A kind of high-performance medium manganese trip steel and the method for low-temperature processing thereof

A processing and high-performance technology, applied in the field of ultra-high-strength steel, can solve the problems of low austenite content and stability, C/Mn can not be distributed, and reduce the surface quality of stamping parts, etc., to achieve excellent mechanical properties, Effect of low molding temperature and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A low-temperature forming method of high-performance medium-manganese TRIP steel adopts low-temperature forming process (two-phase zone rolling+warm punching) and Q&P treatment process for medium-manganese steel, and its implementation steps are as follows:

[0046] S1: rolling in two-phase area

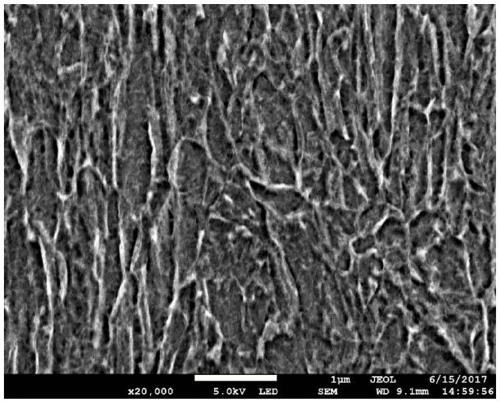

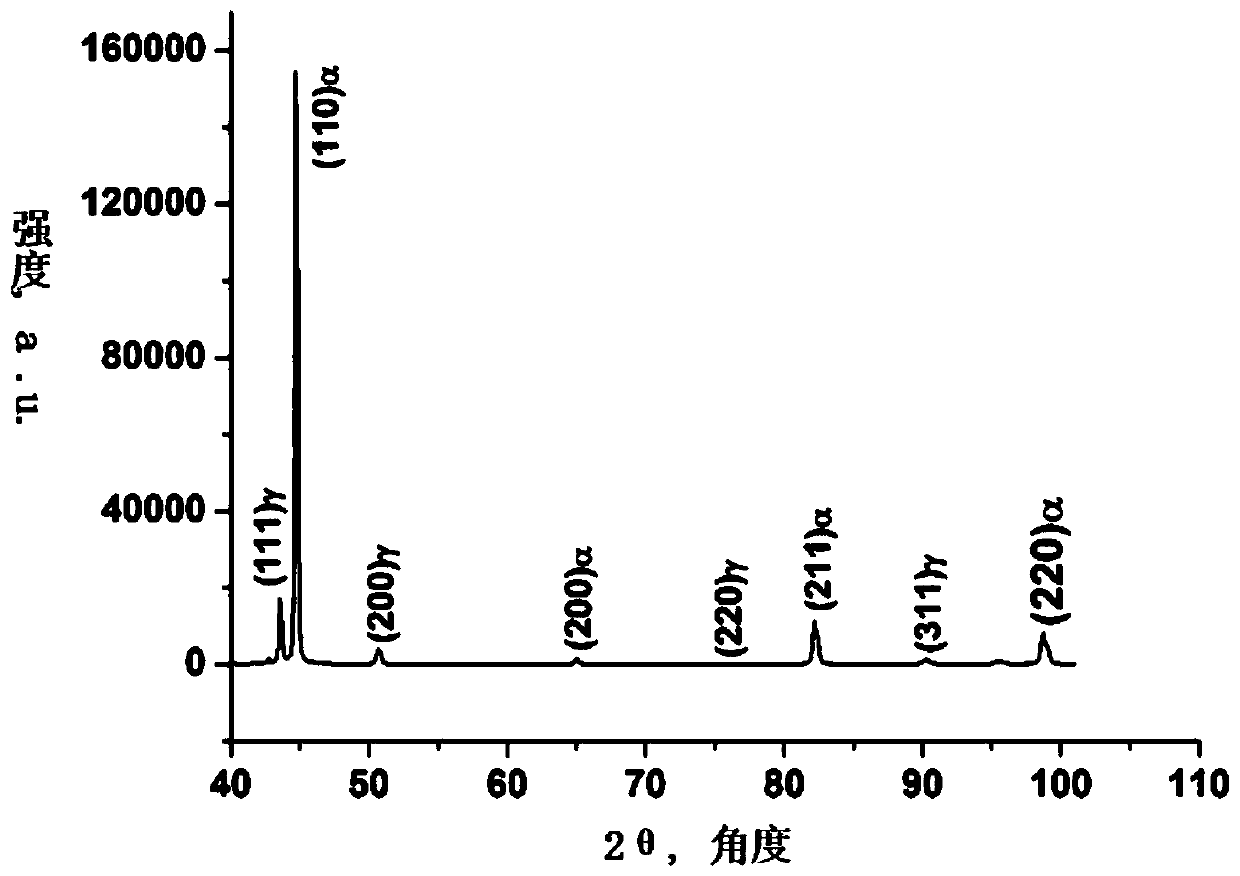

[0047] After heating the ingot of medium manganese steel to 700°C and keeping it warm for 1 hour, roll it 9 times on a two-roller hot rolling mill. The rolling temperature is controlled at 600-700°C. Return to the furnace at 800°C and reheat for 5 minutes to obtain a rolled plate with a thickness of 1.5-2.5mm, with a total deformation of 95-97%, and then air-cool to room temperature to obtain a nano / ultra-fine two-phase region-rolled medium manganese TRIP steel plate.

[0048] The composition of the medium manganese steel is: C is 0.2wt.%, Si is 0.50wt.%, Mn is 7.00wt.%, Al is 1.50wt.%, N is 0.014wt.%, Nb is 0.06wt.%. , Mo is 0.25wt.%, and the balance is Fe and unavoidable im...

Embodiment 2

[0056] A high-performance medium manganese TRIP steel, its chemical composition and content are: C is 0.20wt.%, Si is 0.05wt.%, Mn is 5.59wt.%, Al is 1.22wt.%, N is 0.014wt. %, Nb is 0.06wt.%, Mo is 0.22wt.%, and the balance is Fe and unavoidable impurities.

[0057] The above-mentioned low-temperature processing and forming method of high-performance medium manganese TRIP steel comprises the following steps:

[0058] S1: rolling in two-phase area

[0059] After heating the cut medium-manganese steel square ingot to 800°C and keeping it warm for 1 hour, it is quickly transferred to a two-roll hot rolling mill for 8 passes of hot rolling. The rolling temperature is controlled between 600 and 700°C. After the first pass of rolling, return to the furnace at 800°C and reheat for 5 minutes, the total deformation is 97%, rolling to obtain a 1.5mm thick rolled plate, and then air-cooled to room temperature to obtain nano / ultra-fine two-phase rolled medium manganese TRIP steel plate...

Embodiment 3

[0069] A kind of high-performance medium manganese TRIP steel, its composition is the same as embodiment 2.

[0070] A low-temperature forming method of high-performance medium manganese TRIP steel, the same as embodiment 2, the difference is:

[0071] In S2 in Example 1, cut the medium-manganese TRIP steel plate rolled in the nano / ultra-fine two-phase region into a set size, put it in a heating furnace, heat it to 800 ° C, keep it for 8 minutes, and heat up the heat treatment furnace The speed is 8°C / s, and then it is quickly transferred to the stamping platform, which takes 5s, and the temperature drops to 700°C, then it is quickly stamped and formed, and the pressure is maintained for 20s, then the stamped part is removed, cooled to 200°C with the mold, and then quickly transferred to In the heating furnace, the temperature is 450°C, the temperature is kept for 10 minutes, and the air is cooled to room temperature to obtain a U-shaped high-performance medium manganese TRIP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com