Multi-layer composite thermal protective material and preparation method thereof

A thermal protection material and composite technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem that thermal protection materials cannot meet the requirements of heat insulation, space and weight at the same time, and achieve The effect of short preparation cycle, high cost performance and flexible preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention provides a method for preparing a multilayer composite thermal protection material, comprising the following steps:

[0039] (1) Alternately stacking the heat insulating material with the first thickness and the anti-infrared radiation material with the second thickness to form a laminated prefabricated body;

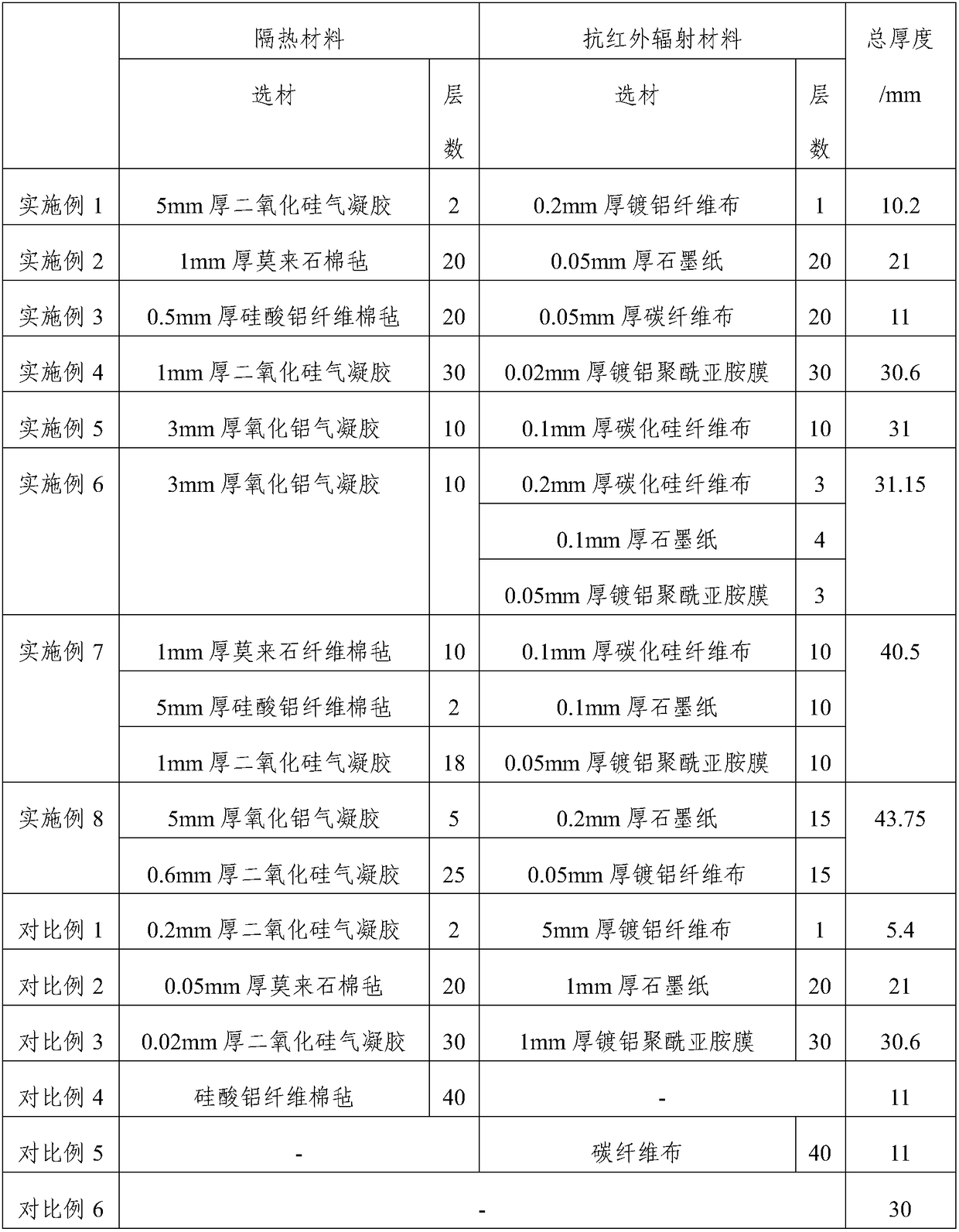

[0040] The heat insulating material is selected from one or more of glass fiber felts, aluminum silicate fiber felts, mullite fiber felts, silica aerogels, and alumina aerogels; preferably, the The first thickness is 0.5-5mm; the anti-infrared radiation material is selected from one or more of graphite paper, carbon fiber cloth, silicon carbide cloth, aluminized polyimide film, and aluminized fiber cloth; preferably, The second thickness is 0.02-0.2 mm. The number of layers can be controlled within 3 to 60 layers;

[0041] When stacking, it can be repeated sequentially in the order of heat insulation material and anti-...

Embodiment 1

[0049] (1) Select silica airgel with a thickness of 5mm as the heat insulation material, and aluminum-coated fiber cloth with a thickness of 0.2mm as the anti-infrared radiation material, and alternately stack them. The number of stacks is 3 layers, that is, 2 layers are separated Thermal material, 1 layer of anti-infrared radiation material, alternately laminate heat insulation material and anti-infrared radiation material in turn to form a laminated prefabricated body; the laminated prefabricated body is a sandwich structure, in which the core layer is an infrared The upper and lower sides are heat insulation materials;

[0050] (2) Cover the laminated prefabricated body with alkali-free glass fiber cloth to form the structure of the laminated prefabricated body with the outer layer of fiber cloth and the inner core, and then sew the fiber cloth and the laminated prefabricated body to make a multi-layer composite heat protection material.

[0051] After testing, the thermal...

Embodiment 2

[0053] (1) Select mullite wool felt with a thickness of 1mm as the heat insulation material, graphite paper with a thickness of 0.05mm as the anti-infrared radiation material, and alternately laminate the layers. The number of layers is 40 layers, that is, 20 layers of heat insulation materials, 20 layers Layers of anti-infrared radiation materials; when stacking, repeat the order of heat insulation materials and anti-infrared radiation materials to form a laminated prefabricated body;

[0054] (2) The laminated prefabricated body is stitched with quartz fiber thread, and the stitching method adopts a Z-direction stitching method to prepare a multi-layer composite heat protection material.

[0055] After testing, the density of the heat protection material is 0.15g.cm -3 , temperature resistance 700°C, room temperature thermal conductivity of 0.027W / m K, 600°C high temperature thermal conductivity of 0.040W / m K, 600°C-1500s flat quartz lamp test conditions under the heat insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com