Construction method of foam concrete landscape restoration system

A technology of foam concrete and construction methods, applied in the direction of botanical equipment and methods, filling, artificial islands, etc., can solve the problems of large impact on the stability of disaster-damaged subgrades, secondary disasters, difficult road landscape restoration, etc., and achieve convenient construction , reduce disturbance, and improve aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

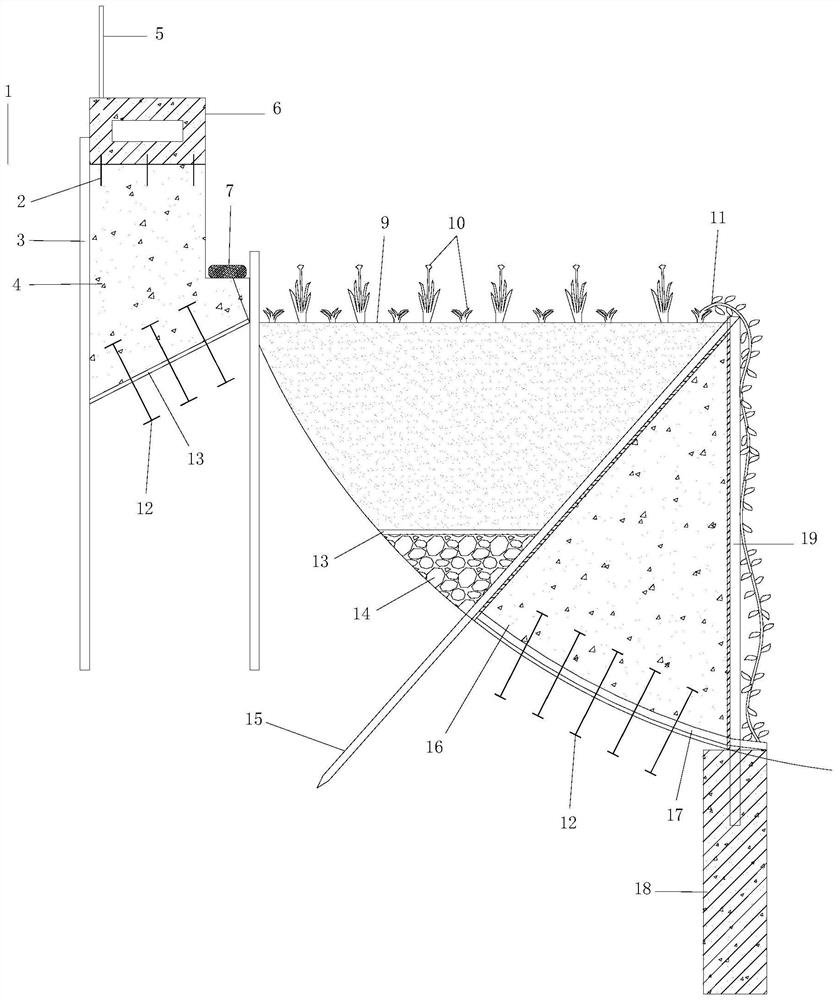

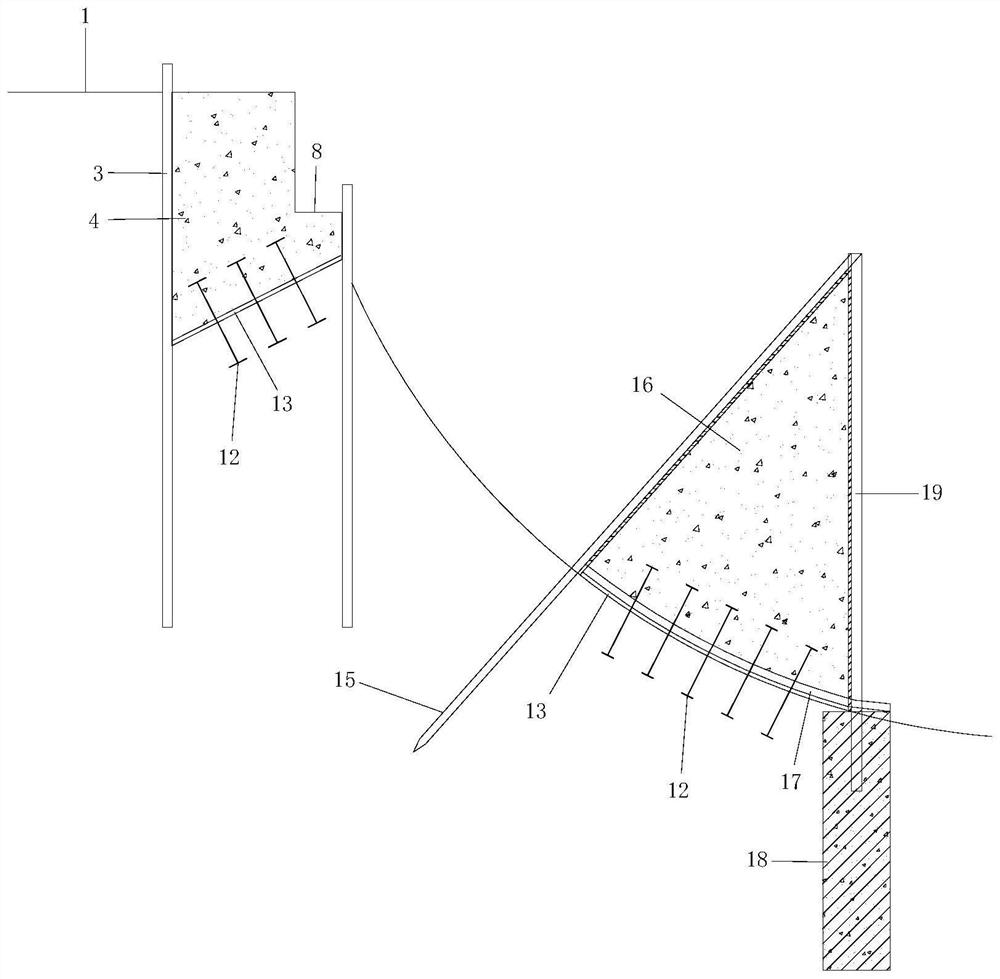

[0034] The foam concrete landscape restoration system includes the original roadbed 1, connecting bars 2, steel sheet piles 3, foam concrete wedge-shaped retaining walls 4, guardrails 5, hollow concrete roof beams 6, ecological bags 7, green platforms 8, planting soil 9 , green plants 10, hanging plants 11, two-way anchors 12, geotextiles 13, gravel layer 14, anchor rods 15, foam concrete fan-shaped retaining walls 16, drainage pipes 17, anti-sliding piles 18, vertical retaining frames 19 and Steel wire grid and geotextile composite 20, the foam concrete wedge-shaped retaining wall 4 is arranged on the slope side of the original roadbed 1, the wedge-shaped contact surface is fixedly connected by two-way anchors 12, and the steel sheet pile 3 is