Magnetic fluid impulse type minipump

A propulsion, micro-pump technology, used in liquid variable capacity machinery, pumps, machines/engines, etc., can solve the problems of small flow, inability to work continuously, and high driving voltage, to improve output pressure, increase pipeline length, chemical Stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

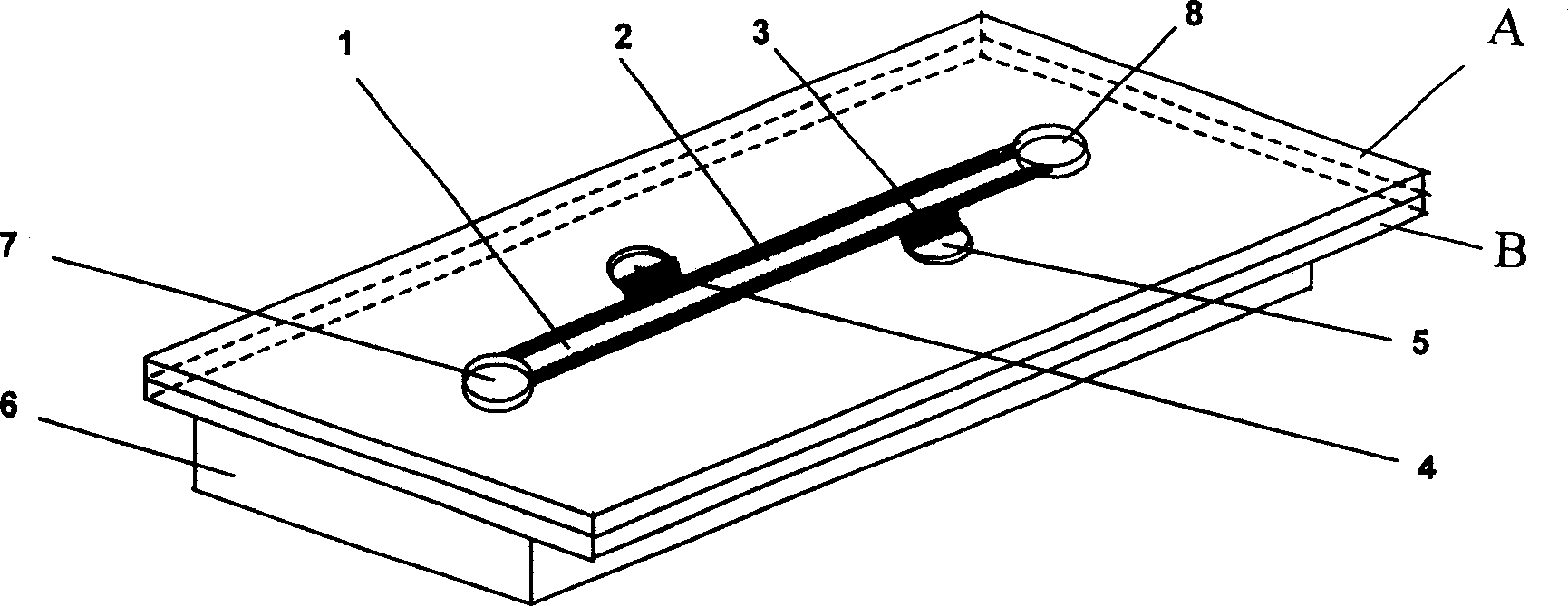

[0021] Such as figure 1 , figure 2 As shown, the present invention includes: a first base material A with two electrodes and two pipe inlets and outlets respectively, micro pipes are etched, and electrodes 2, 3 are sputtered on the two side walls of the whole micro pipes. The second base material B, the permanent magnet 6; the liquid storage tanks 7, 8 and the two electrode lead-out points 4, 5 at the two ends of the pipeline on the upper surface of the second base material B are respectively connected with the two electrodes on the first base material A The electrode and the inlet and outlet of the two pipes are aligned and bonded together, and a permanent magnet 6 is installed on the entire lower surface of the second base material B.

[0022] Such as figure 1 As shown, the micropipe whose cross-sectional shape is rectangular is a straight micropipe 1 .

[0023] Such as figure 2 , image 3 , Figure 4 Shown, said cross-sectional shape is that the micropipeline of rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com