Metal micro/nano wire array and preparation method thereof

A nanowire array, metal technology, applied in metal material coating process, microstructure technology, microstructure device and other directions, can solve the problem of unable to obtain high aspect ratio micro/nanowires, etc., achieve high recycling rate, improve The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

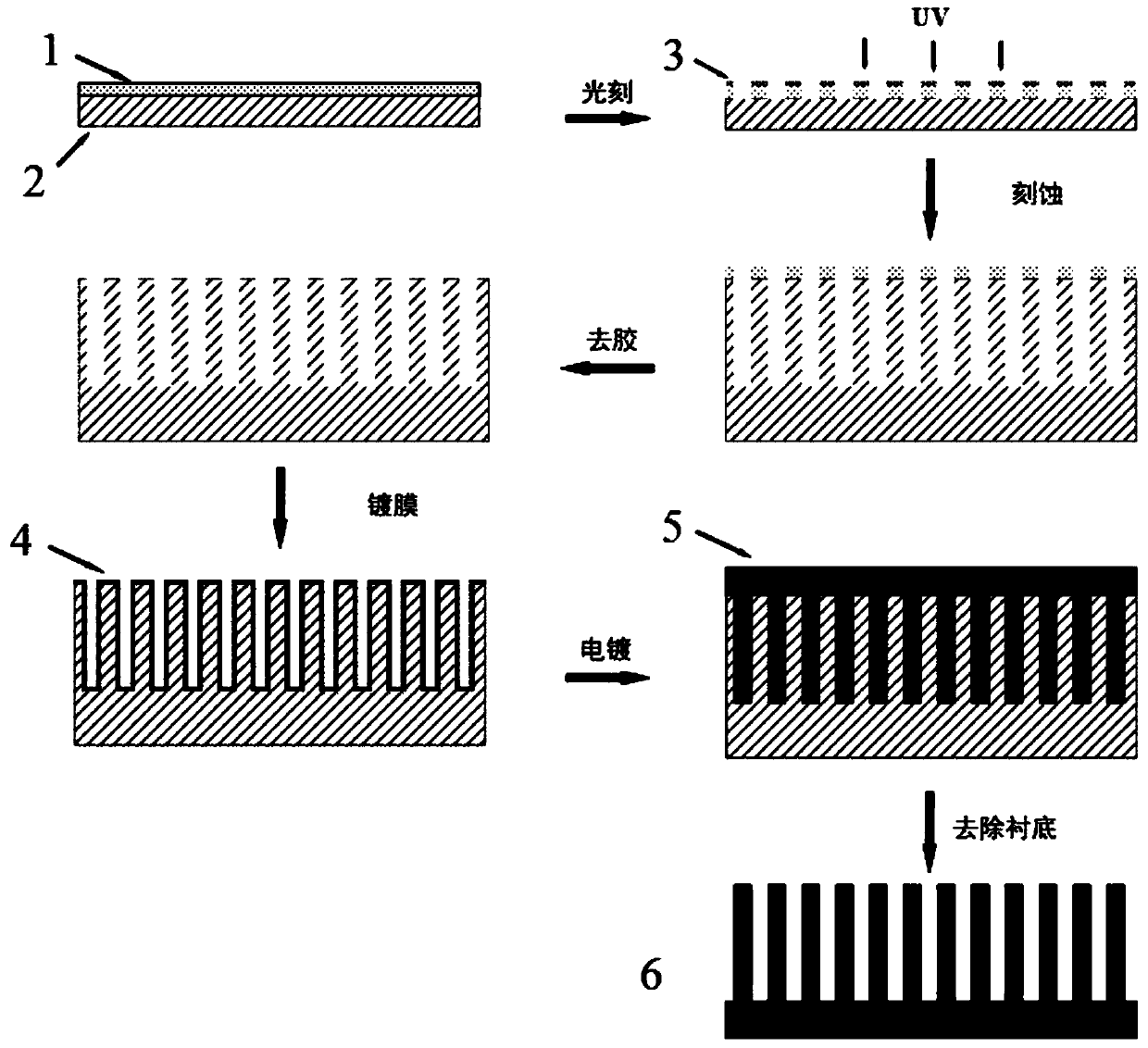

[0042] This embodiment provides a method for preparing nickel micron line arrays by photolithography micro-nano processing technology, such as figure 1 Shown is the flow chart of the present embodiment method, and concrete steps are as follows:

