Functional pyrophyllite powder and application of functional pyrophyllite powder in reinforced and toughened PC-ABS alloy

A technology of pyrophyllite powder and functionalization, applied in the field of plastic processing, can solve the problems of low reliability, prone to pinholes, pollution of the environment, etc., and achieve the effects of good flame retardancy, high tensile strength, and good electroplating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of production technology of toughening reinforced PC-ABS alloy, comprises the following steps:

[0054] (1) 60 parts by weight of PC, 35 parts by weight of ABS, 10 parts by weight of AS, 0.15 parts by weight of main antioxidant, 0.15 parts by weight of auxiliary antioxidant, 0.3 parts by weight of calcium stearate, 0.2 parts by weight of pentaerythritol stearate 2 parts by weight, 2 parts by weight of N-phenylmaleimide, 1.5 parts by weight of 2-methylstyrene, and 2.5 parts by weight of compatibilizer are placed in a mixer, and are mixed for 15min at 600r / min with a rotating speed to obtain a mixed material;

[0055] (2) Put the mixed material into the twin-screw extruder. The temperature distribution of the extruder is as follows: from the feed section to the machine head: 235°C, 255°C, 260°C, 260°C, 255°C, 250°C ℃, 250℃, 250℃, 250℃, die head: 260℃, control the screw speed at 240r / min, melt extrusion, water cooling, pelletizing, and dry the pellets in a blast dry...

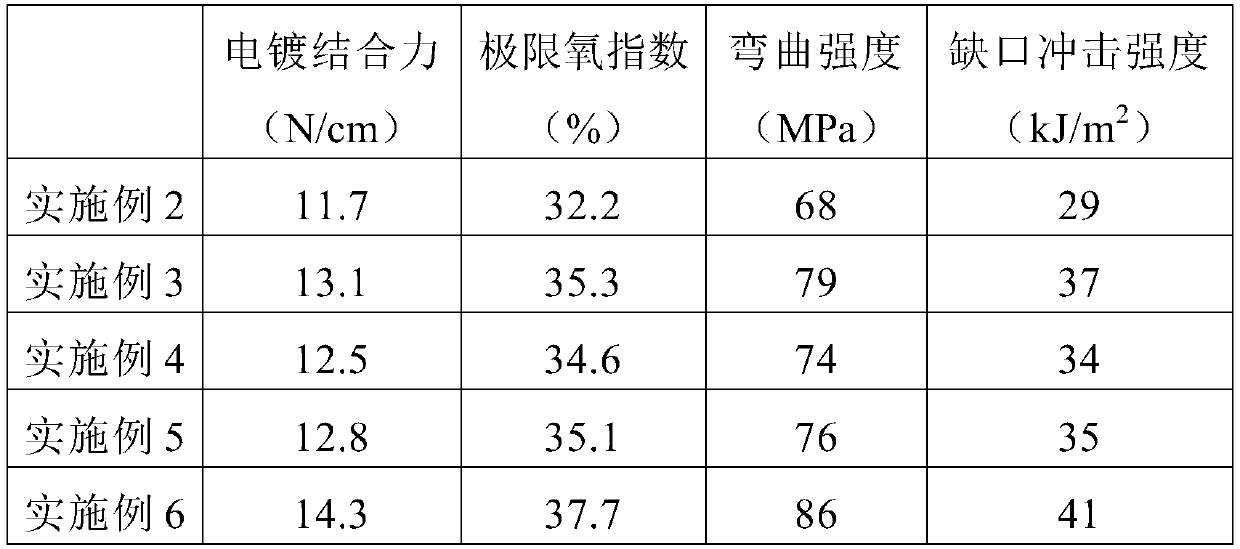

Embodiment 2

[0060] A kind of production technology of toughening reinforced PC-ABS alloy, comprises the following steps:

[0061] (1) 60 parts by weight of PC, 35 parts by weight of ABS, 10 parts by weight of AS, 0.15 parts by weight of main antioxidant, 0.15 parts by weight of auxiliary antioxidant, 7 parts by weight of pyrophyllite powder, 0.3 parts by weight of calcium stearate, 0.2 parts by weight of pentaerythritol stearate, 1.6 parts by weight of flame retardant, 2 parts by weight of N-phenylmaleimide, 1.5 parts by weight of 2-methylstyrene, and 2.5 parts by weight of compatibilizer are placed in the mixer , mixing for 15min at a speed of 600r / min to obtain a mixed material;

[0062] (2) Put the mixed material into the twin-screw extruder. The temperature distribution of the extruder is as follows: from the feed section to the machine head: 235°C, 255°C, 260°C, 260°C, 255°C, 250°C ℃, 250℃, 250℃, 250℃, die head: 260℃, control the screw speed at 240r / min, melt extrusion, water coolin...

Embodiment 3

[0068] A kind of production technology of toughening reinforced PC-ABS alloy, comprises the following steps:

[0069] (1) 60 parts by weight of PC, 35 parts by weight of ABS, 10 parts by weight of AS, 0.15 parts by weight of primary antioxidant, 0.15 parts by weight of auxiliary antioxidant, 7 parts by weight of functionalized pyrophyllite powder, 0.3 parts by weight of calcium stearate Parts, 0.2 parts by weight of pentaerythritol stearate, 1.6 parts by weight of flame retardant, 2 parts by weight of N-phenylmaleimide, 1.5 parts by weight of 2-methylstyrene, 2.5 parts by weight of compatibilizer are placed in mixing In the container, the mixing speed was 600r / min for 15min to obtain the mixed material;

[0070] (2) Put the mixed material into the twin-screw extruder. The temperature distribution of the extruder is as follows: from the feed section to the machine head: 235°C, 255°C, 260°C, 260°C, 255°C, 250°C ℃, 250℃, 250℃, 250℃, die head: 260℃, control the screw speed at 240...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com