Thermal barrier coating, as well as preparation method and application thereof, and aero-engine turbine blade

A technology of aero-engine and thermal barrier coating, which is applied in the direction of engine components, machines/engines, coatings, etc., can solve the problems of cracking and failure of thermal barrier coatings, achieve particle erosion resistance, and the preparation method is simple and good Anti-corrosion effect of molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

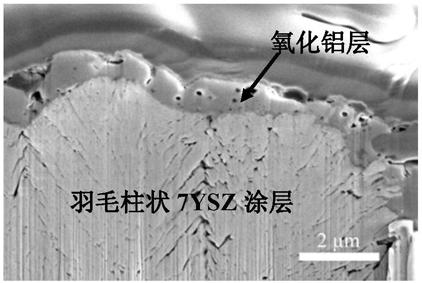

[0041] In addition, the present application also provides a method for preparing the above-mentioned thermal barrier coating, for example, including the following steps: preparing a 7YSZ ceramic layer by using a plasma spraying-physical vapor deposition method; preparing alumina on the surface of the 7YSZ ceramic layer by using magnetron sputtering technology layer and then vacuum treatment.

[0042] When the thermal barrier coating also includes a NiCoCrAlYTa alloy bonding layer, the NiCoCrAlYTa alloy bonding layer is first prepared by the plasma spraying-physical vapor deposition method, and then the plasma spraying-physical vapor deposition method is used on the surface of one side of the NiCoCrAlYTa alloy bonding layer Prepare a 7YSZ ceramic layer; then use magnetron sputtering technology to set an aluminum oxide layer on the surface of the 7YSZ ceramic layer away from the NiCoCrAlYTa alloy bonding layer, and vacuum process.

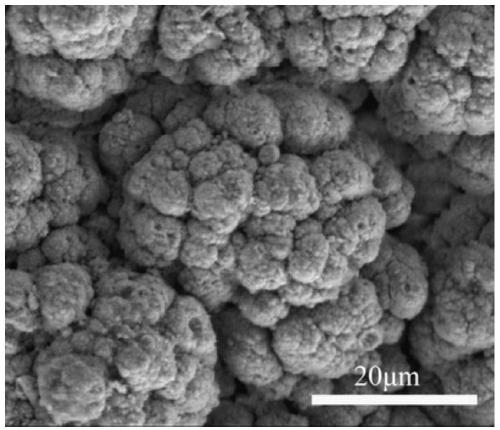

[0043]The inventors found that the microstruct...

Embodiment 1

[0069] Protect the turbine blades by using No. 60 grit for sandblasting. After sandblasting, use a brush to remove the residual grit, and then clean with high-pressure air and alcohol; protect the blades by spraying with PS-PVD to spray NiCoCrAlYTa alloy bonding layer , where the spraying power is controlled at 47kW, the argon gas is controlled at 93NLPM (standard liters per minute), and the hydrogen gas is controlled at 6NLPM. The thickness of the NiCoCrAlYTa alloy bonding layer formed after spraying is 25 μm.

[0070]After spraying the bonding layer, polish the blades, and then sandblast them with No. 220 grit. After sandblasting, use a brush to remove the residual grit, then clean with high-pressure air and alcohol, and finally use PS-PVD to spray the 7YSZ ceramic layer. Among them, the net spraying power is controlled at 57kW, the argon gas is controlled at 35NLPM, and the hydrogen gas is controlled at 65NLPM. The thickness of the 7YSZ ceramic layer formed after spraying ...

Embodiment 2

[0074] Protect the turbine blades by using No. 60 grit for sandblasting. After sandblasting, use a brush to remove the residual grit, and then clean with high-pressure air and alcohol. Spray the blades for protection by spraying NiCrAlY alloy bonding layer with PS-PVD , wherein the spraying power is controlled at 45kW, the argon gas is controlled at 90NLPM (standard liter per minute), and the hydrogen gas is controlled at 5NLPM. The thickness of the NiCoCrAlYTa alloy bonding layer formed after spraying is 20 μm.

[0075] After the bonding layer is sprayed, the blades are polished. After polishing, sandblast with 220 grit. After sandblasting, use a brush to remove the residual grit, then clean with high-pressure air and alcohol, and finally use PS-PVD to spray the 7YSZ ceramic layer. Among them, the net spraying power is controlled at 50kW, the argon gas is controlled at 30NLPM, and the hydrogen gas is controlled at 60NLPM. The thickness of the 7YSZ ceramic layer formed after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com