A kind of denitrification functional packing and its preparation and application

A functional filler, denitrification technology, applied in chemical instruments and methods, granular microbial carrier treatment, water/sludge/sewage treatment, etc. growth and other problems, to avoid sludge bulking, reduce dosing, and produce less sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

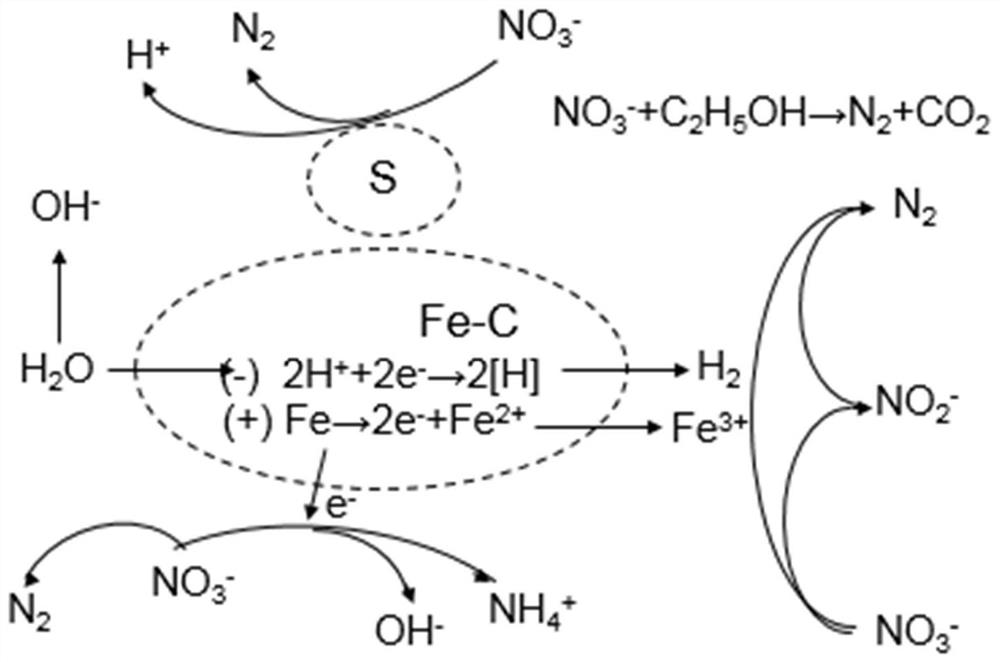

AI Technical Summary

Problems solved by technology

Method used

Image

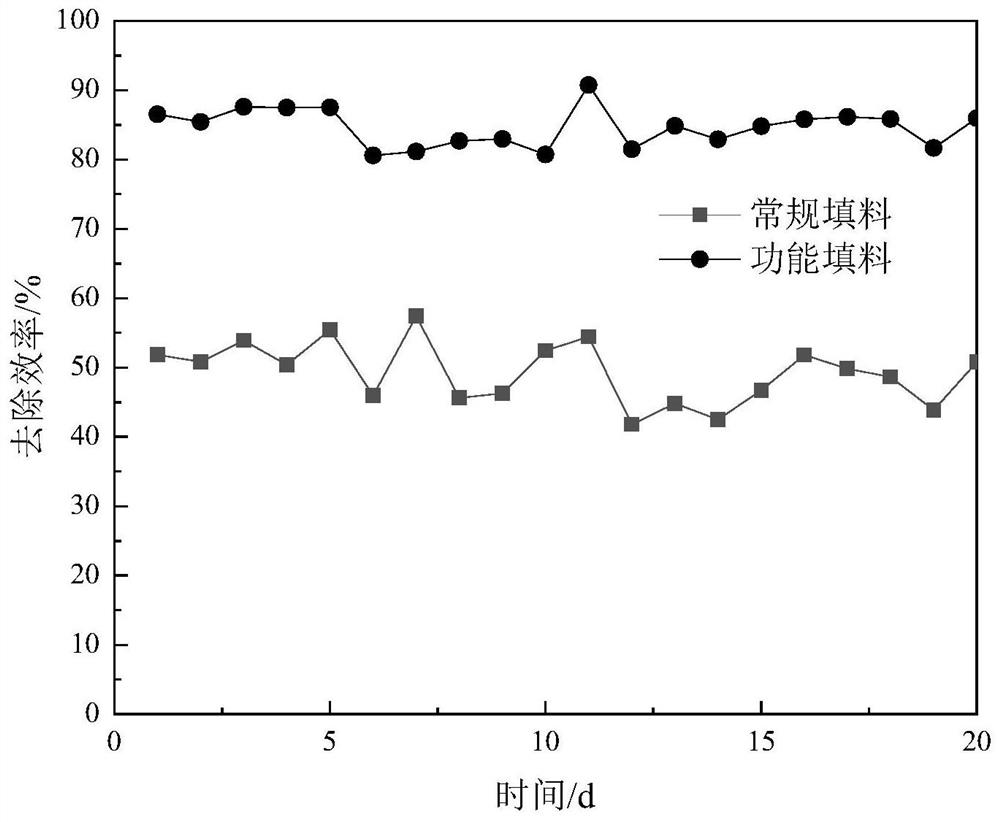

Examples

Embodiment 1

[0044] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0045] 1) Raw material selection: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the particle size of sulfur particles is 0.5-1mm; the copper powder is 200 mesh;

[0046] 2) Preparation of nitrogen-removing functional filler: Blend and mix each component according to a certain mass ratio, including 30% reduced iron powder, 10% activated carbon, 5% copper powder, 30% sulfur, 15% calcium sulfate, and 5% ammonium bicarbonate , NaOH 5%. Slowly add 15% water of the mass sum of each component to form a viscous mixed material, fill the mixed material into a spherical mold with a particle size of 9mm, and dry the material in a vacuum oven at 60°C for 8 hours. Then take it out from the mold, and dry it in a vacuum drying oven at 100°C to make holes, and ...

Embodiment 2

[0050] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0051] 1) Raw material selection: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the sulfur particle size is 0.5-1mm; the copper powder is 200 mesh; the magnesium powder is 200 mesh;

[0052] 2) Preparation of nitrogen-removing functional filler: Blend and mix each component according to a certain mass ratio, including 30% reduced iron powder, 10% activated carbon, 3% copper powder, 2% magnesium powder, 30% sulfur, and 15% sodium alginate , Ammonium Bicarbonate 5%, Sodium Dihydrogen Phosphate 5%. Slowly add 15% water of the mass sum of each component to form a viscous shape, fill the mixed material into a spherical mold with a particle size of 9mm, dry the material in a vacuum oven at 60°C for 8 hours, and then remove it from the mold Take it ou...

Embodiment 3

[0056] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0057] 1) Selection of raw materials: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the particle size of sulfur particles is 0.5-1mm; the manganese powder is 200 mesh; the tin powder is 200 mesh;

[0058] 2) Preparation of nitrogen-removing functional filler: mix and mix the components according to a certain mass ratio, including 25% reduced iron powder, 8% activated carbon, 3% manganese powder, 2% tin powder, 38% sulfur, 18% gum arabic, Ammonium oxalate 3%, calcium carbonate 3%. Slowly add 15% water of the mass sum of each component to form a viscous shape, fill the mixed material into a spherical mold with a particle size of 9mm, dry the material in a vacuum oven at 60°C for 8 hours, and then remove it from the mold Take it out and dry it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com