Adhesive resin for continuous fiber reinforced plastic composite pipe and preparation method thereof

A technology of reinforced plastics and bonding resins, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of inability to quickly and continuously construct, unfavorable environmental protection, construction efficiency and environmental protection problems, etc., to achieve light weight, Improve the bonding effect and the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned adhesive resin for continuous fiber reinforced plastic composite pipes comprises the following steps: grafting the weighed polyolefin with silane, compatibilizer, polyolefin matrix resin, elastomer tackifying resin, processing anti-aging aid After being dried separately, it is pre-mixed by a high-speed mixer and then added to the twin-screw extruder; the reactive polyurethane is heated and then added to the twin-screw extruder by online metering and filling; it is extruded and bonded after twin-screw mixing Resin; after multi-stage air cooling, granulation and sealed packaging, the whole process is dried to prevent the entry of water vapor; the adhesive resin for continuous fiber reinforced plastic composite pipes is obtained.

[0033] As a further embodiment, the temperature in the twin-screw extruder is 200° C., the screw speed is 300 rpm, the feeding is 7 Hz, and the twin-screw length-to-diameter ratio L / D is 38:1.

Embodiment 1

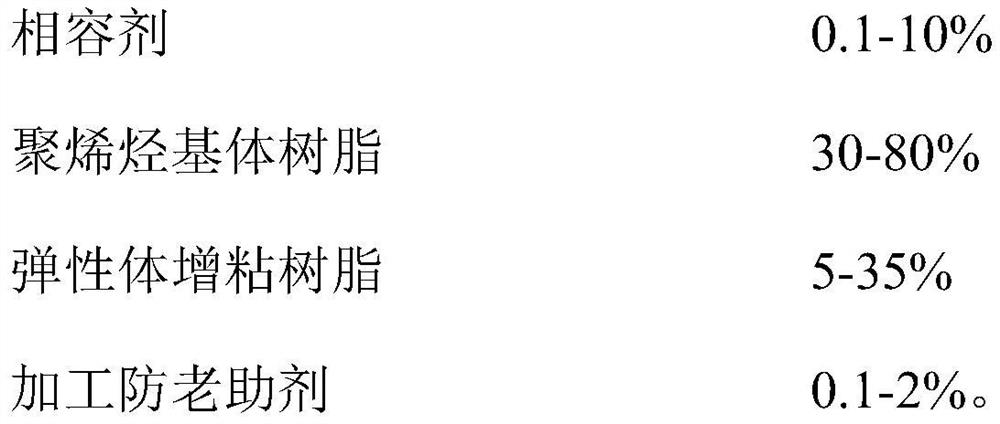

[0036] An adhesive resin for continuous fiber-reinforced plastic composite pipes, which is prepared from the following components in percentage by weight:

[0037]

[0038]

[0039] Among them, polyethylene grafted silane is High-density polyethylene grafted silane (melt flow rate MI: 2.0g / 10min, melting point Tm: 134°C, grafting rate GR: 0.8%) 100%;

[0040] Reactive polyurethane is Reactive polyurethane PUR 9350;

[0041] compatibilizer is Ethylene-butyl acrylate copolymer EBA 3427;

[0042] Polyethylene matrix resin is 60% High-density polyethylene DGDA-2399, 40% High-density polyethylene TR480;

[0043] Elastomeric tackifying resins are Polyolefin elastomer POE 8200;

[0044] Processing anti-aging additives are Antioxidant B215.

Embodiment 2

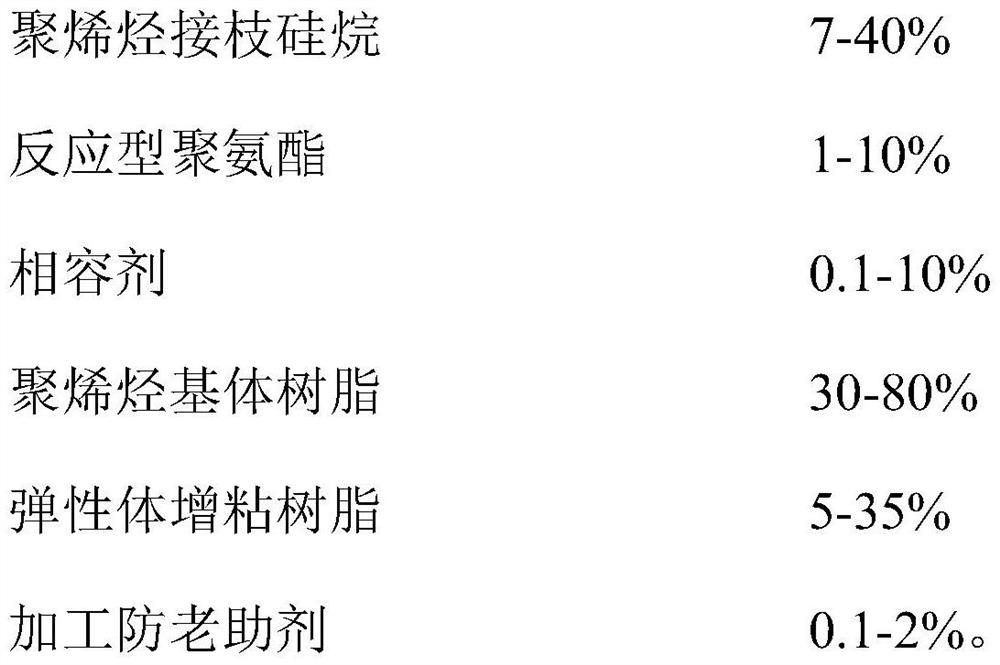

[0046] An adhesive resin for continuous fiber-reinforced plastic composite pipes, which is prepared from the following components in percentage by weight:

[0047]

[0048] Among them, polyethylene grafted silane is High-density polyethylene grafted silane (MI: 2.0g / 10min, Tm: 134°C, grafting rate GR: 0.8%);

[0049] Reactive polyurethane is Reactive polyurethane PUR 9350;

[0050] compatibilizer is Ethylene-butyl acrylate copolymer grafted maleic acid EBA-g-MAH 3427 (MI: 2.1g / 10min, Tm: 91°C, grafting rate GR: 0.7%);

[0051] Polyethylene matrix resin is 50% High-density polyethylene DGDA-2399, 50% High-density polyethylene TR480;

[0052] Elastomeric tackifying resins are Polyolefin elastomer POE 8200;

[0053] Processing anti-aging additives are Antioxidant B215.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com