Preparation method and use of MnO@ nitrogen-doped porous carbon nanocomposite

A technology of nitrogen-doped porous carbon and nanocomposites, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to increase electrochemical lithium storage performance, high specific surface area, fast and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the preparation method of MnO@nitrogen-doped porous carbon nanocomposite, comprises the following steps:

[0032] (1) Dissolve 0.428g of trimesic acid into 50ml of 80°C deionized water, keep the water bath at constant temperature for a period of time, wait for it to completely dissolve, dissolve 0.495g of manganese acetate into 50ml of 80°C deionized water, pour the manganese acetate solution into In the trimesic acid solution, stir and react at a constant temperature for 30 minutes to obtain a metal-organic framework precursor, namely Mn-BTC powder;

[0033] (2) Dry the Mn-BTC powder obtained above in a constant temperature drying oven, and the temperature of the constant temperature drying oven is 80 ° C;

[0034] (3) Calcining the metal-organic framework precursor obtained in (1) in an ammonia atmosphere, the calcination temperature is 800°C, the holding time is 2 hours, and the heating rate is 2°C / min, and MnO@nitrogen-doped porous carbon can be obtain...

Embodiment 2

[0035] Embodiment 2, the preparation of MnO@porous carbon nanocomposite

[0036] The metal-organic framework precursor obtained in (1) of Example 1 was calcined in an argon atmosphere, the calcination temperature was 800°C, the holding time was 2 hours, and the heating rate was 2°C / min, to obtain MnO@porous carbon nanocomposite thing;

