A kind of preparation method of nickel oxide-based composite semiconductor nanofiber

A composite semiconductor, nanofiber technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of poor repeatability, limited application of nickel oxide materials, and harsh reaction conditions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]The method of preparing the nickel oxide-based composite semiconductor nanofibers of the present embodiment includes the following steps:

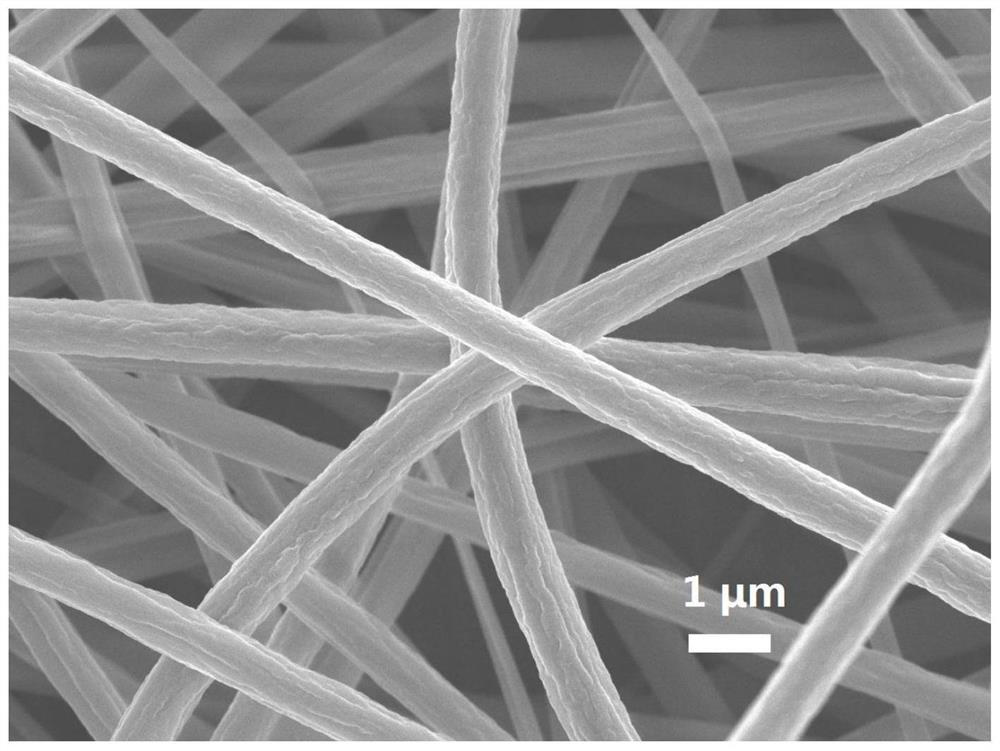

[0027]Step 1. Preparation of PAN nanofibers by electrospinning, this method is a conventional method;

[0028]Step 2, the PAN nanofibers obtained by the step were heat-treated to obtain carbon nanofibers, i.e. CNFS; the heat treatment method is: first access the air atmosphere into the atmosphere furnace, the furnace temperature rises from the room to 270 ° C, temperature rise rate It was 2 ° C / min, and the temperature was heated to 270 ° C. Then, the nitrogen atmosphere was introduced into the atmosphere furnace, and the furnace temperature rose from 270 ° C to 800 ° C, and the temperature of the temperature was 5 ° C / min, and the temperature was temperature to 800 ° C. Then cool to room temperature naturally;

