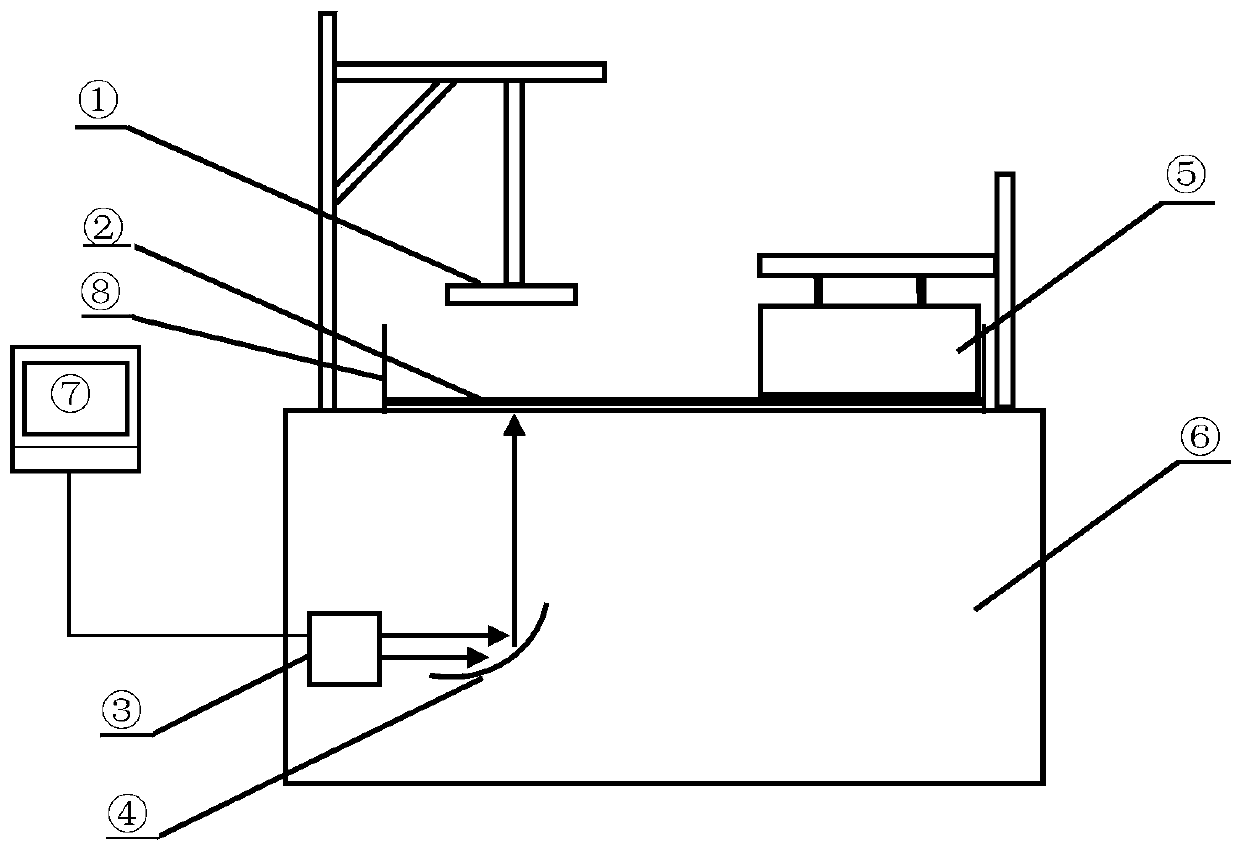

Image

Examples

Embodiment 1

[0034] A method for preparing complex-shaped β-SiAlON ceramic materials based on light-curing molding technology, comprising the following specific steps:

[0035] S1. Weigh EPTA, UDPA, PUA, and n-octanol respectively by mass fraction 25%: 20%: 25%: 30%, and mix them uniformly to obtain a premixed liquid, then weigh ceramic raw material powder (including nitriding Silicon, aluminum nitride and aluminum oxide, among them, the average particle size of silicon nitride is 750-900nm, 1000-1300nm; the average particle size of aluminum nitride is 800-950nm, 1000-1300nm; the average particle size of aluminum oxide is 700 ~ 850nm, 1100 ~ 1500nm) into the premix, and mix evenly to obtain ceramic slurry;

[0036] S2. Put the uniformly stirred ceramic slurry into an ultrasonic disperser for ultrasonic dispersion for 20-30 minutes, then put the ultrasonically dispersed ceramic slurry into a plastic tank, and ball mill for 2 hours at a speed of 350-400r / min ;

[0037]S3. Take out the ball...

Embodiment 2

[0042] The difference between this embodiment and Example 1 is that EPTA, UDPA, PUA, and n-octanol are weighed by mass fraction in the layered ceramic matrix composite material prepared by light curing technology, and the mass percentage is 25%: 20%: 25%: 30%, and mix the premix evenly.

Embodiment 3

[0044] The difference between this embodiment and Example 1-2 is that after converting the solid phase content of the ceramic particles into mass percentage, the mass fraction of the ceramic particles in the slurry is 50-70% (relative to the ceramic slurry).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com