A kind of acid and alkali resistant chemically modified PET composite material and preparation method thereof

A technology of chemical modification and composite material, applied in the field of chemically modified PET composite material and its preparation, can solve the problems of difficult to achieve miscibility, poor thermodynamic compatibility, unstable performance, etc., to meet mechanical properties, improve compatibility, etc. The effect of improving the stability of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

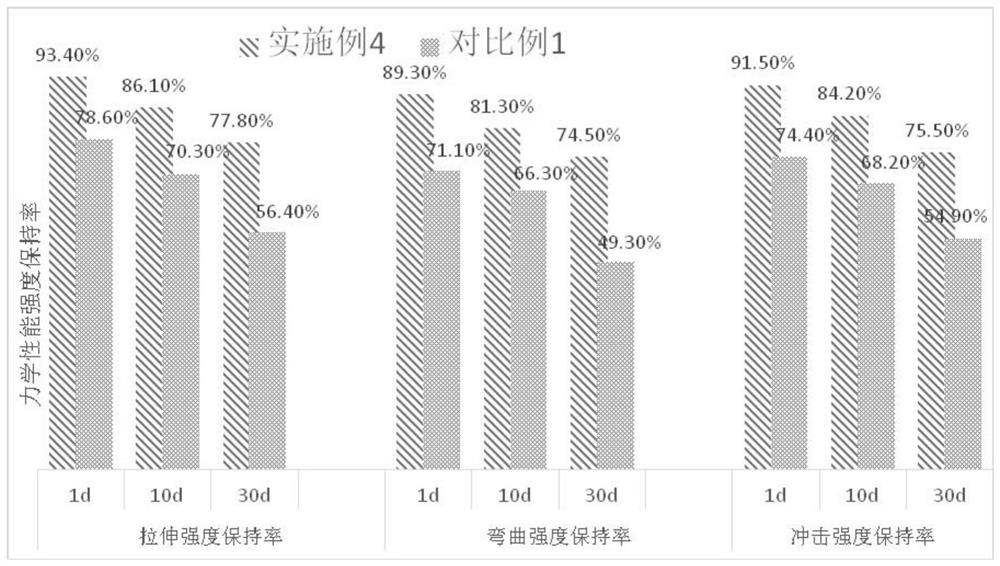

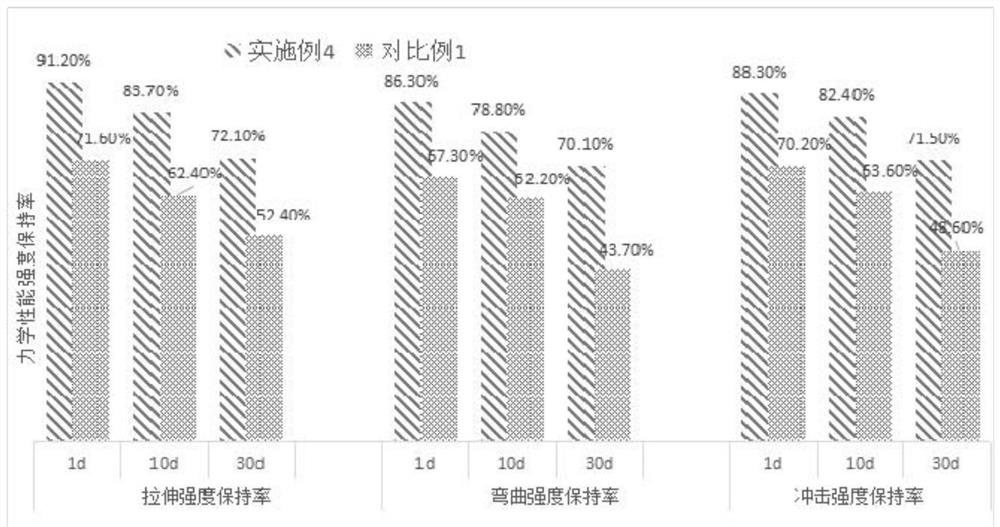

Examples

Embodiment Construction

[0035]In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field.

[0036] General synthesis method of modified PET resin:

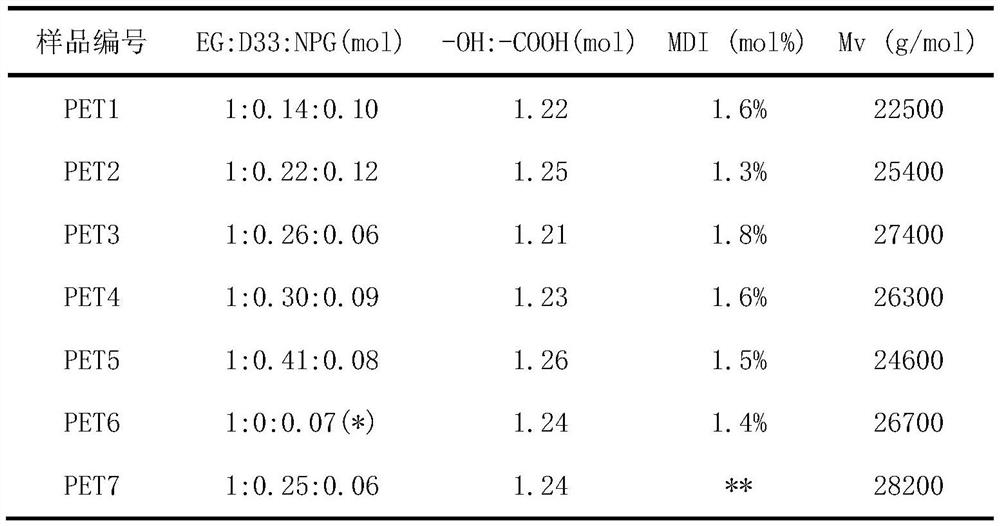

[0037] The preparation of the modified PET resin is obtained by polycondensation of terephthalic acid (TPA) and a diol mixture, and the diol mixture is ethylene glycol (EG) with a molar ratio of 1:0.1-0.3:0.03-0.15, The mixture of propoxylated bisphenol A (D33) and neopentyl glycol (NPG), the proportioning of terephthalic acid and dibasic alcohol is that dibasic alcohol is in excess of 20%-30% according to the stoichiometric ratio; and in polycondensation After the reaction is finished, add a certain amount of diphenylmethane diisocyanate (MDI) for end-capping treatment, and then cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com