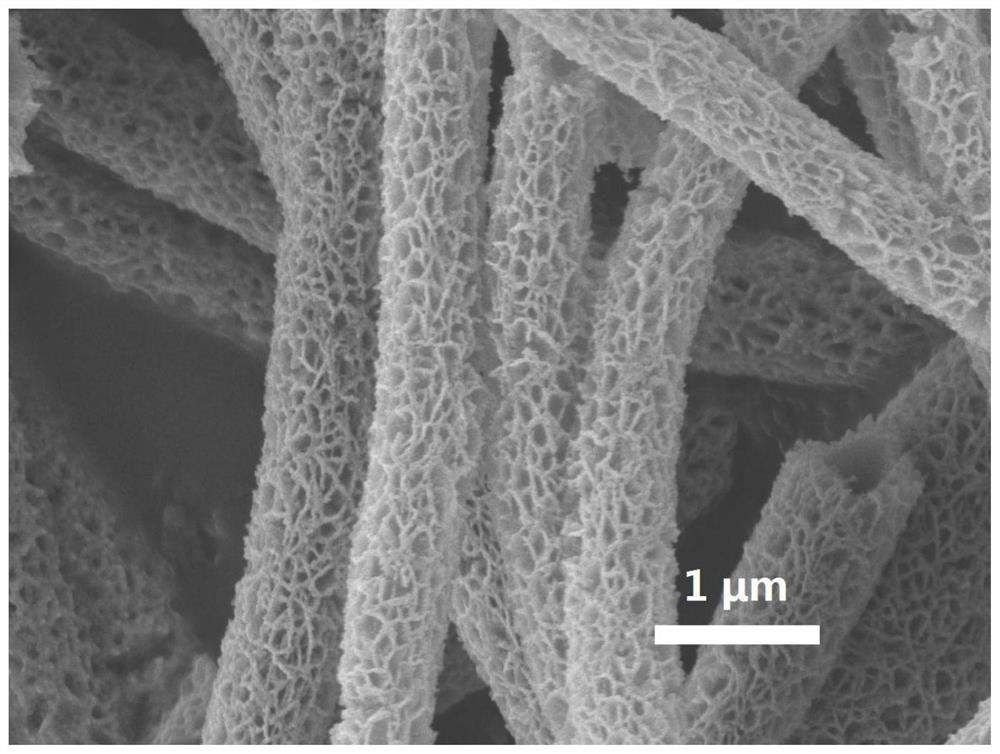

[0029]Step three, soak the carbon nanofibers obtained in step two in Niso at 90 ml concentration of 0.225 mol / L4Aqueous solution, t...

Embodiment 2

[0039]The method of preparing the nickel oxide-based composite semiconductor nanofibers of the present embodiment includes the following steps:

[0040]Step 1. Preparation of PAN nanofibers by electrospinning, this method is a conventional method;

[0041]Step 2, the PAN nanofibers obtained by the step were heat-treated to obtain carbon nanofibers, i.e. CNFS; the heat treatment method is: first access the air atmosphere into the atmosphere furnace, the furnace temperature rises from the room to 270 ° C, temperature rise rate It was 2 ° C / min, and the temperature was heated to 270 ° C. Then, the nitrogen atmosphere was introduced into the atmosphere furnace, and the furnace temperature rose from 270 ° C to 800 ° C, and the temperature of the temperature was 5 ° C / min, and the temperature was temperature to 800 ° C. Then cool to room temperature naturally;

[0042]Step three, soak the carbon nanofibers obtained by step two in Niso at 90 ml concentration of 0.63 mol / L4Aqueous solution, to...

Embodiment 3

[0048]The method of preparing the nickel oxide-based composite semiconductor nanofibers of the present embodiment includes the following steps:

[0049]Step 1. Preparation of PAN nanofibers by electrospinning, this method is a conventional method;

[0050]Step 2, the PAN nanofibers obtained by the step were heat-treated to obtain carbon nanofibers, i.e. CNFS; the heat treatment method is: first access the air atmosphere into the atmosphere furnace, the furnace temperature rises from the room to 270 ° C, temperature rise rate It was 2 ° C / min, and the temperature was heated to 270 ° C. Then, the nitrogen atmosphere was introduced into the atmosphere furnace, and the furnace temperature rose from 270 ° C to 800 ° C, and the temperature of the temperature was 5 ° C / min, and the temperature was temperature to 800 ° C. Then cool to room temperature naturally;

[0051]Step three, soak the carbon nanofibers obtained in step two in Niso at 90 ml concentration of 0.225 mol / L4Aqueous solution, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com