Super-fine mercerized aluminum paste and preparation method thereof

A technology of ultra-fine wire and aluminum paste, applied in the direction of fibrous filler, dyed low molecular organic compound treatment, etc., can solve the problems of not enough softness and fineness, poor color white brightness, poor dispersion, etc., to achieve fine color, whiteness and brightness. The effect of improving and strong coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

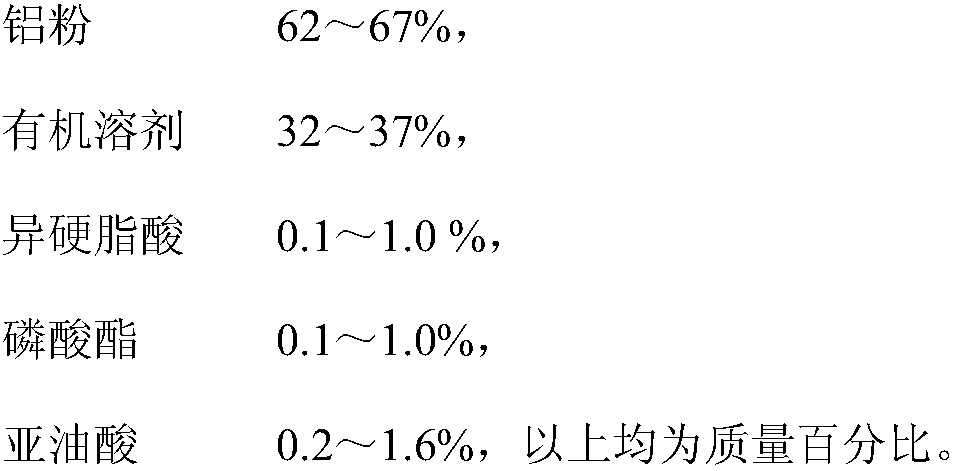

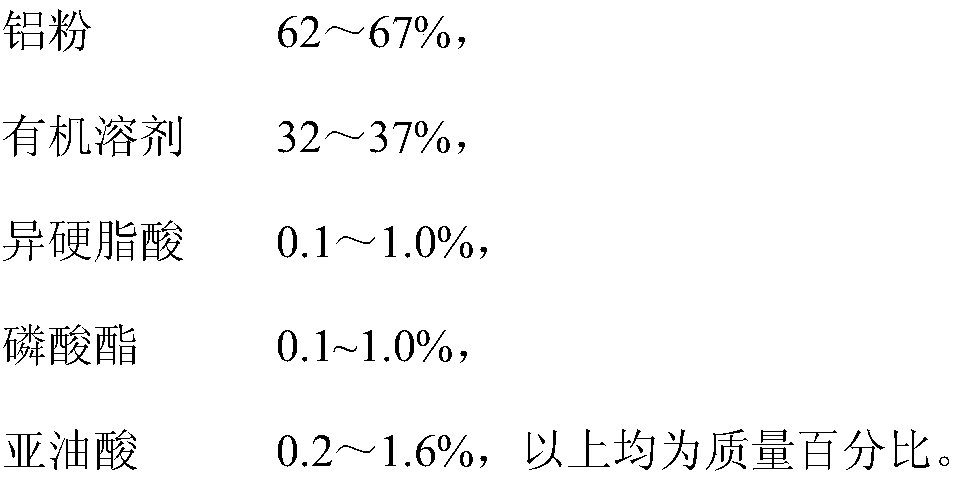

[0032] According to another aspect of the present invention, there is also provided a method for preparing the above-mentioned ultra-fine mercerized aluminum paste, comprising the steps of:

[0033] 1) Aluminum powder, organic solvent, linoleic acid and isostearic acid are ground for the first time, then added to phosphoric acid ester, and then ground for the second time,

[0034] 2) screening and pressing the material obtained in step 1) to make aluminum slurry filter cake,

[0035] 3) Kneading the aluminum paste filter cake with an organic solvent and a coupling agent to obtain an ultra-fine mercerized aluminum paste.

[0036]The organic solvent is a solvent for grinding, and its function is to isolate the aluminum powder from contact with air and water, and prevent the surface of the aluminum powder from being oxidized to form alumina. Isostearic acid, linoleic acid, and phosphate are used as lubricants and dispersants during grinding. Adding a dispersant to disperse the a...

