Preparation method of polyurethane curing agent

A polyurethane curing agent and ester solvent technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems affecting product quality, affecting curing agent performance, reducing resin compatibility, etc., to achieve excellent yellowing resistance , good economic value, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

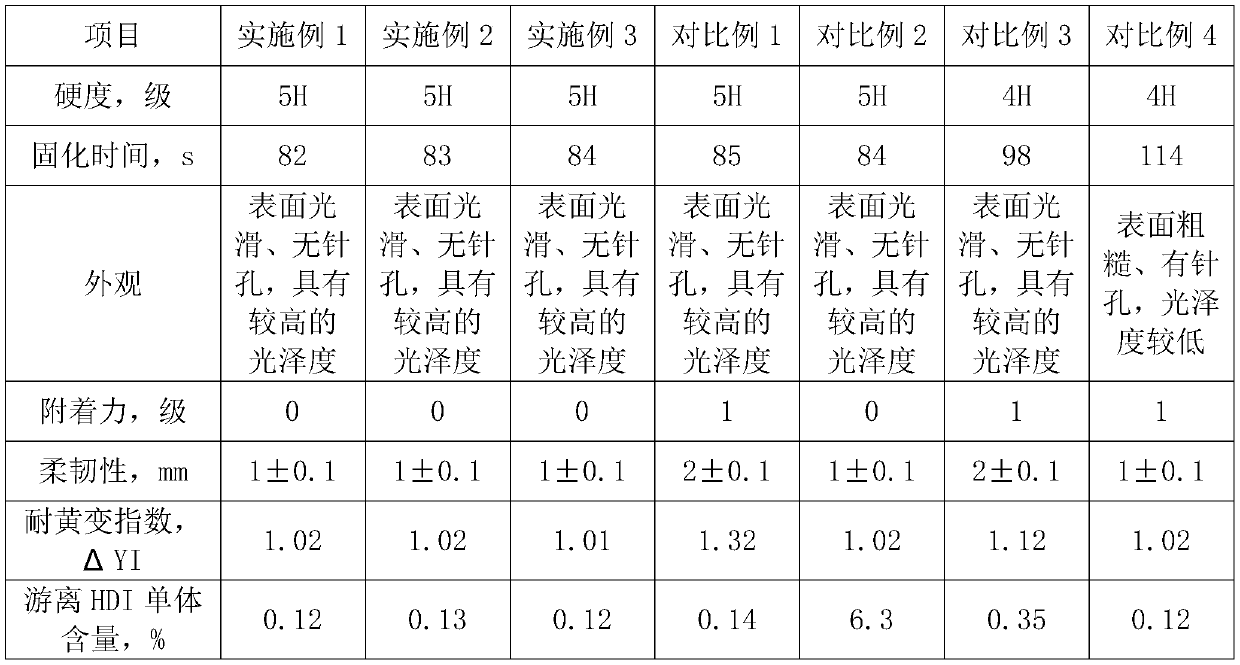

Examples

preparation example 1

[0042] Preparation example 1: ① Dehydrate trimethylolpropane and dimethylolpropionic acid at a temperature of 100°C and a vacuum of 0.06MPa for 1.5h;

[0043] ②Stir 10kg of dehydrated trimethylolpropane and 10kg of n-butyl acetate at a temperature of 70°C for 10min to obtain mixture A; mix 4kg of dehydrated dimethylolpropionic acid and 1kg of triethylamine at 60°C Stirring for 10 min under the temperature, to obtain the mixture B;

[0044] ③Under the protection of nitrogen, take 35kg of hexamethylene diisocyanate, 10kg of polyethylene glycol, 0.1kg of dibutyltin dilaurate, and 0.1kg of dibutyltin diacetate, and stir at a temperature of 50°C at 60 drops / min Mixture A was added dropwise while stirring, and mixture B was added dropwise at a rate of 60 drops / min after the addition of mixture A; then the temperature was raised to 60°C, and the reaction was kept for 2 hours; the temperature was continued to rise to 80°C, and phosphoric acid barrier Polymerizing agent 0.1kg, keep wa...

preparation example 2

[0046] Preparation example 2: ① Dehydrate trimethylolpropane and dimethylolpropionic acid for 1.8 hours at a temperature of 105°C and a vacuum of 0.075MPa;

[0047] ② Stir 12.5kg of dehydrated trimethylolpropane and 12.5kg of n-butyl acetate at a temperature of 75°C for 15min to obtain mixture A; mix 5kg of dehydrated dimethylolpropionic acid and 2kg of triethylamine Stirring at a temperature of 65°C for 15 minutes to obtain mixture B;

[0048] ③Under the protection of nitrogen, take 37.5kg of hexamethylene diisocyanate, 12.5kg of polyethylene glycol, 0.125kg of dibutyltin dilaurate, and 0.125kg of dibutyltin diacetate, and stir at a temperature of 53°C. Add mixture A dropwise at a rate of 60 drops / min while stirring, and add mixture B dropwise at a rate of 60 drops / min after the addition of mixture A; Add 0.15kg of benzoyl chloride polymerization inhibitor, keep warm for 35min, then cool down to 45°C to obtain crude product;

[0049] ④ Use a thin-film evaporator to separate...

preparation example 3

[0050] Preparation Example 3: ① Dehydrate trimethylolpropane and dimethylolpropionic acid for 2 hours at a temperature of 110°C and a vacuum of 0.09MPa;

[0051] ②Stir 15kg of dehydrated trimethylolpropane and 15kg of n-butyl acetate at 80°C for 20min to obtain mixture A; mix 6kg of dehydrated dimethylolpropionic acid and 3kg of triethylamine at 70°C Under the temperature, stir 20min, obtain mixture B;

[0052] ③Under nitrogen protection, take 40kg of hexamethylene diisocyanate, 15kg of polyethylene glycol, 0.15kg of dibutyltin dilaurate, and 0.15kg of dibutyltin diacetate, and stir at a temperature of 55°C at 60 drops / min Mixture A was added dropwise while stirring, and mixture B was added dropwise at a rate of 60 drops / min after the addition of mixture A; then the temperature was raised to 65°C, and the reaction was kept for 3 hours; the temperature was continued to rise to 90°C, and phosphoric acid resist Polymerizing agent 0.2kg, keep warm for 40min, then cool down to 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com