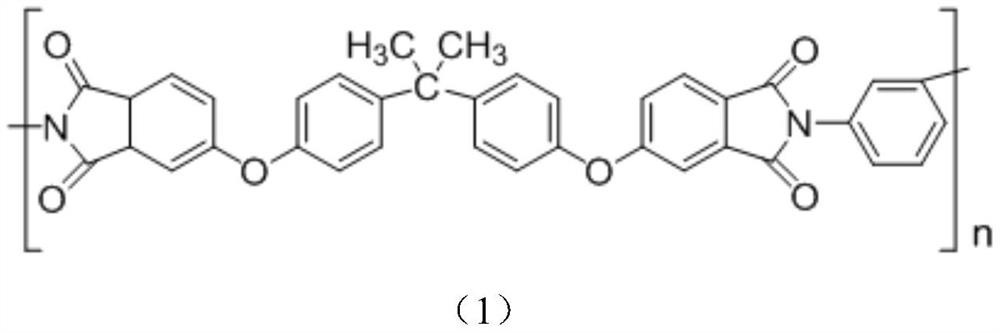

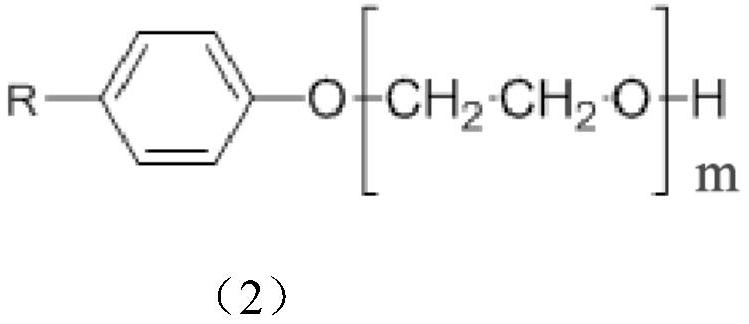

A polyetherimide resin-based carbon fiber suspension sizing agent and preparation method thereof

A technology of polyetherimide resin and suspension, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of poor safety and environmental protection, product stability, etc., and achieve temperature resistance and interface Excellent binding ability, easy preparation, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

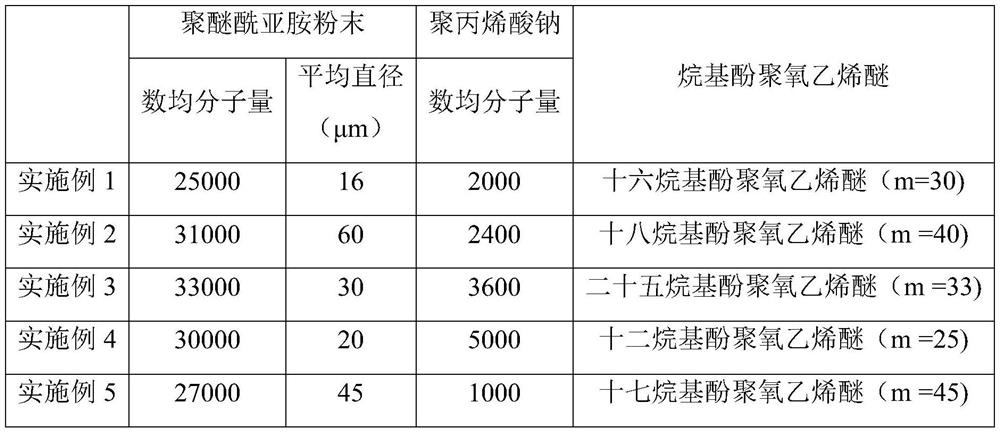

[0038] Put quantitative polyetherimide resin powder and sodium polyacrylate into stirring tank A in turn, and gradually add quantitative deionized water dropwise. When the amount of water added reaches 25wt% of the total feeding amount, start the mechanical stirring, and continuously stir at a certain speed. And continue to add the remaining amount of water, stir for a certain time to obtain a uniform white emulsion, discharge and transfer to the stirring kettle B equipped with a high-speed emulsifier, add a quantitative amount of alkylphenol polyoxyethylene ether, open the high-speed emulsifier, Continue stirring at a fixed rotational speed, and discharge to obtain a milky white suspension sizing agent.

[0039] The polyetherimide powder was from General Electric Company of the United States, and the sodium polyacrylate and alkylphenol polyoxyethylene ether were from BASF Corporation. The solid components of the suspension sizing agent prepared in Examples 1-8 are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com