Solid base catalyst and preparation process of 4-(2-furyl)-3-buten-2-one

A technology of solid base catalyst and production method, which is applied in the direction of molecular sieve catalyst, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., and can solve the problem of FA yield less than 60%, rapid decline in catalyst activity, Problems such as poor recycling performance, to achieve the effects of improving selectivity and yield, avoiding multiple condensation side reactions, and making the preparation method easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

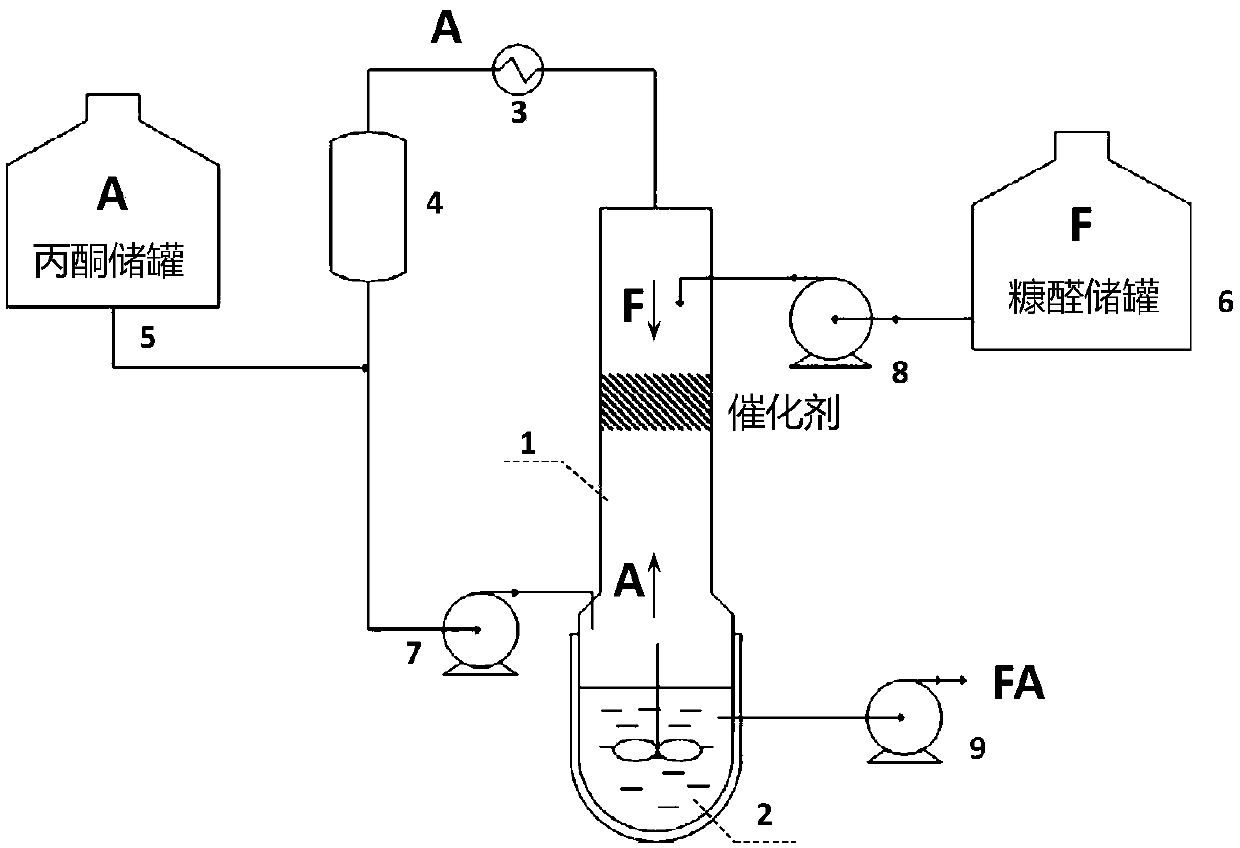

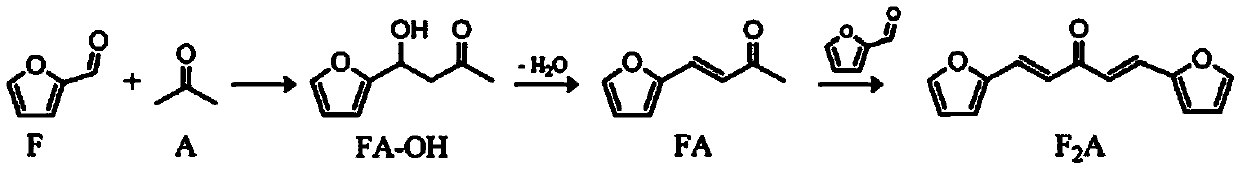

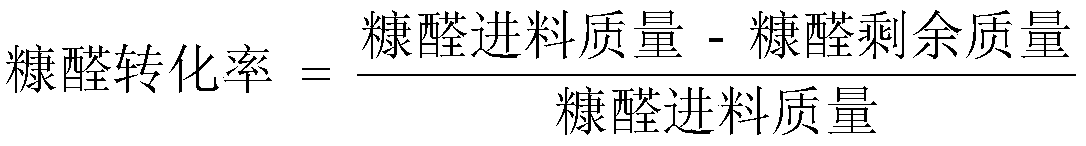

Method used

Image

Examples

Embodiment 1

[0044] Preparation of 2% NaOH-0.5% Nb 2 o 5 / anion resin catalyst

[0045] Dissolve 6.07g of niobium oxalate in 500mL of absolute ethanol, and adjust the stirring speed to 100 r / min at 30°C. After the metal salt is completely dissolved, 300g of anion exchange resin (specific surface area 180m 2 / g, average pore diameter 3nm, Dandong Mingzhu Special Resin Co., Ltd.) was slowly added to the above salt solution, ammonia water was added dropwise and the pH of the solution was kept between 8.5 and 9.0, and stirring was continued for 1h. Subsequently, after filtering and washing with deionized water, it was dried in an oven at 80°C for 6 hours to form solid particles.

[0046] Dissolve 6.00g of sodium hydroxide in 500mL of deionized water, and adjust the stirring speed to 100r / min at room temperature. After completely dissolving, slowly add the above-mentioned dried solid particles into the above-mentioned lye, and continue stirring for 1 h. Subsequently, the deionized water wa...

Embodiment 2

[0048] Preparation of 5%KOH-1%TiO 2 / magnesium oxide catalyst

