Polyropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of reducing mutual aggregation, rigid particle toughening effect is not obvious, etc., to achieve excellent notched impact strength, large shear force, production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

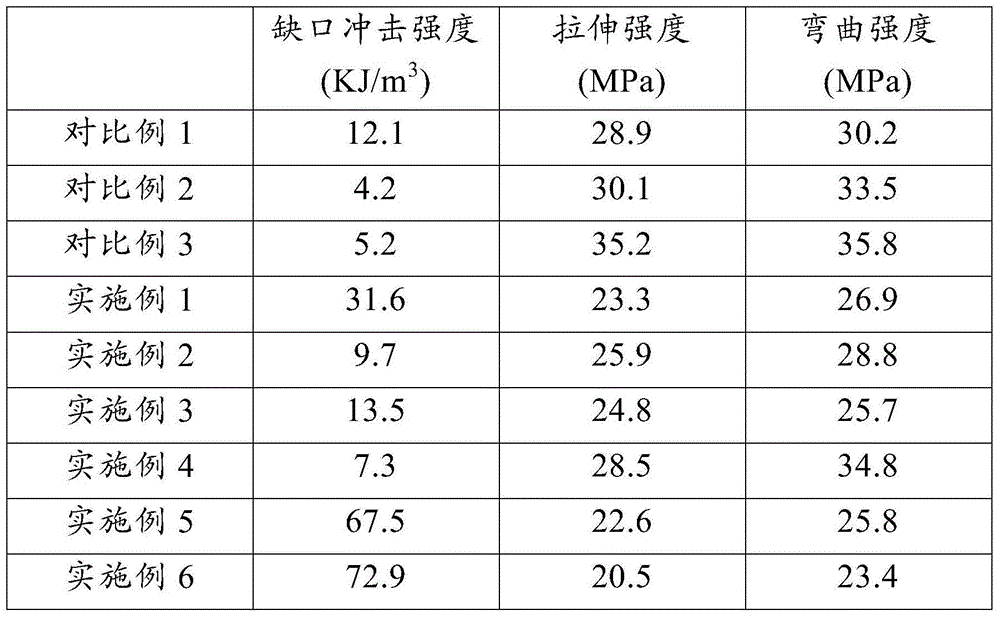

Examples

Embodiment 1

[0029] Inorganic filler CaCO 3 Dry in an oven at 150°C for 2 hours, weigh 65 parts of polypropylene, 15 parts of POE, and 20 parts of CaCO 3 , 0.2 parts of composite antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (abbreviated as 1010) and tris[2,4-di-tert-butylphenyl] Phosphite (referred to as 168) (weight ratio 1:1), 0.5 parts of processing aid calcium stearate and EBS (weight ratio 1:4) are mixed in a high-speed mixer and then added to a twin-screw extruder. 140~220°C (the temperature of each zone is 140°C, 180°C, 200°C, 220°C, 220°C, 220°C, 180°C, the same below, omitted) melt blending extrusion, cooling, pelletizing to obtain polypropylene composite material.

Embodiment 2

[0031] Inorganic filler CaCO 3 Dry in an oven at 150°C for 2 hours, weigh 70 parts of polypropylene, 10 parts of POE, 20 parts of CaCO 3 , 0.2 parts of antioxidant 1010 and bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite (referred to as 626) (weight ratio 1:1), 0.5 parts of processing aid calcium stearate and EBS (weight Ratio 1:4) Mixed uniformly in a high-speed mixer, then added to a twin-screw extruder, melted, blended, extruded, cooled, and pelletized at a temperature range of 140-220°C to obtain a polypropylene composite material.

Embodiment 3

[0033] Inorganic filler CaCO 3 Dry in an oven at 150°C for 2 hours, weigh 85 parts of polypropylene, 10 parts of POE, 5 parts of talc, 0.2 parts of antioxidants 1010 and 168 (weight ratio 1:1), 0.5 parts of processing aid stearic acid Calcium and EBS (weight ratio 1:4) are mixed evenly in a high-speed mixer, then added to a twin-screw extruder, melted, blended and extruded at a temperature range of 140-220 ° C, cooled, and pelletized to obtain a polypropylene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com