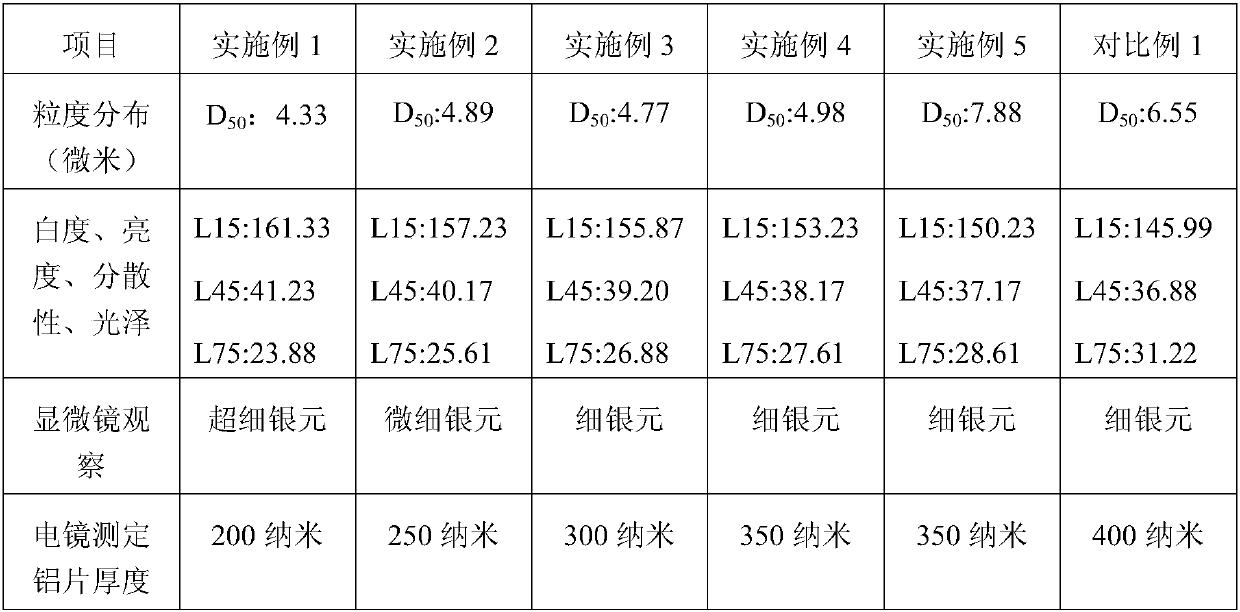

Embodiment 1

[0048] Get atomized spherical aluminum powder 80kg (D 50 =1um), D70 and 150# mixed solvent oil 160kg, the mass ratio of D70 solvent oil and 150# solvent oil is 4:1, linoleic acid 1.5kg, isostearic acid 1.0kg, add to 900mm (diameter)*1500mm (length) of the horizontal ball mill (2000 kg of steel balls with a diameter of 1.0 mm have been added to the ball mill), rotate the ball mill at a speed of 45 rpm, so that the temperature of the outer wall of the ball mill does not exceed 50 ° C, stop for 42 hours after grinding, and then Add 1 kg of phosphate ester, grind for another 2 hours and stop;

[0049] Then obtain about 100 kg of filter cake with a solid content of about 76% after discharging, passing through a 400-mesh sieve, and press filtration;

[0050] Then put it into a kneader and add 15kg of D40 mineral spirits and 0.7kg of coupling agent to stir evenly and knead for 20 minutes to produce about 115.7kg of superfine mercerized aluminum paste with a solid content of about 66...

Embodiment 2

[0053] Get atomized spherical aluminum powder 70kg (D 50 =1um), D70 and 150# mixed solvent oil 155kg, the mass ratio of D70 solvent oil and 150# solvent oil is 3:1, linoleic acid 1.0kg, isostearic acid 1.2kg, add to 1000mm (diameter)*2000mm (length) of the horizontal ball mill (3000kg of bearing steel balls with a diameter of 0.8mm have been added to the ball mill), rotate the ball mill at a speed of 40 rpm, so that the temperature of the outer wall of the ball mill is lower than 55°C, stop the mill for 36 hours, and then Add 1.2kg of phosphoric acid ester, grind for another 2 hours and stop the machine;

[0054] Afterwards, obtain about 90 kg of a filter cake with a solid content of 76% after discharging, crossing 600 mesh sieve screening, and pressure filtration;

[0055] Then put it into a kneader, add 18kg of D40 and D70 mixed solvent oil and 0.756kg of coupling agent, stir evenly, and knead for 30 minutes to produce about 108.7kg of ultra-fine mercerized aluminum paste w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com