A kind of polyamide composition and preparation method thereof

A polyamide composition and drying technology, applied in the field of polyamide composition and its preparation, can solve the problems that the rigidity and toughness of the material cannot be taken into account at the same time, the tensile strength and the bending strength are decreased, etc. The effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

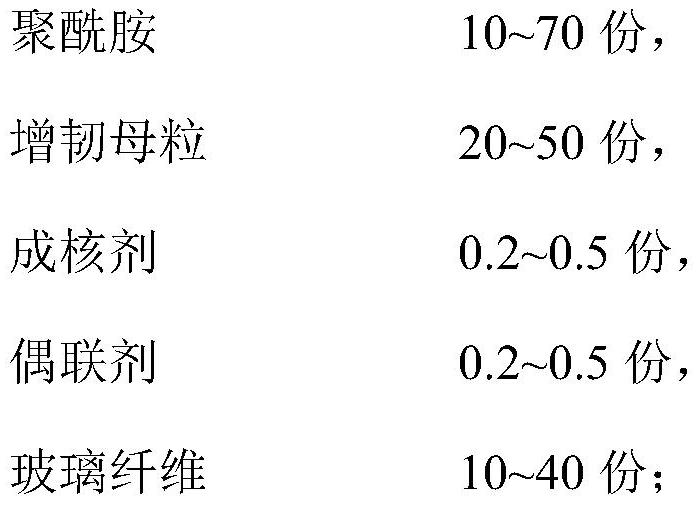

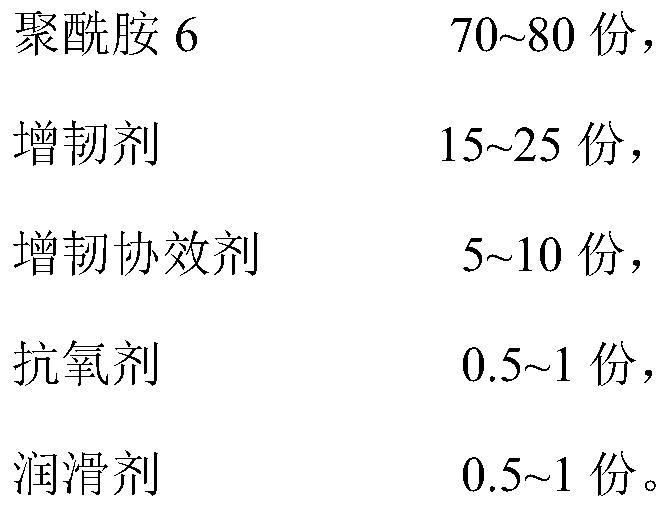

Method used

Image

Examples

Embodiment 1

[0027] According to parts by weight, dry 70 parts of PA6, 25 parts of maleic anhydride grafted polyolefin elastomer, 5 parts of ethylene-acrylic acid ester-glycidyl methacrylate copolymer, 1 part of pentaerythritol stearate, 0.5 part of anti- Oxygen 1098 and 0.5 parts of antioxidant PEP-36 were added to a high-speed mixer and mixed at high speed for 8 minutes, then added to a twin-screw extruder (temperature 210°C, screw speed 350 rpm, screw length-to-diameter ratio 36:1 ) in the process of melt blending, extrusion granulation, homogenization and drying to obtain toughened masterbatch;

[0028] Add 70 parts of PA66, 0.2 part of nano-montmorillonite, 0.2 part of silane coupling agent and 20 parts of toughening masterbatch into the high-speed mixer according to parts by weight and mix at high speed for 10 minutes, then add it to the twin-screw extruder from the main feeding hopper, Then add 10 parts of dry glass fiber from the side feeding hopper into a twin-screw extruder (temp...

Embodiment 2

[0030] According to parts by weight, dry 72 parts of PA6, 20 parts of maleic anhydride grafted polyolefin elastomer, 8 parts of ethylene-acrylic acid ester-glycidyl methacrylate copolymer, 0.8 part of ethylene bis stearamide, 0.4 part Antioxidant 1098 and 0.3 parts of antioxidant PEP-36 were added to the high-speed mixer after high-speed mixing for 8 minutes, and then added to the twin-screw extruder (temperature 280 ° C, screw speed is 550 rpm, and the screw length-to-diameter ratio is 44: 1) performing melt blending, extrusion granulation, homogenization and drying to obtain toughened masterbatch;

[0031] According to parts by weight, 50 parts of PA6, 0.5 part of nano talcum powder, 0.5 part of silane coupling agent and 30 parts of toughening masterbatch are added to the high-speed mixer and mixed at high speed for 10 minutes, then added to the twin-screw extruder from the main feeding hopper, and then Add 20 parts of dry glass fiber from the side feeding hopper into a twin...

Embodiment 3

[0033] According to parts by weight, dry 75 parts of PA6, 20 parts of maleic anhydride grafted polyolefin elastomer, 5 parts of ethylene-acrylic acid ester-glycidyl methacrylate copolymer, 0.6 part of modified polyethylene wax, 0.3 part of anti- Oxygen 1098 and 0.2 parts of antioxidant PEP-36 were added to a high-speed mixer and mixed at high speed for 8 minutes, then added to a twin-screw extruder (temperature 250 ° C, screw speed 400 rpm, screw length-to-diameter ratio 41:1 ) in the process of melt blending, extrusion granulation, homogenization and drying to obtain toughened masterbatch;

[0034] According to parts by weight, 30 parts of PA6, 0.3 part of calcium montanate, 0.5 part of silane coupling agent and 40 parts of toughening masterbatch are added to the high-speed mixer after high-speed mixing for 10 minutes, then added to the twin-screw extruder from the main feeding hopper, and then Add 30 parts of dry glass fiber from the side feeding hopper into a twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com