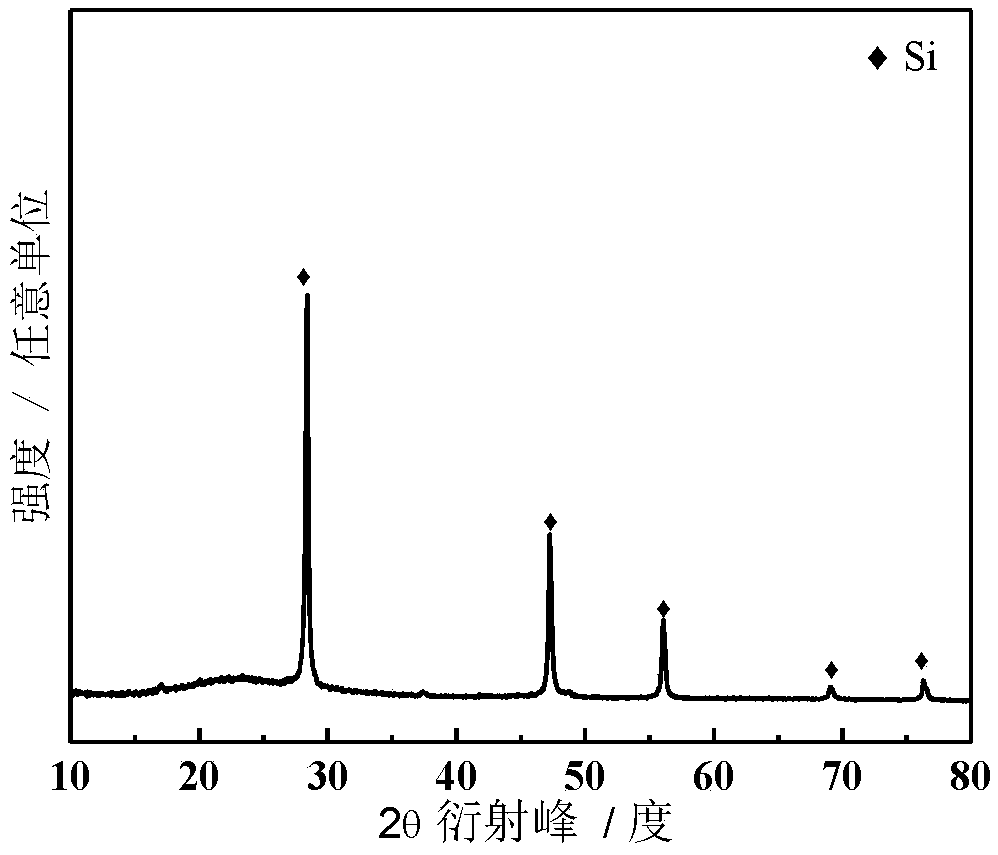

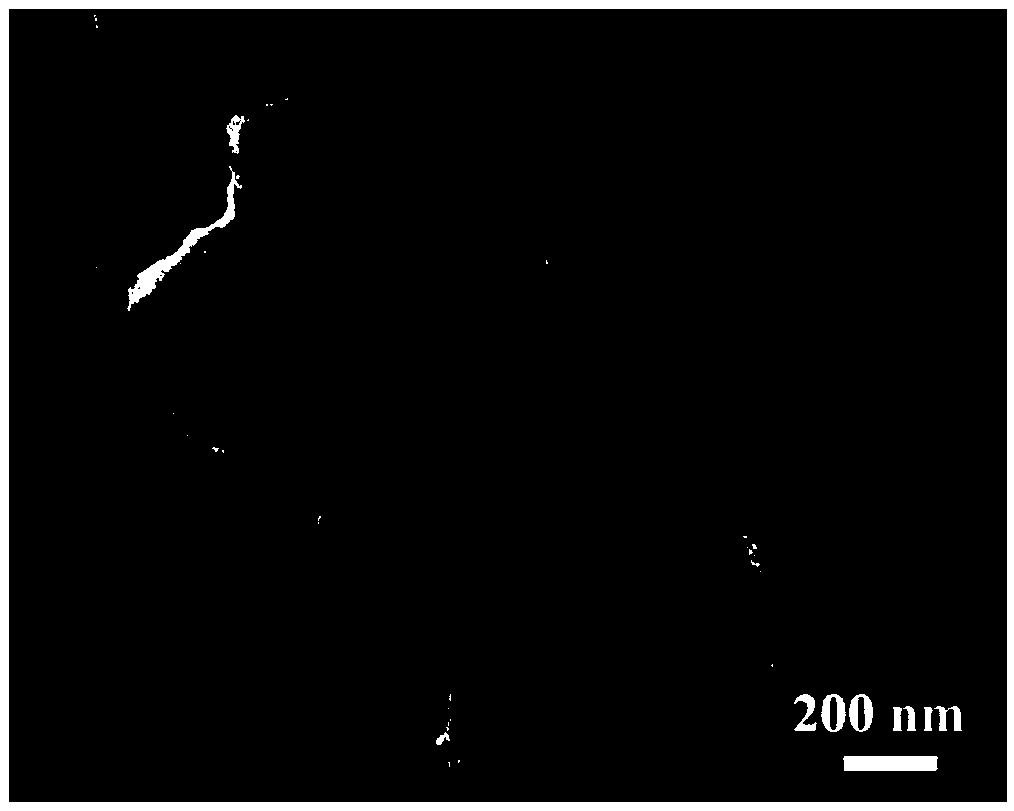

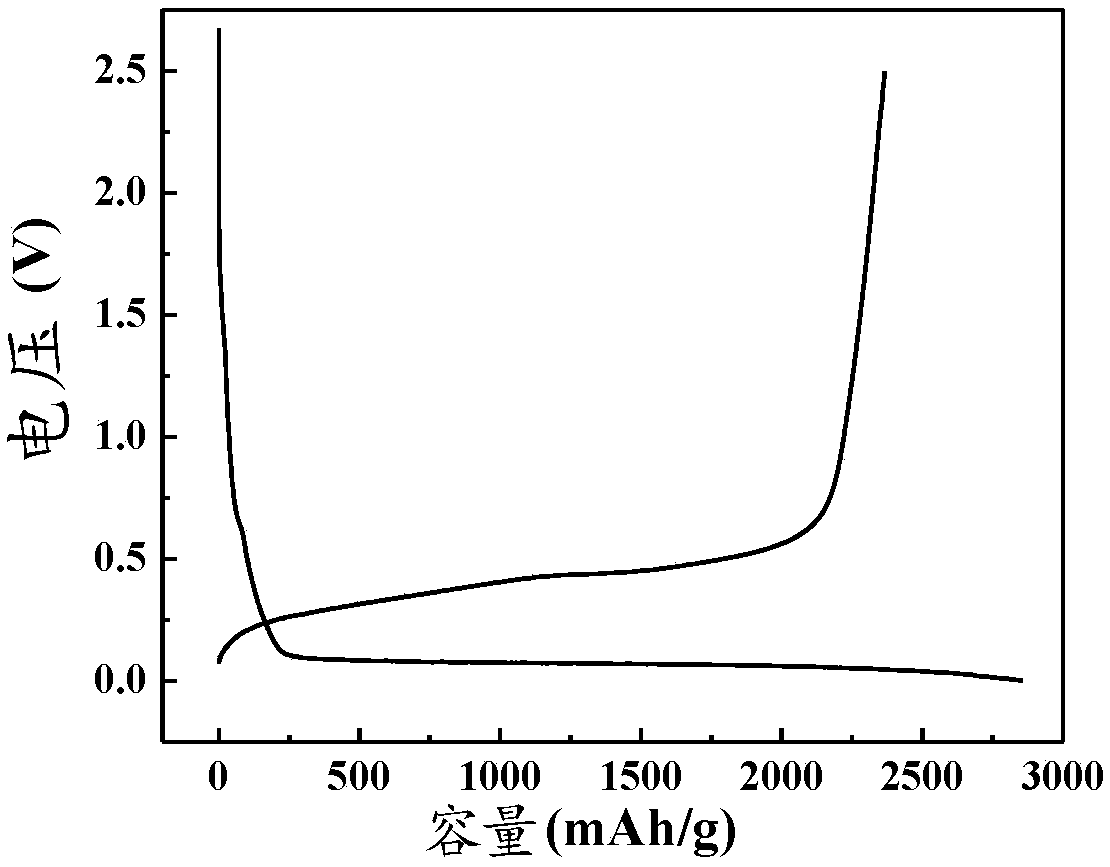

Silicon-based anode material and preparation method thereof and application thereof

A silicon-based negative electrode material, nano-silicon technology, applied in battery electrodes, electrical components, electrochemical generators, etc., to achieve the effects of improving cycle stability, low energy consumption, and uniform compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a silicon-based negative electrode material, comprising the following steps:

[0045] 1) First burn diatomite in air at 800°C for 2 hours, then wash the burnt product with 6mol / L hydrochloric acid for 12 hours, and wash it with deionized water until neutral to obtain pure silicon oxide;

[0046] 2) The pure silicon oxide prepared in step 1) is mixed with magnesium powder and sodium chloride through ball milling, the ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture; the mol ratio of magnesium powder to pure silicon oxide is 2: 1. The weight ratio of sodium chloride to pure silicon oxide is 6:1;

