Low-temperature curing silver/silver chloride slurry for flexible bioelectrode and preparation method thereof

A bio-electrode, silver chloride technology, used in applications, diagnostic recording/measurement, sensors, etc., to achieve the effect of improving production efficiency, strong anti-interference ability, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

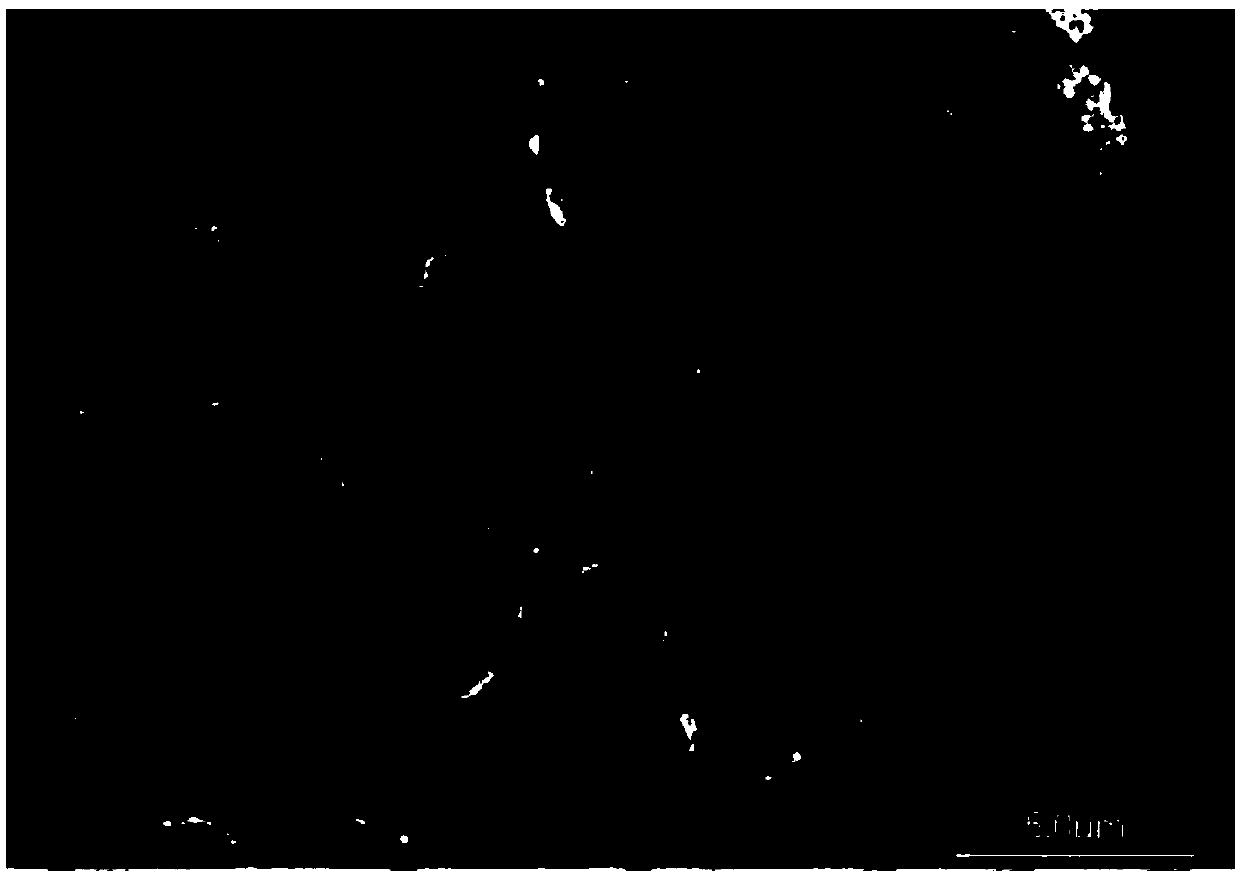

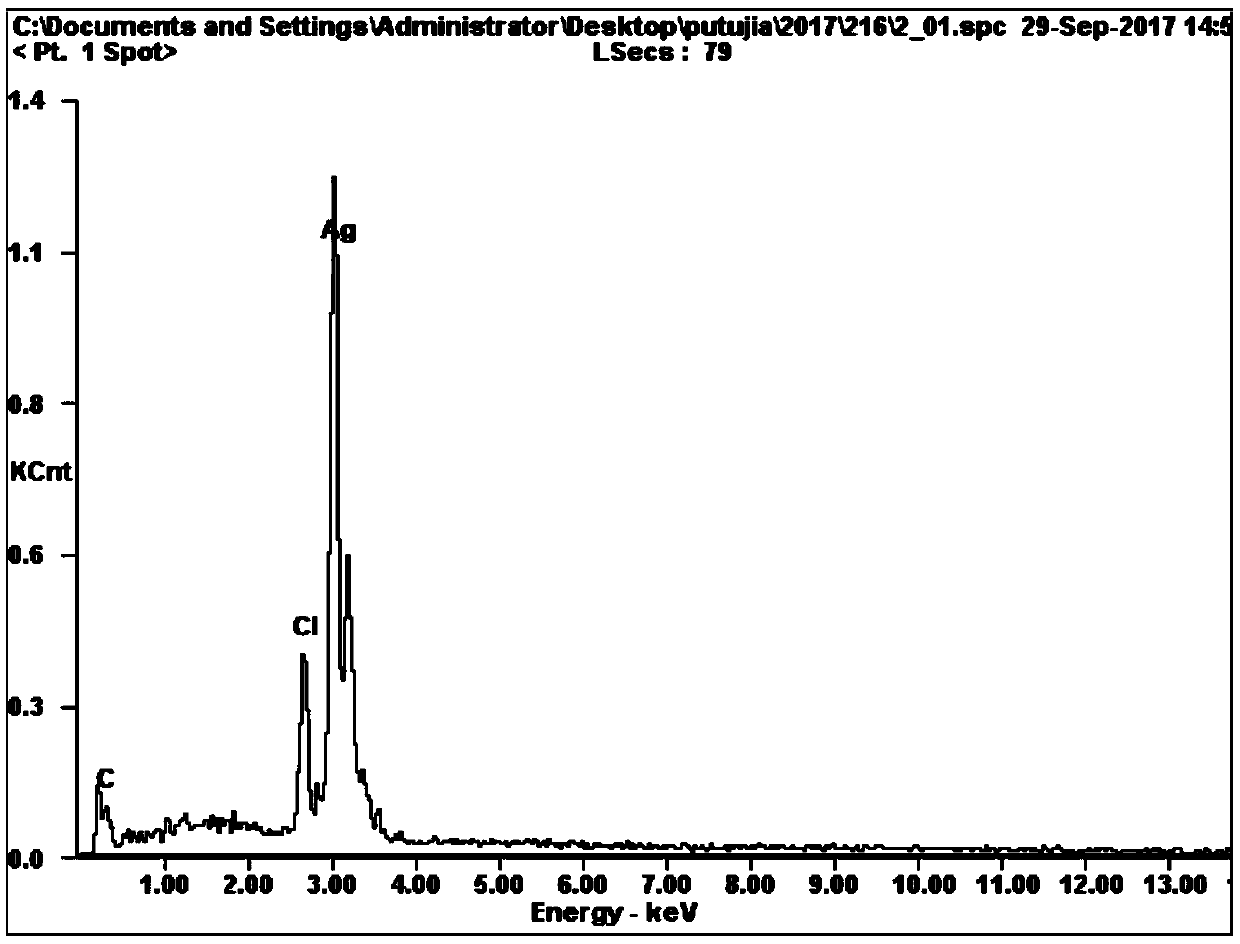

Image

Examples

Embodiment 1

[0034] Weigh 4.8g AgNO 3 Analytical grade was dissolved in 500ml ultrapure water and stirred with a mixer. Weigh 8g NaCl analytical pure 400ml ultrapure water, slowly titrate the NaCl solution into AgNO under stirring 3 solution, resulting in the precipitation of fine-grained silver chloride powder. Pour off the water layer, wash it with ultrapure water, and carry out 3000HZ ultrasonic pulverization at the same time, repeat the cleaning and pulverization several times, until the supernatant liquid is taken, and its conductivity is consistent with that of ultrapure water. Then, the silver chloride powder is first cleaned with ethanol, and then put into an oven for rapid drying under low-temperature vacuum, and the temperature is controlled not higher than 80° C. to obtain fine-grained silver chloride powder. Take 90wt% tap density 3.5g / cm 3 , burning loss 0.9%, specific surface area 1.7m 2 / g, the spherical silver powder with a maximum particle diameter of less than 3 micro...

Embodiment 2

[0039] Prepare silver chloride powder according to the method for embodiment 1, get 40wt% tap density 1.5~5.5g / cm 3 , burning rate 2 Silver / silver chloride powder is fully mixed with flaky silver powder with a maximum flake diameter of less than 25 microns and 60 wt% silver chloride powder with a particle size of 0.2 to 6 microns.

