Method for preparing positive electrode material of lithium sulfur battery

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problem of capacity reduction, achieve the effect of improving electronic conductivity and lithium ion mobility, and increasing reversible specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

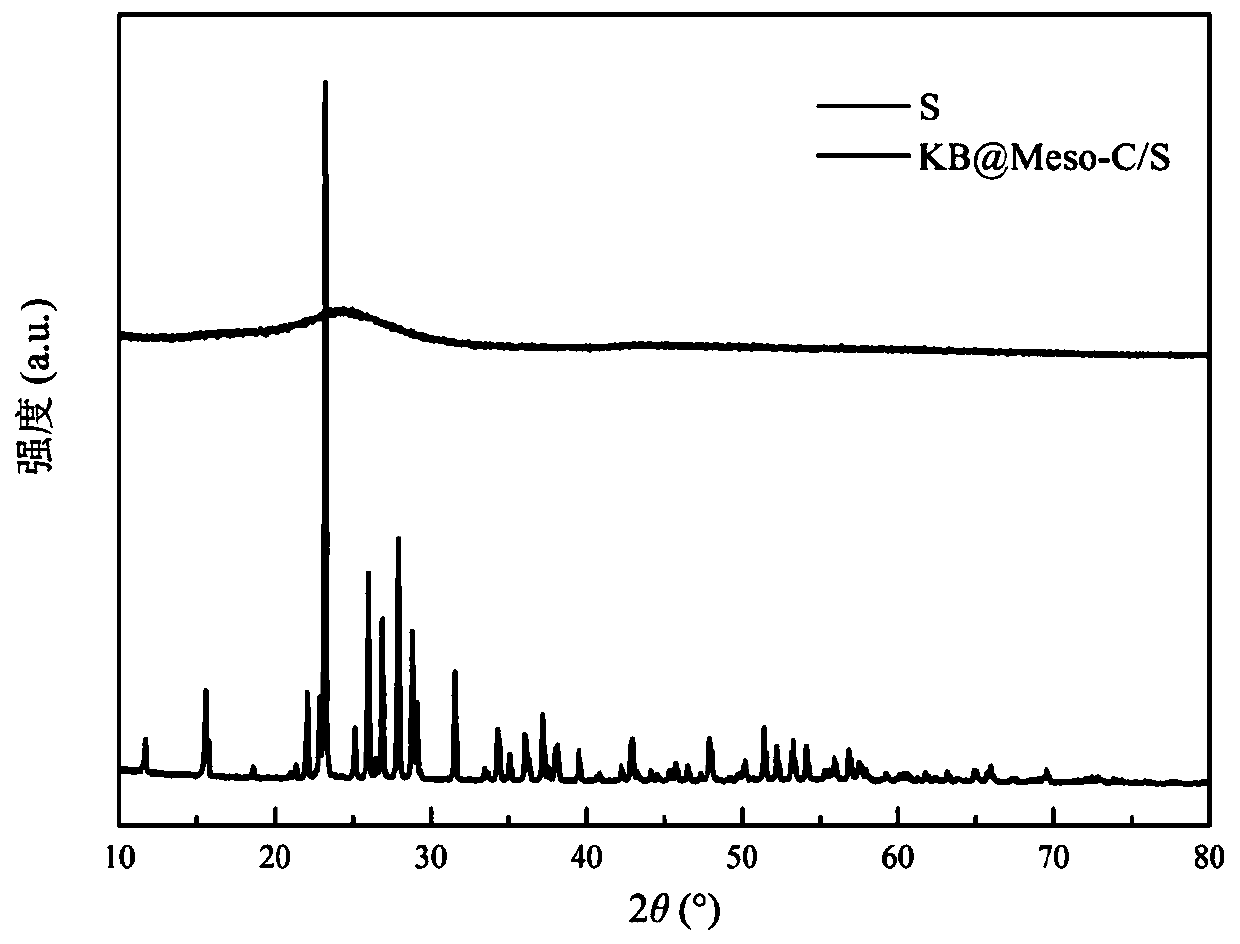

Image

Examples

Embodiment 1

[0031] A preparation method of a lithium-sulfur battery cathode material, the specific preparation process is as follows:

[0032] In the first step, 1.78g Zn(NO 3 ) 2 ·6H 2 O, 0.33g C 8 h 6 o 4 , 0.1g KB and 10mg polyethylene glycol were added to 60mL of DMF, the ultrasonic power was set to 60KHz, and a uniformly dispersed mixed solution was formed after ultrasonic stirring for 30min;

[0033] In the second step, add the mixed solution prepared in the first step into the hydrothermal reaction kettle and place it in an oven, raise the temperature to 135°C at a heating rate of 5°C / min and keep it warm for 24 hours, then cool it down to room temperature naturally, wash and filter the precipitate with DMF After three times, it was placed in a vacuum oven at 150°C for 24 hours to obtain the precursor compound KB@MOF-5;

[0034] In the third step, the precursor compound KB@MOF-5 obtained in the second step is placed in a tube furnace with a nitrogen atmosphere, the nitrogen g...

Embodiment 2

[0037] A preparation method of a lithium-sulfur battery cathode material, the specific preparation process is as follows:

[0038] In the first step, 1.19g Zn(NO 3 ) 2 ·6H 2 O, 0.33g C 8 h 6 o 4 , 0.07g KB and 6mg polyacrylamide were added to 50mL of DMF, the ultrasonic power was set to 50KHz, and a uniformly dispersed mixed solution was formed after ultrasonic stirring for 35min;

[0039] In the second step, add the mixed liquid prepared in the first step into the hydrothermal reaction kettle and place it in an oven, raise the temperature to 110°C at a heating rate of 3°C / min and keep it for 24 hours, then cool it down to room temperature naturally, wash and filter the precipitate with DMF After three times, it was placed in a vacuum oven at 155°C for 16 hours to obtain the precursor complex KB@MOF-5;

[0040] In the third step, the precursor compound KB@MOF-5 obtained in the second step is placed in a tube furnace with a nitrogen atmosphere, the nitrogen gas flow rate ...

Embodiment 3

[0043] A preparation method of a lithium-sulfur battery cathode material, the specific preparation process is as follows:

[0044] In the first step, 1.49g Zn(NO 3 ) 2 ·6H 2 O, 0.33g C 8 h 6 o 4 , 0.08g KB and 8mg hydroxyethyl cellulose were added to 60mL of DMF, the ultrasonic power was set to 70KHz, and a uniformly dispersed mixed solution was formed after ultrasonic stirring for 40min;

[0045] In the second step, add the mixed solution prepared in the first step into the hydrothermal reaction kettle and place it in an oven, raise the temperature to 140°C at a heating rate of 5°C / min and keep it for 24 hours, then cool it down to room temperature naturally, wash and filter the precipitate with DMF After three times, it was placed in a vacuum oven at 160°C for 12 hours to obtain the precursor complex KB@MOF-5;

[0046] In the third step, the precursor compound KB@MOF-5 obtained in the second step is placed in a tube furnace with a nitrogen atmosphere, the nitrogen gas fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com