[0047]3) The mixture prepared in step 2) is placed in a tube furnace, and argon gas is introduced to carry out a magnesia thermal reduction reaction with a reaction temperature of 800° C. and a reaction time of 10 hours; to obtain a magnesia thermal reaction product;

[0048] 4) The magnesium thermal reaction produ...

Embodiment 2

[0062] A method for preparing a silicon-based negative electrode material, comprising the following steps:

[0063] 1) First burn kaolin in air at 800°C for 2 hours, then wash the burnt product with 6mol / L hydrochloric acid for 12 hours, and wash it with deionized water until neutral to obtain pure silicon oxide;

[0064] 2) The pure silicon oxide prepared in step 1) is mixed with aluminum powder and potassium chloride through ball milling, the ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture; the mol ratio of aluminum powder to pure silicon oxide is 4.0: 3. The weight ratio of potassium chloride to pure silicon oxide is 7:1;

[0065] 3) placing the mixture prepared in step 2) in a tube furnace, feeding argon gas, and performing a magnesia thermal reduction reaction, the reaction temperature is 850°C, and the reaction time is 5 hours; a magnesia thermal reaction product is obtained;

[0066] 4) The magnesium thermal reaction product pr...

Embodiment 3

[0072] A method for preparing a silicon-based negative electrode material, comprising the following steps:

[0073] 1) Burn the quartz sand in the air at 800°C for 2 hours, then wash the burnt product with 6mol / L hydrochloric acid for 12 hours, and wash it with deionized water until neutral to obtain pure silica;

[0074] 2) The pure silicon oxide prepared in step 1) is mixed with magnesium powder and magnesium chloride through ball milling, the ball milling speed is 180r / min, and the ball milling time is 10 hours to obtain a mixture; the molar ratio of magnesium powder to pure silicon oxide is 2.1:1, The weight ratio of magnesium chloride to pure silicon oxide is 9:1;

[0075] 3) The mixture prepared in step 2) is placed in a tube furnace, and argon gas is introduced to carry out a magnesia thermal reduction reaction with a reaction temperature of 750° C. and a reaction time of 15 hours; a magnesia thermal reaction product is obtained;

[0076] 4) The magnesium thermal react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com