[0040] Add 30wt% vinyl chloride resin and modified polyester to a mixed solvent of 70wt% dimethyl succinate, dimethyl glutarate, dimethyl adipate, and butyl acetate, using a high-speed disperser Stir, the temperature does not exceed 70 ° C, after the resin is completely dissolved, cool down to room temperature, disperse at high speed for 40 minutes to make an organic vehicle.

[0041] 38wt% silver / silver chloride powder and 62wt% organic vehicle were ground and dispersed with a three-roll mill, and finally degassed under reduced pressure to obtain silver / silver chloride electrode slurry.

[0042] The prepared silver / silver chloride electrode paste...

Embodiment 3

[0044] Prepare silver chloride powder according to the method for embodiment 1, get 60wt% tap density 5.6g / cm 3 , burning loss 0.9%, specific surface area 1.3m 2 / g, spherical silver powder with maximum particle size 3 , burning loss rate2 / g, silver flake powder with a maximum flake diameter of <25 microns is fully mixed with 20 wt% silver chloride powder with a particle diameter of 0.2 to 6 microns to form silver / silver chloride powder.

[0045] 40wt% vinyl chloride resin and modified polyester are added in the mixed solvent of 58wt% dimethyl succinate, dimethyl glutarate, dimethyl adipate, ethylene glycol butyl ether acetate, Use a high-speed disperser to stir, the temperature does not exceed 70°C, after the resin is completely dissolved, cool down to room temperature, add 2wt% blocked isocyanate, and disperse at high speed for 40 minutes to make an organic vehicle.

[0046] Grind and disperse 60 wt% silver / silver chloride powder and 40 wt% organic vehicle using a three-ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com