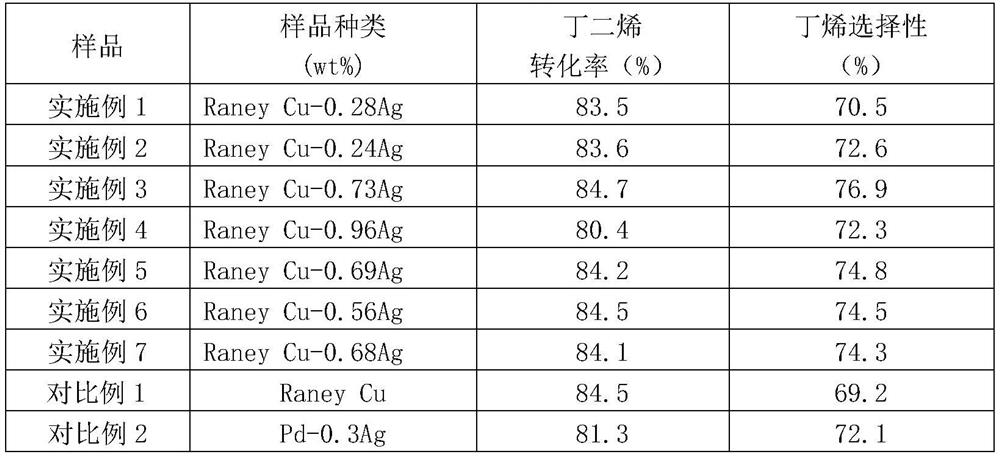

A kind of method that adopts silver carbonized Raney copper catalyst to carry out selective hydrogenation of C4 raffinate to prepare 1-butene

A carbonized Raney copper and catalyst technology, which is applied in the direction of carbon compound catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of uncontrollable doping amount of silver additives, achieve high utilization rate and reduce costs , the effect of high airspeed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass and stirred evenly.

[0058] (2) Take by weighing 50g step (1) prepared epoxy system and 150g copper-aluminum alloy powder and fully stir and mix, Cu content is 50% (weight) in the copper-aluminum alloy, and aluminum content 50% (weight), take appropriate amount Put the mixture into a cylindrical mold, mold it with a flat vulcanizer at a temperature of 120°C and a pressure of 7MPa for 30mins, and use a flat vulcanizer at a temperature of 150°C and a pressure of 7MPa for 90mins, and take it out after cooling to obtain a 2.0mm× About 3.0mm cylindrical catalyst precursor;

[0059] (3) Measure 100ml of catalyst precursor, put it into a tube-type high-temperature electric furn...

Embodiment 2

[0064] (1) Fully mix powdered phenolic resin and curing agent hexamethylenetetramine with a high-speed mixer, the weight ratio of hexamethylenetetramine to phenolic resin is 12 / 100; mix 100 grams of mixture with 300 grams of copper aluminum alloy The powder is fully mixed with a high-speed mixer, and the Cu content is 50% (weight) in the copper-aluminum alloy, and the aluminum content is 50% (weight);

[0065] (2) Heat up the tablet press to 90°C, put the above materials into the mold and press on the tablet press to form a sheet with a thickness of 2mm; raise the temperature of the tablet press to 150°C, and mold the formed sheet Put it into the mold and solidify under the pressure of 5MPa on the tablet press for 10min; cut the cured 2mm thick sheet into small rectangular particles of 3-5mm;

[0066] (3) Measure 100mL of small particles and carbonize them in a tube-type high-temperature electric furnace with a heating rate of 10°C / min and a furnace temperature of 650°C for 3 ...

Embodiment 3

[0071] (1) Fully mix powdered phenolic resin and curing agent hexamethylenetetramine with a high-speed mixer, the weight ratio of hexamethylenetetramine to phenolic resin is 12 / 100; mix 150 grams of mixture with 300 grams of copper aluminum alloy The powder is fully mixed with a high-speed mixer, and the Cu content is 50% (weight) in the copper-aluminum alloy, and the aluminum content is 50% (weight);

[0072] (2) Heat up the tablet press to 90°C, put the above materials into the mold and press on the tablet press to form a sheet with a thickness of 2mm; raise the temperature of the tablet press to 150°C, and mold the formed sheet Put it into the mold and solidify under the pressure of 5MPa on the tablet press for 10min; cut the cured 2mm thick sheet into small rectangular particles of 3-5mm;

[0073] (3) Measure 100mL of small particles and carbonize them in a tube-type high-temperature electric furnace with a heating rate of 10°C / min and a furnace temperature of 650°C for 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com