Wear-resistant flame-retardant conveying belt and preparation process thereof

A technology of conveyor belts and flame retardants, applied in the field of wear-resistant and flame-retardant conveyor belts and its preparation technology, can solve problems such as secondary disasters of life and property, corrosion of equipment and instruments, and obstruction of disaster relief work, and achieve mechanical strength and chemical stability Good performance, pollution reduction, long-lasting thermal stability and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

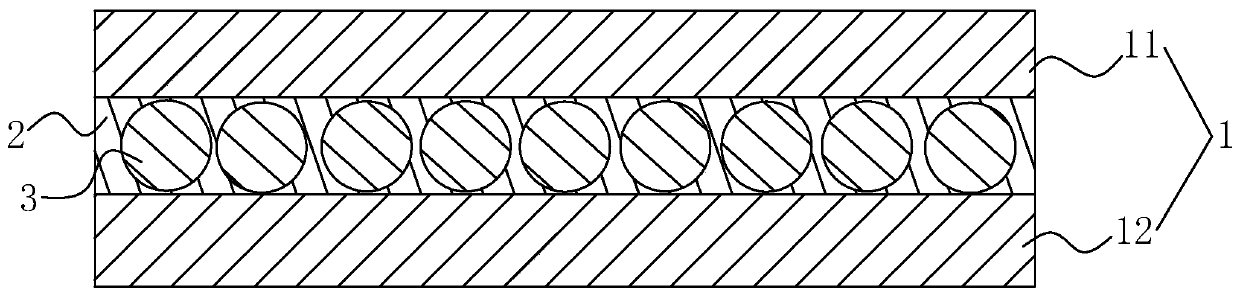

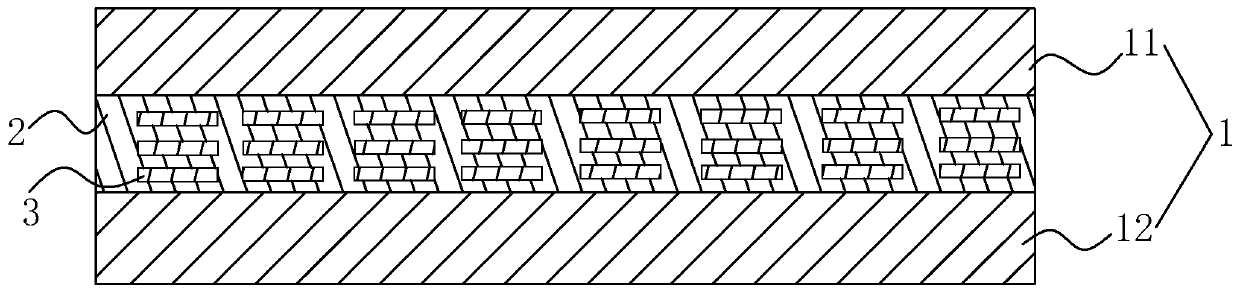

Image

Examples

preparation example 1-3

[0056] In the preparation example 1-3, the aramid 1313 fiber is sold by Hangzhou Jiulong Aramid Fiber Co., Ltd., the zinc stearate is selected from the PLB type zinc stearate sold by Guangzhou Jingyi New Material Co., Ltd., and the silicon dioxide is selected from Guangzhou Jingyi New Material Co., Ltd. Yixin Materials Co., Ltd. sells HP-220 type silica.

preparation example 1

[0057] Preparation Example 1: (1) According to the proportioning in Table 1, 5kg of aramid fiber 1313 fibers were surface treated with 1kg of coupling agent KH-570,

[0058] (2) Add 10kg of montmorillonite into 10kg of distilled water, stir at 1000r / min to make a suspension, let it stand for 20h, disperse 1kg of melamine phosphate in 20kg of distilled water, heat to 90°C, After stirring evenly under high pressure, add it into the montmorillonite suspension heated to 80°C, stir at 900r / min for 3h, cool, filter, dry, and pulverize;

[0059] (3) Heat 20kg of polypropylene resin to 165°C, add 1kg of zinc stearate, aramid 1313 fiber obtained in step (1), 1kg of silicon dioxide and the product of step (2) into the polypropylene emulsion, and mix well , extruded and granulated, and the extrusion temperature was 170°C.

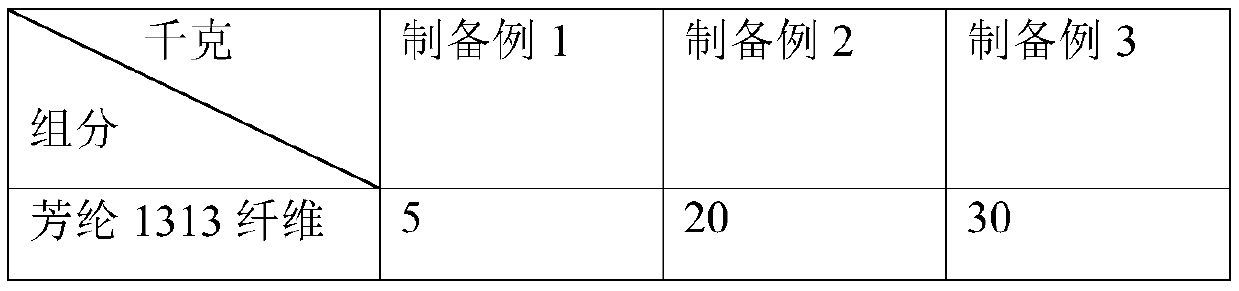

[0060] The raw material ratio of wear-resistant filler in the preparation example 1-3 of table 1

[0061]

[0062]

preparation example 2

[0063] Preparation Example 2: (1) According to the proportioning in Table 1, 20kg of aramid fiber 1313 fibers are surface treated with 3kg of coupling agent KH-570,

[0064] (2) Add 13kg of montmorillonite to 13kg of distilled water, stir at 1500r / min to make a suspension, let it stand for 22h, disperse 3kg of melamine phosphate in 27kg of distilled water, heat to 100°C, After stirring evenly under high pressure, add it into the montmorillonite suspension heated to 83°C, stir at 950r / min for 3.5h, cool, filter, dry, and pulverize;

[0065] (3) Heat 25kg of polypropylene resin to 170°C, add 3kg of zinc stearate, aramid 1313 fiber obtained in step (1), 3kg of silicon dioxide and the product of step (2) into the polypropylene emulsion, and mix well , extruded and granulated, and the extrusion temperature was 175°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com