A kind of preparation method of sleeper spring bar

A technology for spring bars and sleepers, which is applied in the field of metal functional material preparation, can solve the problems of increased maintenance cost, short service cycle, environmental pollution, etc., and achieves the effects of long fatigue life, cost saving, and environmental pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

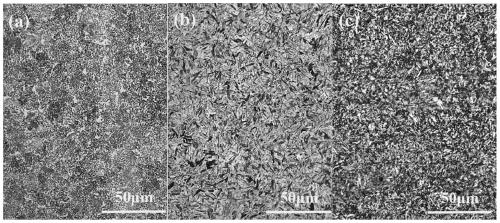

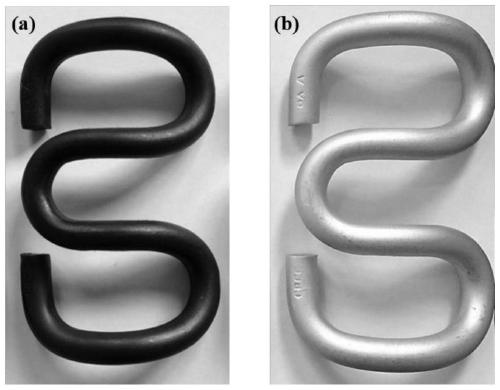

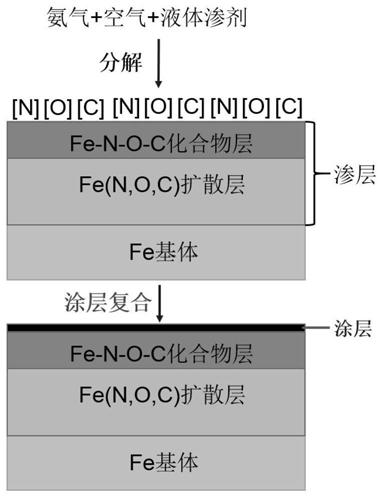

[0023] A method for preparing a sleeper spring bar. The sleeper spring bar is made of a spring steel billet containing vanadium, and the mass percentages of the spring steel billet are as follows: carbon C: 0.56%; silicon Si: 1.80%; manganese Mn: 0.80 %; Vanadium V: 0.15%; Copper Cu: 0.05%; Aluminum Al: 0.08%; Sulfur S: 0.011%; Phosphorus P: 0.012%; Iron Fe: 96.537%; The induction vacuum electric furnace is smelted by gas protection electroslag, and then hot forged and hot rolled to make spring steel billets. The hot rolled spring steel billets need to remove the surface decarburization layer and scale, and the austenite grain size is 7 grades; The spring steel billet is used as the raw material, and the sleeper clip is drawn and formed after intermediate frequency induction heating. The formed sleeper clip is quenched by gas atomization. The quenching medium is water and air. The quenched sleeper clip is placed into the gas co-infiltration furnace for surface treatment; under...

Embodiment 2

[0030] A method for preparing a sleeper clip, the spring steel used in the clip has the following mass percentages of the main components: carbon C: 0.58%; silicon Si: 2.0%; manganese Mn: 1.0%; vanadium V: 0.18%; copper Cu: 0.0%; aluminum Al: 0.06%; sulfur S: 0.010%; phosphorus P: 0.010%; Hot forging and hot rolling are made into spring steel billets. The spring steel billets after hot rolling need to remove the surface decarburization layer and scale, and the austenite grain size is 7 grades. Among them, the impurity element oxygen content O: 10ppm; nitrogen content For N: 12ppm. The spring billet is used as the raw material, heated to a temperature of 930±10°C by medium-frequency induction heating, and then shaped into type I-A spring bars. After forming, the temperature is 840±5°C, and then gas atomized quenching is carried out. The hardness is HRC58. Under the condition of 480°C, tempering and gas co-infiltration treatment are carried out on the quenched elastic bar at th...

Embodiment 3

[0032]A method for preparing a sleeper clip, the spring steel used in the clip has the following mass percentages of the main components: carbon C: 0.60%; silicon Si: 2.0%; manganese Mn: 1.2%; vanadium V: 0.20%; copper Cu: 0.06%; aluminum Al: 0.0%; sulfur S: 0.010%; phosphorus P: 0.010%; Hot forging and hot rolling are made into spring steel billets. The spring steel billets after hot rolling need to remove the surface decarburization layer and scale, and the austenite grain size is 7 grades. Among them, the impurity element oxygen content O: 10ppm; nitrogen content For N: 14ppm. The spring billet is used as the raw material, heated to a temperature of 930±10°C by medium-frequency induction heating, and then shaped into type I-A spring bars. After forming, the temperature is 840±5°C, and then gas atomized quenching is carried out. The hardness is HRC60. Under the condition of 500°C, tempering and gas co-infiltration treatment are carried out on the quenched elastic bar at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com