[0049] Dissolve 12.78g of tetrabutyl titanate in 500mL of absolute ethanol, and adjust the stirring speed to 100r / min at 35°C. After the metal salt is completely dissolved, 300g of magnesium oxide (specific surface area 160m 2 / g, average pore diameter 2.5nm, Weifang Haililong Magnesium Industry Co., Ltd.) was slowly added to the above salt solution, ammonia water was added dropwise and the pH of the solution was kept between 8.0 and 8.5, and the stirring was continued for 2h. Subsequently, after filtering and washing with deionized water, it was dried in an oven at 80°C for 6 hours to form solid particles.

[0050] Dissolve 15.00 g of potassium hydroxide in 500 mL of deionized water, and adjust the stirring speed to 100 r / min at room temperature. After completely dissolving, slowly add the above-mentioned dried solid particles into the above-mentioned lye, and continue stirring for 1 h. Subsequently, the deio...

Embodiment 3

[0052] Preparation of 3%CsOH-2%ZrO 2 / Magnesium aluminum hydrotalcite catalyst

[0053] Dissolve 13.79g of zirconium hydrogen phosphate in 500mL of absolute ethanol, and adjust the stirring speed to 100r / min at 35°C. After the metal salt is completely dissolved, 300g magnesium aluminum hydrotalcite (specific surface area 200m 2 / g, with an average pore size of 2nm, Beijing Aili Wensen Chemical Co., Ltd.) was slowly added to the above salt solution, ammonia water was added dropwise and the pH of the solution was kept between 8.5 and 9.0, and stirring was continued for 1h. Subsequently, it was filtered, washed with deionized water, and dried in an oven at 80 °C for 6 h.

[0054] Dissolve 9.00 g of cesium hydroxide in 500 mL of deionized water, and adjust the stirring speed to 100 r / min at room temperature. After completely dissolving, slowly add the above-mentioned dried solid particles into the above-mentioned lye, and continue stirring for 1 h. Subsequently, the deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com