Preparation method of silicon modified double-component waterborne polyurethane composite coating for automobile varnish

A water-based polyurethane and composite coating technology, applied in the field of coatings, can solve the problems of consuming curing agent active groups, high cost of nano-zinc oxide, affecting curing effect, etc., to improve adhesion and water resistance, conducive to large-scale application, Beneficial for uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

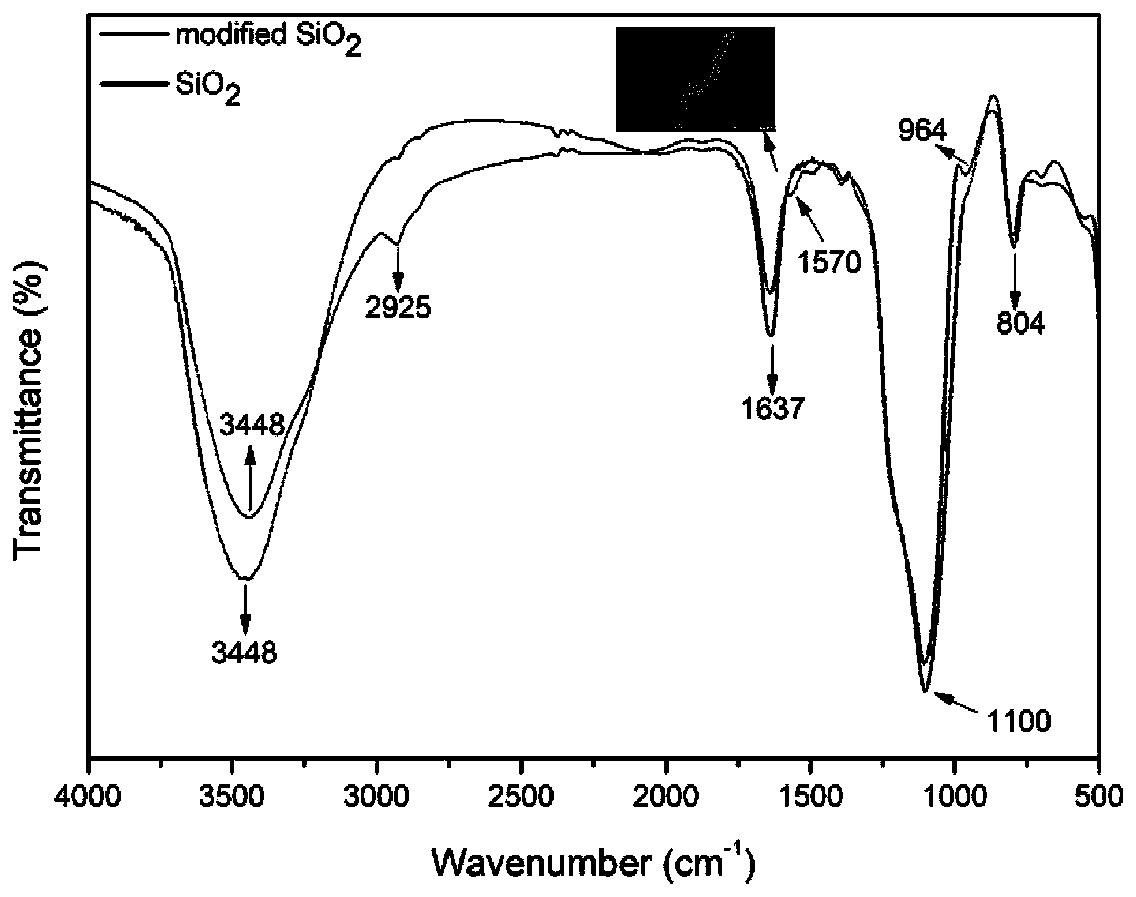

Method used

Image

Examples

Embodiment 1

[0045] 18 parts of methyl methacrylate, 10 parts of butyl acrylate, 10 parts of styrene, 4 parts of β-hydroxyethyl methacrylate, 1 part of acrylic acid, and emulsifier 1.3 parts of sodium lauryl sulfate, 0.7 parts of Tween 80 was added to the beaker, and then 20mL of distilled water was added, and magnetically stirred for 0.5-1h until it was completely emulsified. Add 0.13 parts of potassium persulfate, 0.05 parts of sodium bicarbonate and 10 mL of distilled water into a three-necked flask equipped with a stirring paddle and a condenser, heat and stir to 75 ° C under nitrogen gas atmosphere, then take 1 / 3 of the pre-emulsion, and use peristaltic The pump drips into the flask, and the dripping is completed within 1 to 1.5 hours, then the temperature is raised to 80°C and kept for 1 hour. Then add 0.25 parts of potassium persulfate at the same time, and drop the remaining 2 / 3 of the pre-emulsion into the flask through a peristaltic pump, drop it in 2-2.5 hours and keep it warm f...

Embodiment 2

[0047] 18 parts of methyl methacrylate, 10 parts of butyl acrylate, 10 parts of styrene, 1 part of acrylic acid, 4 parts of β-hydroxyethyl methacrylate, and 1.3 parts of emulsifier sodium lauryl sulfate, 0.7 parts of Tween 80 was added to the beaker, and then 20mL of distilled water was added, and magnetically stirred for 0.5-1h until it was completely emulsified. Add 0.13 parts of potassium persulfate, 0.05 parts of sodium bicarbonate and 10 mL of distilled water into a three-necked flask equipped with a stirring paddle and a condenser, heat and stir to 75 ° C under nitrogen gas atmosphere, then take 1 / 3 of the pre-emulsion, and use peristaltic The pump drips into the flask, and the dripping is completed within 1 to 1.5 hours, then the temperature is raised to 80°C and kept for 1 hour. Then add 0.25 parts of potassium persulfate at the same time, and drop 1.7 parts of self-made polysiloxane with double bonds and the remaining 2 / 3 pre-emulsion into the flask through a peristal...

Embodiment 3

[0049] 18 parts of methyl methacrylate, 10 parts of butyl acrylate, 10 parts of styrene, 1 part of acrylic acid, 4 parts of β-hydroxyethyl methacrylate and emulsifier 1.3 parts of sodium lauryl sulfate, 0.7 parts of Tween 80 Add it to a beaker, then add 20mL of distilled water, and stir magnetically for 0.5-1h until it is completely emulsified. Add 0.13 parts of potassium persulfate, 0.05 parts of sodium bicarbonate and 10 mL of distilled water into a three-necked flask equipped with a stirring paddle and a condenser, heat and stir to 75 ° C under nitrogen gas atmosphere, then take 1 / 3 of the pre-emulsion, and use peristaltic The pump drips into the flask, and the dripping is completed within 1 to 1.5 hours, then the temperature is raised to 80°C and kept for 1 hour. Then add 0.25 parts of potassium persulfate at the same time, drop 3 parts of self-made polysiloxane with double bonds and the remaining 2 / 3 pre-emulsion into the flask through a peristaltic pump, drop it in 2-2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com