PTFE compound piston ring and preparation method thereof

A PTFE, piston ring technology, applied in the field of PTFE composite piston ring and its preparation, can solve the problems of small friction coefficient, thermal stability, poor dimensional stability, low dielectric strength, etc., and achieve excellent mechanical properties, comprehensive mechanical properties improvement, The effect of increasing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

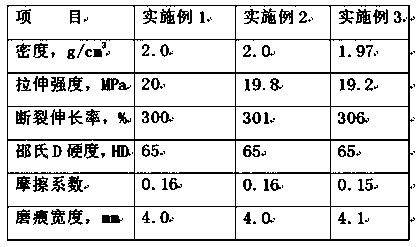

Examples

Embodiment 1-3

[0021] The preparation method of this PTFE composite piston ring is:

[0022] (1) Mix by dry method, add PTFE powder and PI powder in proportion to the high-speed mixer, stir evenly at high speed, take it out, and place it for 2~6h;

[0023] (2) Use a press for cold-press forming at a pressure of 10-30 MPa, hold the pressure for 1-5 minutes, and demould to obtain a preformed sample;

[0024] (3) Put the preformed sample into the sintering furnace and sinter at 380±5°C for 3~6h;

[0025] (4) Naturally cool the sintered blank to 60~120°C, then place it in a metal tube, heat it to 180~260°C, with a heating rate of 8~30°C / h; keep it at a constant temperature; then drop it to 150°C~room temperature and take it out , the cooling rate is 5~12℃ / h;

[0026] (5) Machining the annealed blank to obtain a formed piston ring product.

[0027] Among them, PTFE is suspended fine powder with a particle size of 25 μm to 40 μm and an apparent density of 400 to 500 g / L. The particle size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com