Gas sensor based on metal molybdate nano composite material and preparation method thereof

A nanocomposite material, gas sensor technology, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor timeliness and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The gas sensor based on the metal molybdate nanocomposite that the present embodiment relates to has 2 discrete ring-shaped gold electrodes on the outer surface of the Al 2 o 3 Insulated ceramic tube 1, passing through Al 2 o 3 The nickel-cadmium alloy coil 2 inside the insulating ceramic tube and coated on Al 2 o 3 The outer surface of the insulating ceramic tube and the sensitive material thin film 3 on the annular gold electrode are formed, and the sensitive material is a metal molybdate nanocomposite material;

[0055] The concrete preparation technology of described metal molybdate nanocomposite material is:

[0056] Step 1: Prepare molybdenum sulfide powder: prepare MoS by hydrothermal synthesis of ammonium molybdate, thiourea, ammonium fluoride and citric acid 2 suspension, and then the MoS 2 Preparation of MoS by suspension washing, sonication, centrifugation and drying 2 powder;

[0057] Step 2: preparing a semiconducting metal oxide suspension: prepari...

Embodiment 2

[0061] The nano-flower-like In based on this embodiment involves 2 (MoO 4 ) 3 @In 2 o 3 The ethanol gas sensor of the nanocomposite material, it is made of Al with 2 discrete annular gold electrodes on the outer surface 2 o 3 Insulating ceramic tube 1, passing through Al 2 o 3 The nickel-cadmium alloy coil 2 inside the insulating ceramic tube and coated in Al 2 o 3 The outer surface of the insulating ceramic tube and the sensitive material film 3 on the ring-shaped gold electrode are composed of a nano-flower-like In 2 (MoO 4 ) 3 @In 2 o 3 nanocomposites;

[0062] The nanoflower-like In 2 (MoO 4 ) 3 @In 2 o 3 The specific preparation process of nanocomposites is as follows:

[0063] Step 1: Prepare molybdenum sulfide powder: prepare MoS by hydrothermal synthesis of ammonium molybdate, thiourea, ammonium fluoride and citric acid 2 suspension, and then the MoS 2 Preparation of MoS by suspension washing, sonication, centrifugation and drying 2 Powder, the sp...

Embodiment 3

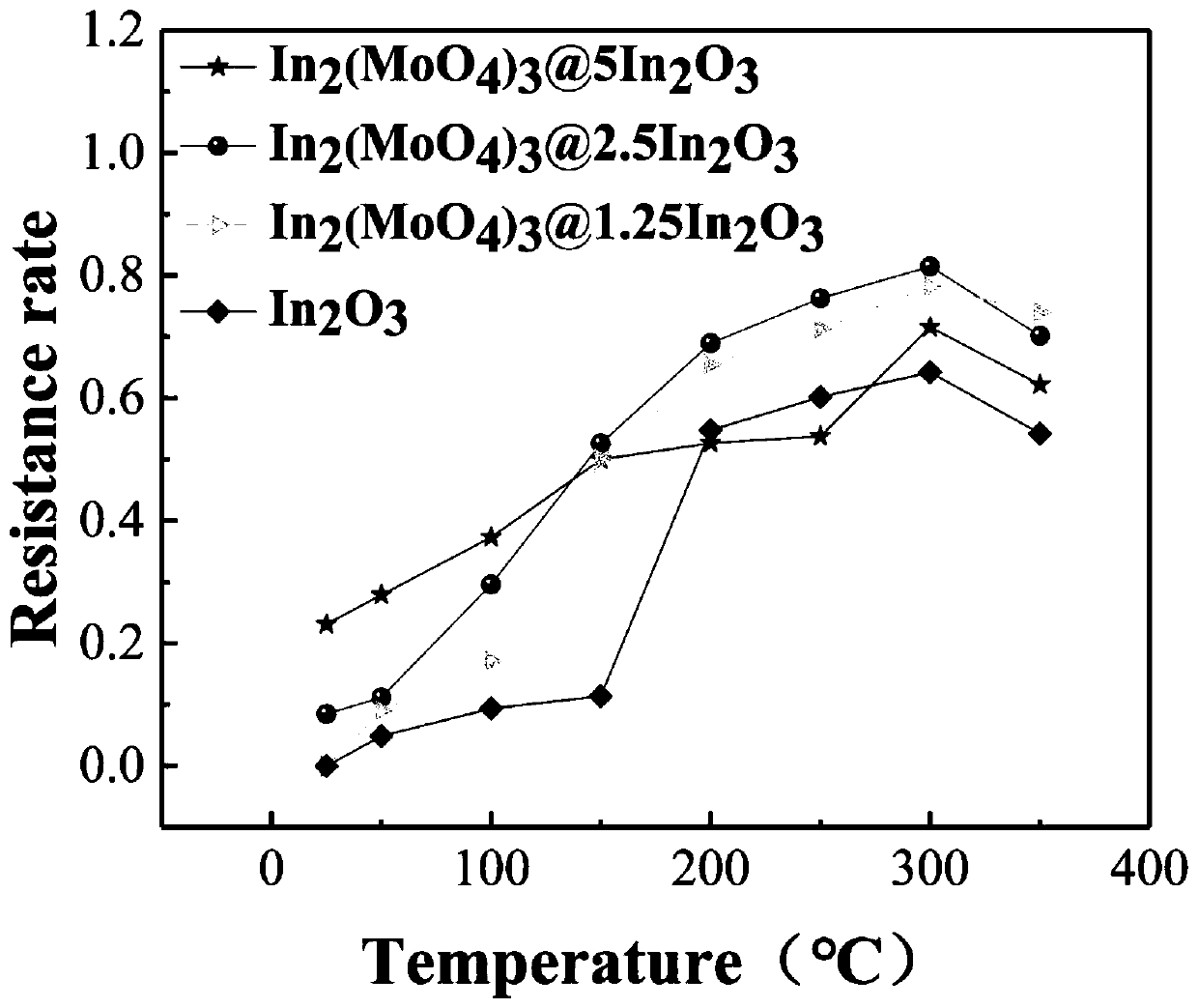

[0082] In this example, the In prepared in Example 2 2 (MoO 4 ) 3 @5In 2 o 3 、In 2 (MoO 4 ) 3 @2.5In 2 o 3 、In 2 (MoO 4 ) 3 @1.25In 2 o 3 and In 2 o 3 Mix with 3-8 drops of deionized water respectively to form a paste, then spread the paste evenly on the gas sensor alumina ceramic tube 1, and dry it at 60°C for 12 hours to obtain In 2 (MoO 4 ) 3 @5In 2 o 3 、In 2 (MoO 4 ) 3 @2.5In 2 o 3 、In 2 (MoO 4 ) 3 @1.25In 2 o 3 and In 2 o 3 Four gas sensors.

[0083] Such as image 3 Shown in 2 (MoO 4 ) 3 @5In 2 o 3 、In 2 (MoO 4 ) 3 @2.5In 2 o 3 、In 2 (MoO 4 ) 3 @1.25In 2 o 3 and In 2 o 3 The gas sensing performance of the four gas sensors is closely related to the operating temperature, which is caused by the gas reaction kinetics, such as chemisorbed oxygen and the interaction between the detected gas and the n-type semiconductor In 2 o 3 The electron gain and loss relationship between, when the temperature is 300 °C, based on In 2 (Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com