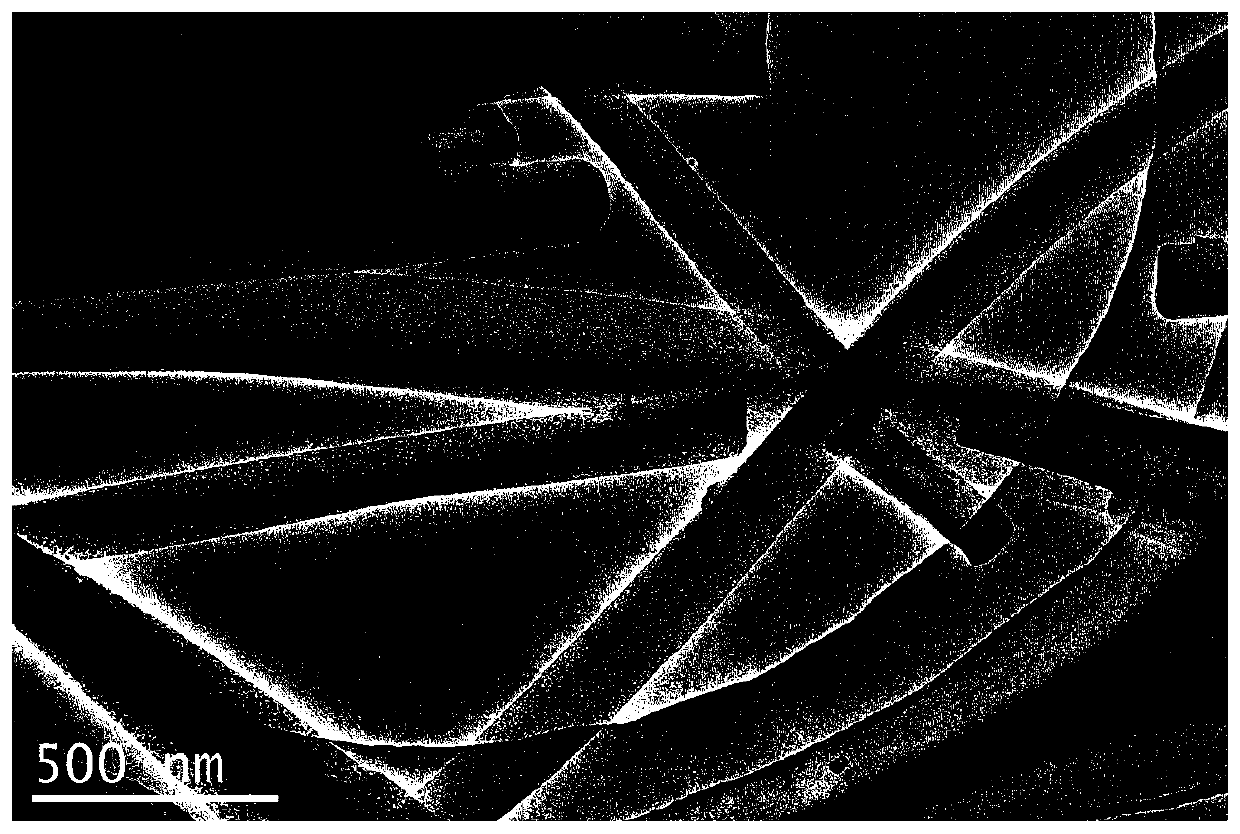

[0037] figure 1 with figure 2 The SEM and TEM photos of the MnO@nitrogen-doped porous carbon nanocomposite obtained in Example 2 above show that the diameter of the material is between 200-400 nm.

[0038] image 3 with Figure 4 The SEM and TEM photos of the MnO@porous carbon nanocomposite obtained in Example 2 show that the material is a solid nanowire with a porous structure.

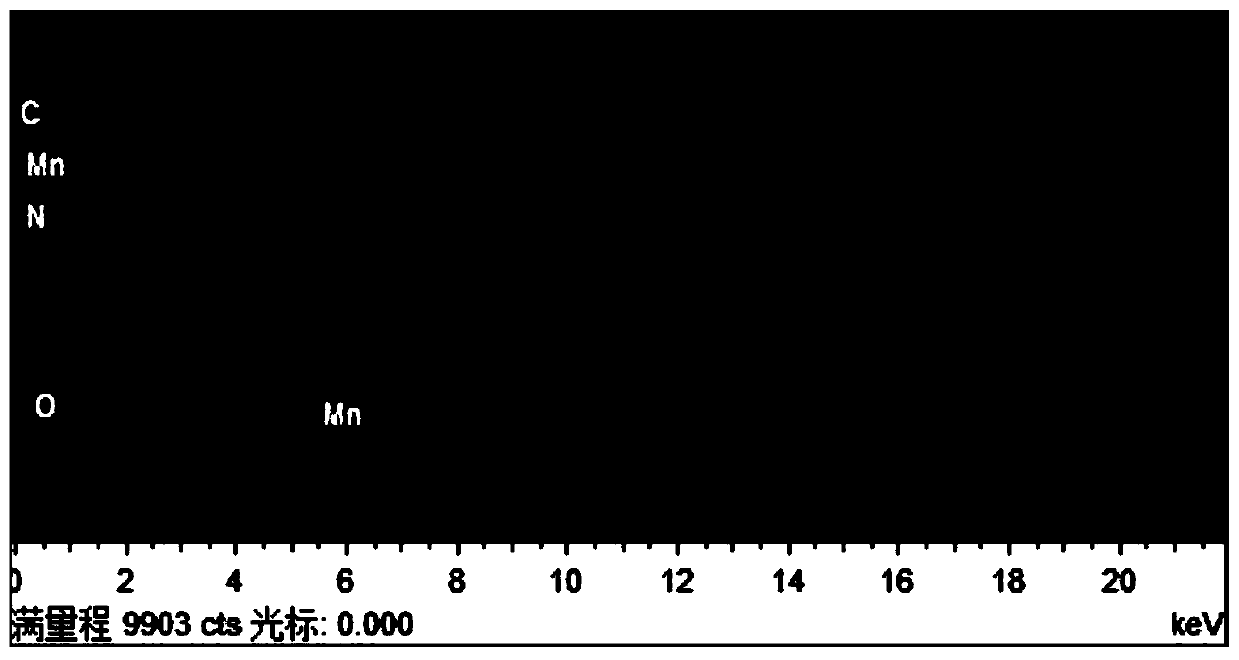

[0039] Figure 5 It is the EDS image of the sample obtained in Example 1. It can be seen that after the metal-organic framework precursor is calcined in an ammonia atmosphere, the product contains a large amount of nitrogen, and the doping of nitrogen is conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com