Preparation method and application of a water-soluble amphiphobic modified material

A modified material and water-soluble technology, applied in antifouling/underwater coatings, biocide-containing paints, latex paints, etc., can solve the volatile atmosphere pollution of organic solutions, weakening of modification effects, loss of amphiphobic properties, etc. problem, achieve the effect of reducing engineering cost, enhancing product adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Modification process based on amphiphobic polymer

[0029] The preparation method of water-soluble amphiphobic modified material is as follows:

[0030] (1) Evenly mix 1g of amphiphobic fluorosilane raw material with 30ml of absolute ethanol to obtain a transparent solution;

[0031] (2) Take 80ml of deionized water to dissolve 50g of fatty alcohol polyoxyethylene ether, and add 1.5g of glacial acetic acid;

[0032] (3) Put the above two solutions in a reaction kettle and stir at 80°C for 2 hours;

[0033] (4) After the reaction is completed, cool to room temperature for later use, and the desired stable water-soluble modified material can be obtained.

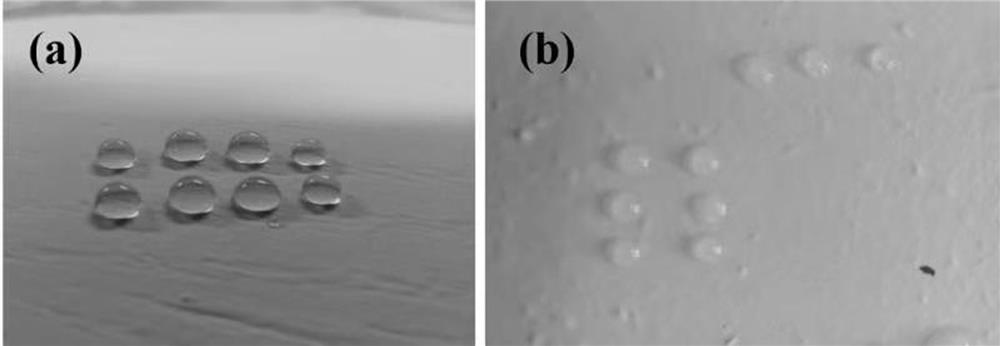

[0034] figure 1 The comparison results of the solubility in water of the fluorosilane raw material and the prepared modified amphiphobic material in this example are shown. in figure 1 (a) The phenomenon after adding water to fluorosilane, such as figure 1 As shown in (a), obvious delamination occurs af...

Embodiment 2

[0037] Example 2: Modification process based on a single hydrophobic raw material and a single oleophobic raw material

[0038] The preparation method of water-soluble amphiphobic modified material is as follows:

[0039] (1) Add 3.5 g of silicone oil (with hydrophobic and lipophilic properties) into 10 ml of butanol, and stir at 40°C for 1 h to obtain a homogeneous solution;

[0040] (2) Add 1.5 ml of perfluoroheptanoic acid (hydrophilic and oleophobic) into 10 ml of absolute ethanol, stir at 60°C for 0.5 h to dissolve;

[0041] (3) After being stabilized, put the above two solutions in a reactor for stirring and mixing, add 1.2 ml of polyacrylamide solution and 0.5 ml of silane coupling agent dropwise, and stir at 80°C for 1 h;

[0042] (4) After the reaction is completed, cool to room temperature for later use, and the desired stable water-soluble modified material can be obtained.

Embodiment 3

[0043] Example 3: Modification process based on hydrophobic nanoparticles and a single oleophobic raw material

[0044] The preparation method of water-soluble amphiphobic modified material is as follows:

[0045] (1) Take 1.2 g of silicone oil-modified silica powder (silicone oil content 10%), add it to 20 ml of ethanol solution, mix and stir to obtain a suspension;

[0046] (2) Mix 0.5 g of perfluoroheptanoic acid with 22 ml of isopropanol evenly, and add 0.3 g of polyethyleneimine and 0.6 g of polyvinylpyrrolidone to obtain a stable dispersion;

[0047] (3) Mix the above two solutions into the reactor, add 1.8 ml (0.5 mol / L) hydrofluoric acid dropwise, and heat at 60°C for 1.5 h;

[0048] (4) The required stable water-soluble modified material can be obtained after natural cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com