[0043] Preparation of silicon micron deep holes: ordinary silicon wafers are spin-coated with photoresist at a rate of 4000r / min for 40s and a film thickness of 1.5μm. A photolithographic template with a diameter of 2 μm and a period of 6 μm was used for photolithography to obtain photoresist holes with a diameter of 2 μm and a period of 6 μm. Use photoresist as a mask to perform deep silicon etching (Northern Huachuang HSE200 deep silicon etching machine), and the etching gas is SF 6 , the shielding gas is C 4 f 8 , the etching rate is 0.2μm / s, the etching time is 120s, and the etching depth is 20μm. Use acetone to ultrasonically remove the photoresist on the surface of the structure for 5 minutes to obtain silicon micron deep hol...

Embodiment 2

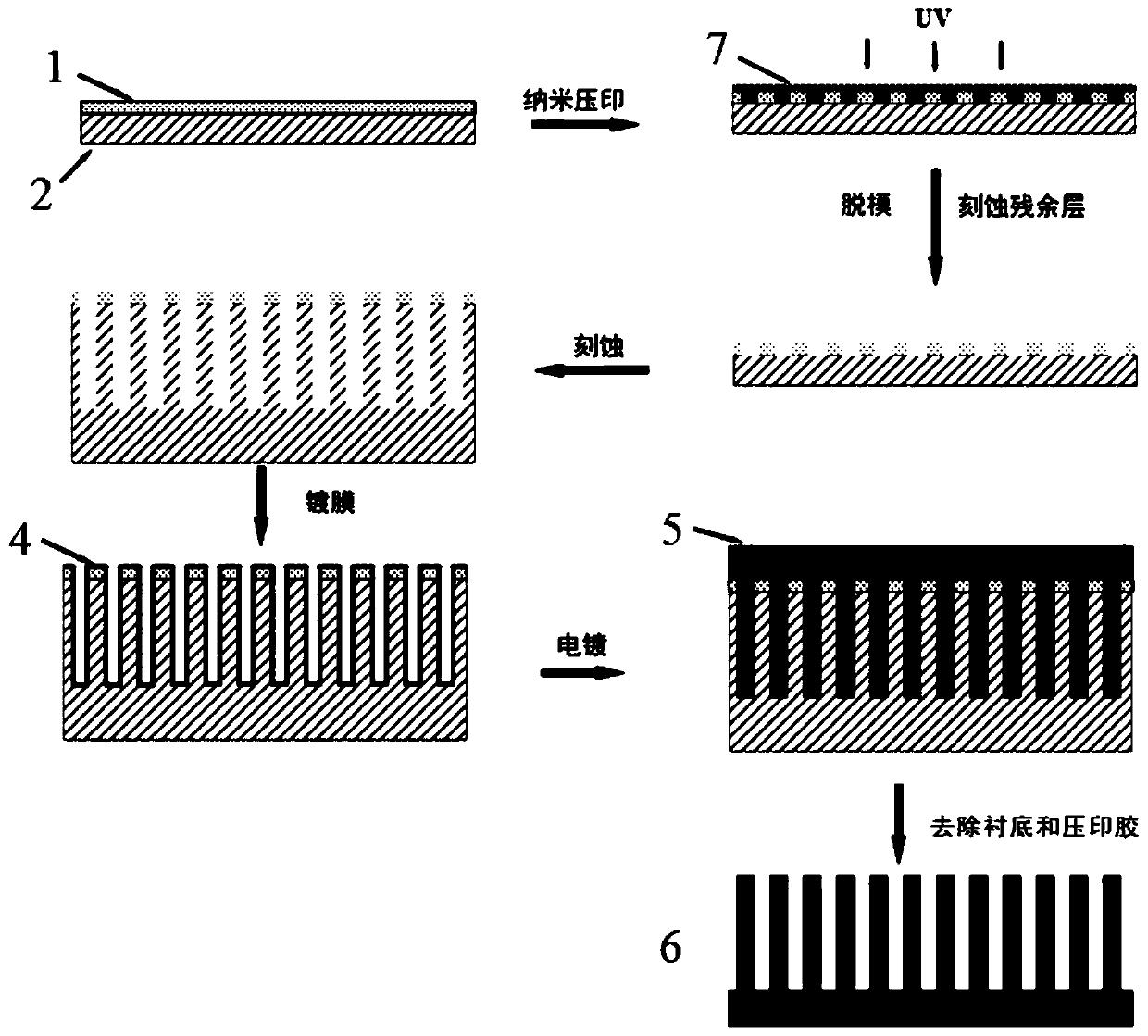

[0048] This embodiment provides a method for preparing nickel nanowire arrays by nanoimprinting technology, such as figure 2 Shown is the flow chart of the present embodiment method, and concrete steps are as follows:

