Maintenance method of heavy-duty anti-corrosion seal wrapping on the surface of steel components

A steel component, heavy-duty anti-corrosion technology, which is applied in the field of heavy-duty anti-corrosion seal wrapping protection on the surface of steel components, and in the field of steel structure surface corrosion protection, which can solve problems such as lack of bonding strength, unsatisfactory, high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

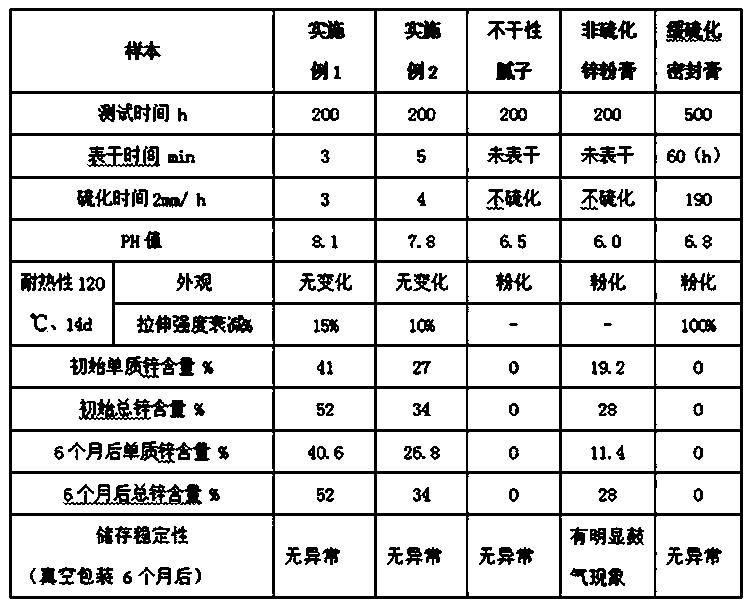

[0068] Processing and preparation of quick-drying zinc-rich silane-modified polymer sealant, the raw material composition and weight parts of the quick-dry zinc-rich silane-modified polymer sealant in Example 1-2 are shown in Table 1, wherein SAX510 is Japanese Kanka Sanjia Oxygen-terminated silane-modified polymer resins, STP and SPUR trimethoxy-terminated silane-modified polymer resins are alkaline resins with a pH value, and the amount of basic additives can be reduced accordingly.

[0069] Table 1 Example 1-Example 2 The composition of each raw material and parts by weight Unit: parts by weight

[0070]

[0071] Weigh each raw material according to the weight part of the material in Table 1, first use the connection N 2 The pipeline of the storage device is slowly and continuously filled with clean and dry N into the clean and dry double planetary mixer tank 2 , then first put the non-alcoholic plasticizer into it, then add highly active silane-modified polymer resin, ...

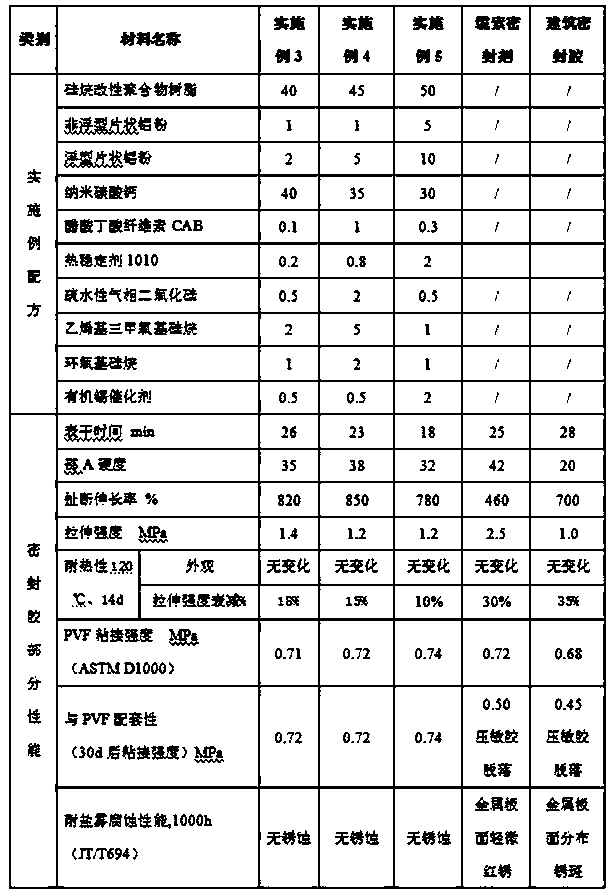

Embodiment 3-5

[0077] Preparation of vulcanized aluminum-rich silane-modified polymer sealant. See Table 3 for the raw material composition and parts by weight of the vulcanized aluminum-rich silane-modified polymer sealant in Examples 3-5.

