Environment-friendly polycarbonate/polyester composite material and preparation method and application thereof

A technology of polyester composite material and polycarbonate, which is applied in the field of intelligent irrigation control well room, which can solve the problem of unsatisfactory mechanical strength, chemical corrosion resistance and aging resistance, low safety of intelligent irrigation control well room, glass fiber reinforced plastic and cast iron The materials are not environmentally friendly and the environment can avoid anti-aging and flame-retardant properties, improve interfacial compatibility, and improve comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

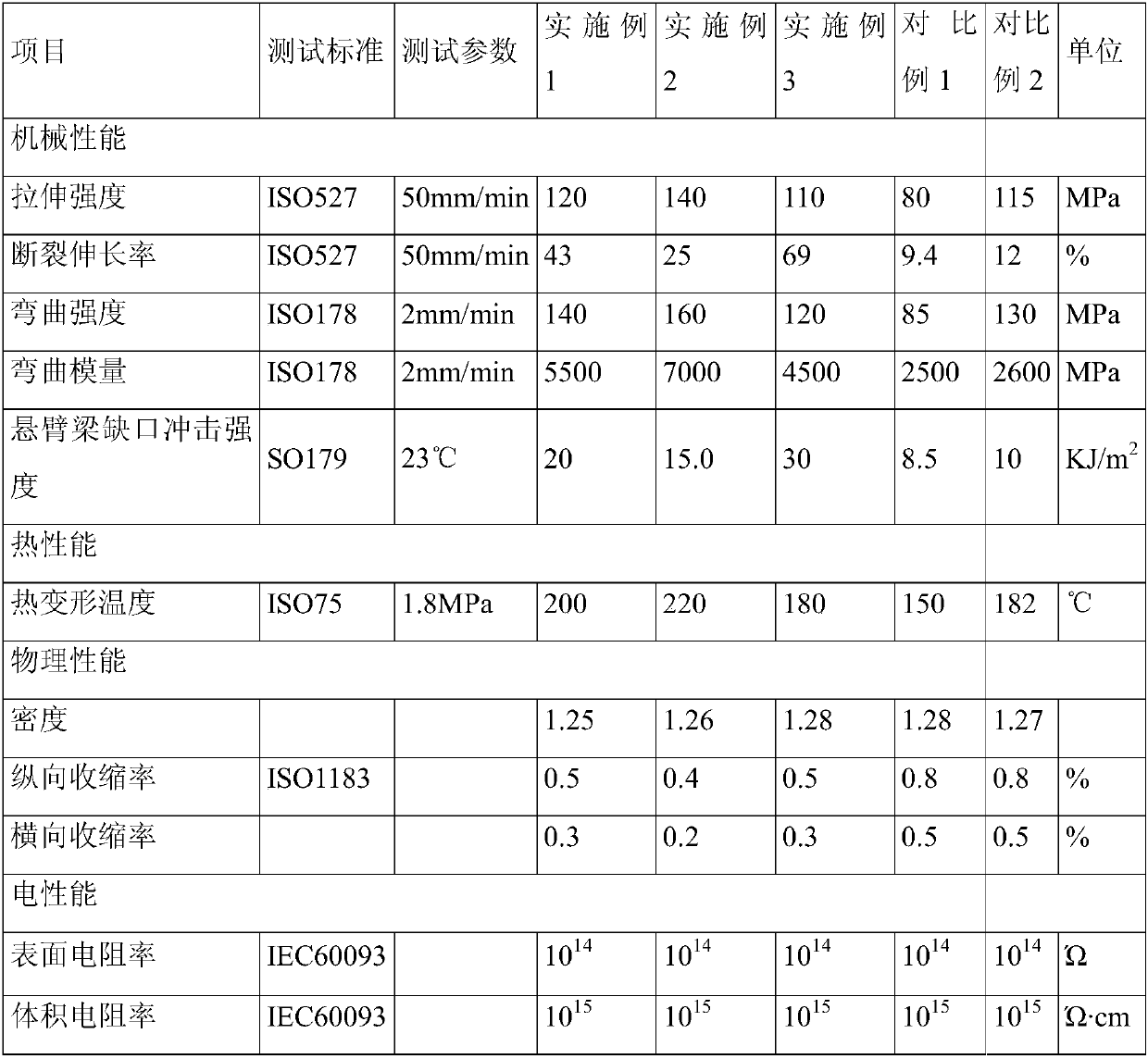

Examples

Embodiment 1

[0045] Prescription: 30 parts by weight of polycarbonate (PC), 30 parts by weight of polybutylene terephthalate (PBT) as polyester, 20 parts by weight of glass fiber, 2 parts by weight of triethyl phosphate as transesterification inhibitor Parts, 5 parts by weight of polyethylene grafted maleic anhydride (Shanghai Rizhisheng Company) as a compatibilizer, ethylene-methyl acrylate-glycidyl methacrylate copolymer (available from France Ake Ma company) 2 parts by weight, 15 parts by weight of melamine aluminum polyphosphate (purchasing Clariant company) as flame retardant, 0.3 parts by weight of anti-UV agent (UV360), 0.15 parts by weight of antioxidant (1098), coupling agent ( KH570) 0.15 parts by weight, silicone powder 0.2 parts by weight as a lubricant.

[0046] Preparation:

[0047] 1) Put the formulated amount of PC, polyester and toughener into a high-speed mixer for pre-mixing for 1-3 minutes, then add the formulated amount of coupling agent and mix for 2-4 minutes to ful...

Embodiment 2

[0054] Prescription: 30 parts by weight of polycarbonate (PC), 30 parts by weight of polyethylene terephthalate (PET) as polyester, 20 parts by weight of glass fiber, 2 parts by weight of triethyl phosphate as transesterification inhibitor Parts, 5 parts by weight of polyethylene grafted maleic anhydride (Shanghai Rizhisheng Company) as compatibilizer, 2 parts by weight of n-butyl acrylate-glycidyl ester copolymer (Akema Company of France) as toughening agent , 15 parts by weight of aluminum hypophosphite (purchase Clariant company) as flame retardant, 0.3 parts by weight of anti-UV agent (UV360), 0.15 parts by weight of antioxidant (1098), 0.15 parts by weight of coupling agent (KH570), lubricated agent (silicone powder) 0.2 parts by weight.

[0055] The preparation method is the same as in Example 1.

Embodiment 3

[0057] Prescription: 30 parts by weight of polycarbonate (PC), 30 parts by weight of poly(butylene terephthalate-co-butylene adipate) (PBAT) as polyester, 20 parts by weight of glass fiber, as 2 parts by weight of triethyl phosphate of transesterification inhibitor, 5 parts by weight of polyethylene graft maleic anhydride (Shanghai Rizhisheng Company) as compatibilizer, n-butyl acrylate-glycidyl ester as toughening agent 2 parts by weight of copolymer (DuPont), 15 parts by weight of aluminum hypophosphite (purchasing Clariant Company) as flame retardant, 0.3 parts by weight of anti-UV agent (UV360), 0.15 parts by weight of antioxidant (1098), coupling Agent (KH570) 0.15 parts by weight, lubricant (silicone powder) 0.2 parts by weight.

[0058] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com