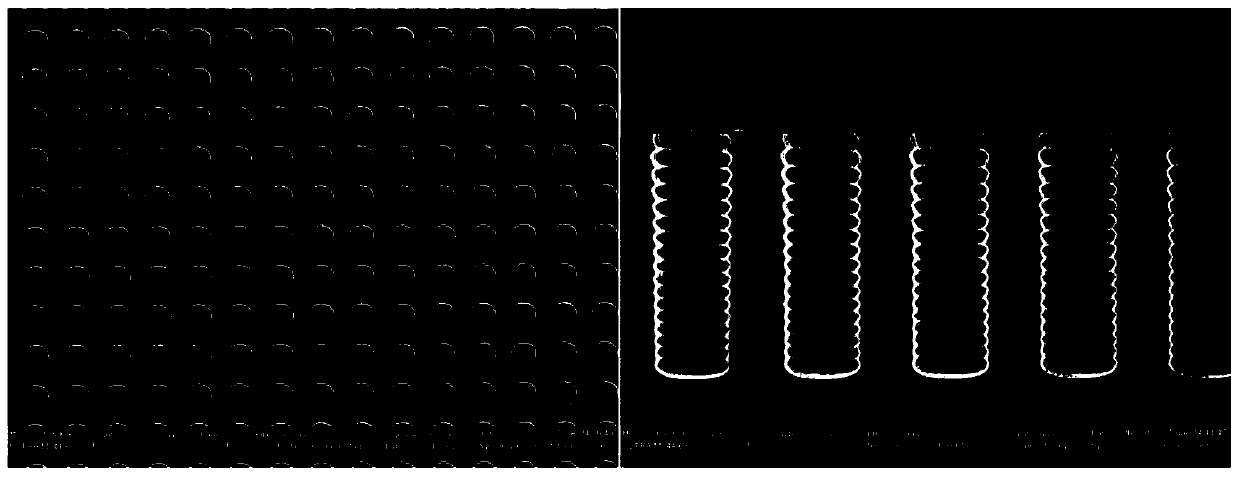

[0049] Preparation of silicon nano-deep holes: Ordinary silicon wafers are spin-coated with UV-curable imprinting glue, the speed is 2000r / min, the time is 40s, the film thickness is 150nm, and the PDMS soft template with a diameter of 500nm and a period of 1000nm is used for imprinting. After UV-curing , forming embossed glue holes with a diameter of 500nm and a period of 1000nm, and using an inductively coupled plasma etching machine (ULVAC CE300I) to etch and remove the residual layer. Use imprinting glue as a mask to perform deep silicon etching, and the etching gas is SF 6 , the shielding gas is C 4 f 8 , the etching rate is 0.2 μm / s, the etching time is 60 s, and the etching depth is 10 μm. Obtain silicon nano-deep pores, such as Figure 5 shown.

...

Embodiment 3

[0054] This embodiment provides a method for preparing a copper micron line array by photolithography micro-nano processing technology, and the specific steps are as follows:

[0055] Preparation of silicon micron deep holes: ordinary silicon wafers are spin-coated with photoresist at a rate of 3000r / min for 40s and a film thickness of 1.8μm. A photolithographic template with a diameter of 5 μm and a period of 10 μm was taken for photolithography to obtain photoresist holes with a diameter of 5 μm and a period of 10 μm. Use photoresist as a mask for deep silicon etching, and the etching gas is SF 6 , the shielding gas is C 4 f 8 , the etching rate was 0.15 μm / s, the etching time was 400 s, and the etching depth was 40 μm. The photoresist on the surface of the structure was removed by ultrasonication of acetone for 5 minutes, and silicon micron deep holes were obtained.

[0056] Preparation of metallic copper micron wires: Evaporate a layer of metallic copper on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com