[0078] Table 3 The composition and parts by weight of each material in Embodiment 3-5 Unit: parts by weight

[0079]

[0080] Weigh each material according to the weight of vulcanized aluminum-rich silane-modified polymer sealant materials in Table 3, first put the silane-modified polymer resin into a clean and dry double planetary mixer, and then add hydrophobic fumed silica, Nano-calcium carbonate, cellulose acetate butyrate, heat stabilizer 1010, 50-70% by weight of vinyltrimethoxysilane, vacuumize and stir and disperse at a speed of 50-100rpm for 10-30min; then gradually heat to 50- 70°C, stir at a high speed of 1000-1500rpm for 30-90min, until the sealant paste is fine and uniform, then cool it down to below 40°C; then add non-leafing flake alum...

Embodiment 6

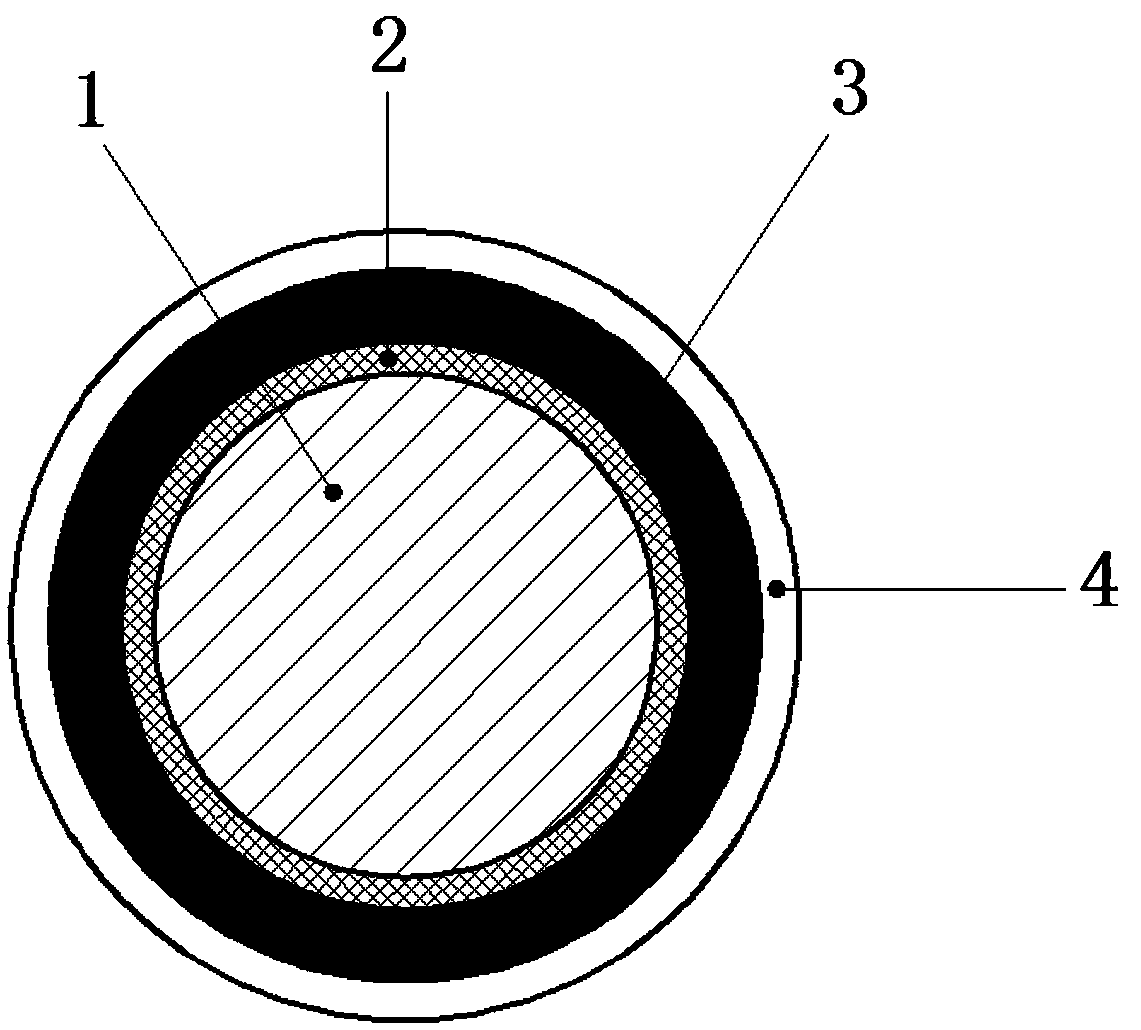

[0083] Such as figure 1 As shown, the surface heavy-duty anti-corrosion seal wrapping maintenance method of steel components in a petrochemical plant, the specific steps are as follows:

[0084] The first step substrate treatment

[0085] Firstly, remove the heavy-duty anti-corrosion coating of the steel component base 1 that has failed, peeled off, etc., and manually polish and clean the surface rust and other pollutants, and the surface cleanliness reaches St3 level.

[0086] The second step is to prepare the inner sealing protective layer

[0087] After the surface of the substrate is cleaned and dried, immediately apply a layer of fast-drying zinc-rich silane modified polymer sealant in Example 1, and fill and scrape the corrosion pits, defects, and rough surfaces on the surface of the steel component substrate 1 caused by corrosion to form The inner sealing protective layer 2 has an average thickness of about 0.1-0.5mm.

[0088] The third step is to prepare the outer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com