A cement-based cementitious material mixed with seawater

A cementitious material and cement-based technology, applied in the field of cement materials, can solve problems such as poor anti-penetration effect, and achieve the effects of excellent volume stability, dry shrinkage and low hydration heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

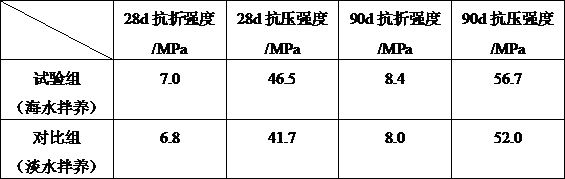

Embodiment 1

[0024] The present invention includes a seawater mixed cement-based cement-based cement-based cement-based gelation material, which includes 74% of the low-thermal silicate cement, 5% limestone powder, 15% geolar, 5% silicon ash and 1 % Nano Caco 3 .

[0025] In the actual production, due to the low-thermal silicate cement particles, limestone powder particles, genolite granules, silica granules and nano CaCO 3 The particle diameter of the particles cannot be represented by a specific number of devices, so the continuous level is adopted. Among them, the particle size of the low-thermosalite cement cement cement cement cement is 180 mesh ~ 400 mesh; the grain powder particle size range is 400 mesh ~ 800; the genus particle granularity range is 800 mesh ~ 2000; the particle size of the silicone granules is 2000 Entire ~ 8000 mesh; nano-Caco 3 Granular particles are greater than 8,000 mesh, namely nano-Caco 3 The maximum size is 8,000 mesh.

[0026] Active SiO in the lofincture 2 Th...

Embodiment 2

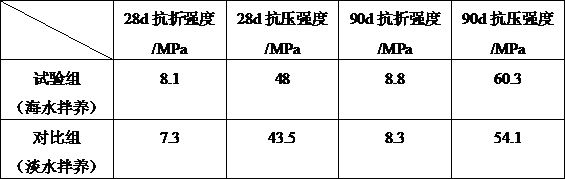

[0037] The present invention includes a seawater mixed cement-based cement-based cement-based cement-based cement-based cement-based cement-based cement-based cement, including 91.5% of the low expansion hypermantosilicate cement, 2% limestone powder, 5% 高, 1% silicon ash and 0.5 % Nano Caco 3 .

[0038] Among them, the particle size of the low-thermosalite cement cement cement cement cement is 180 mesh ~ 400 mesh; the grain powder particle size range is 400 mesh ~ 800; the genus particle granularity range is 800 mesh ~ 2000; the particle size of the silicone granules is 2000 Entire ~ 8000 mesh; nano-Caco 3 The particle size is greater than 8,000 mesh.

[0039] Active SiO in the lofincture 2 The content is greater than 50%; the main component of the silicon ash is an active SiO 2 The content is greater than 90%.

[0040]The above percentages by weight of the components weighed placed in the mixer, mix prepared cement-based binder, the binder was measured bulk density was 0.6956 ti...

Embodiment 3

[0050] The present invention includes a seawater mixed cement-based cement-based cement-based cement-based cement-based cement-based cement-based cement-based cement, including 91.5% of the low expansion hypermantosilicate cement, 2% limestone powder, 5% 高, 1% silicon ash and 0.5 % Nano Caco 3 .

[0051] Wherein the micro-expansion low heat Portland cement particle size range of 120 mesh to 400 mesh; particle size range of limestone powder 400 mesh to 1000 mesh; metakaolin particle size range of 600 mesh to 3000 mesh; silica fume particle size range of 1000 mesh to 8000 mesh; nano CaCO 3 The particle size is greater than 8,000 mesh.

[0052] Active SiO in the lofincture 2 The content is greater than 50%; the main component of the silicon ash is an active SiO 2 The content is greater than 90%.

[0053] The above percentages by weight of the components weighed placed in the mixer, mix prepared cement-based binder, the binder was measured bulk density was 0.6770 tight, generally high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com