arranged on the foam concrete wedge-shaped retaining wall. 4 on both sides, the hollow concrete top beam 6 is arranged on the foam concrete wedge-shaped retaining wall 4, which is fixedly connected by connecting ribs 2, the guardrail 5 i...

Embodiment 2

[0039] The construction method of the foam concrete landscape restoration system is as follows: firstly, the original roadbed slope is cleared, and after the steel sheet piles are laid, the foam concrete wedge-shaped retaining wall is constructed, and the anti-sliding pile construction is carried out at the same time, and the vertical retaining frame is installed and the construction is carried out. The anchor rod is followed by the construction of the foam concrete fan-shaped retaining wall, then the backfilling and leveling of the green belt, the construction of the hollow concrete roof beam and the guardrail, and finally the construction of the green landscape layout. Specifically include the following steps:

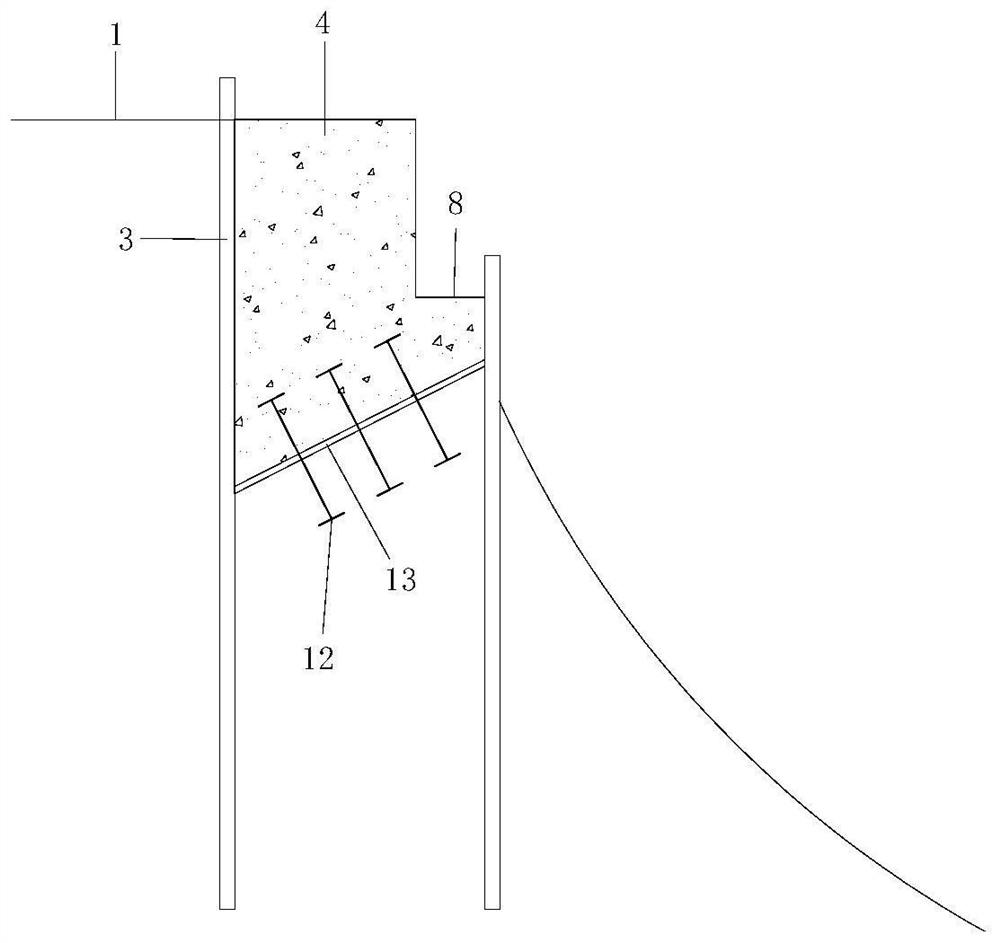

[0040] 1) as figure 2 As shown in the figure, clean up the damaged slope of the original subgrade 1, set two steel sheet piles 3 on the side of the original subgrade 1, and then excavate the foundation pit of the foam concrete wedge-shaped retaining wall 4 between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com