Polyimide with photochromic property and preparation method and application thereof

A photochromic, polyimide technology, applied in the field of material science, can solve the problems of chemical corrosion resistance, high and low temperature resistance and extreme environment, and achieve the effect of low requirements, simple and diverse preparation processes, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

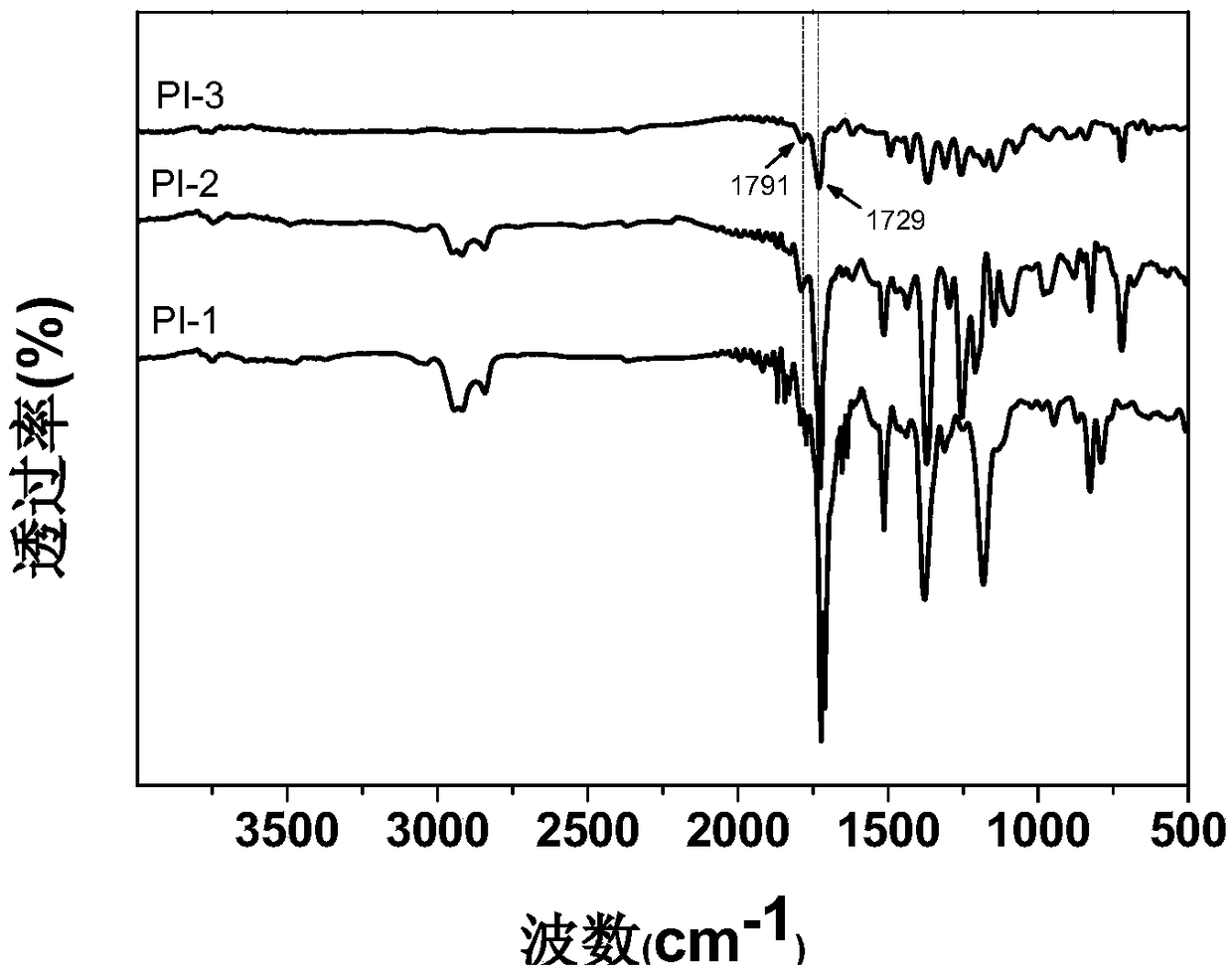

Examples

preparation example Construction

[0039] The above-mentioned preparation method of polyimide with photochromic performance is characterized in that:

[0040] Method (1): In a nitrogen or argon atmosphere, combine a diamine monomer containing a Y structure or a mixed diamine monomer containing a Y and Z structure with a dianhydride monomer containing an X structure or a diamine monomer containing a X and W structure Mixed dianhydride monomers are dissolved in an aprotic polar organic solvent at a molar ratio of 1:(1 to 1.2) (the molar ratio is most preferably 1:1.02), at -10°C to 40°C (most preferably -10°C ) stirring and reacting for 6 to 72 hours to obtain a polyamic acid solution, and then carry out dehydration imidization to obtain a photochromic polyimide such as the general formula (1); wherein the diamine monomer containing the Y structure is as shown in the structural formula ( Fives):

[0041]

[0042] where each J is independently taken from O or S, each E is independently taken from C or N, and e...

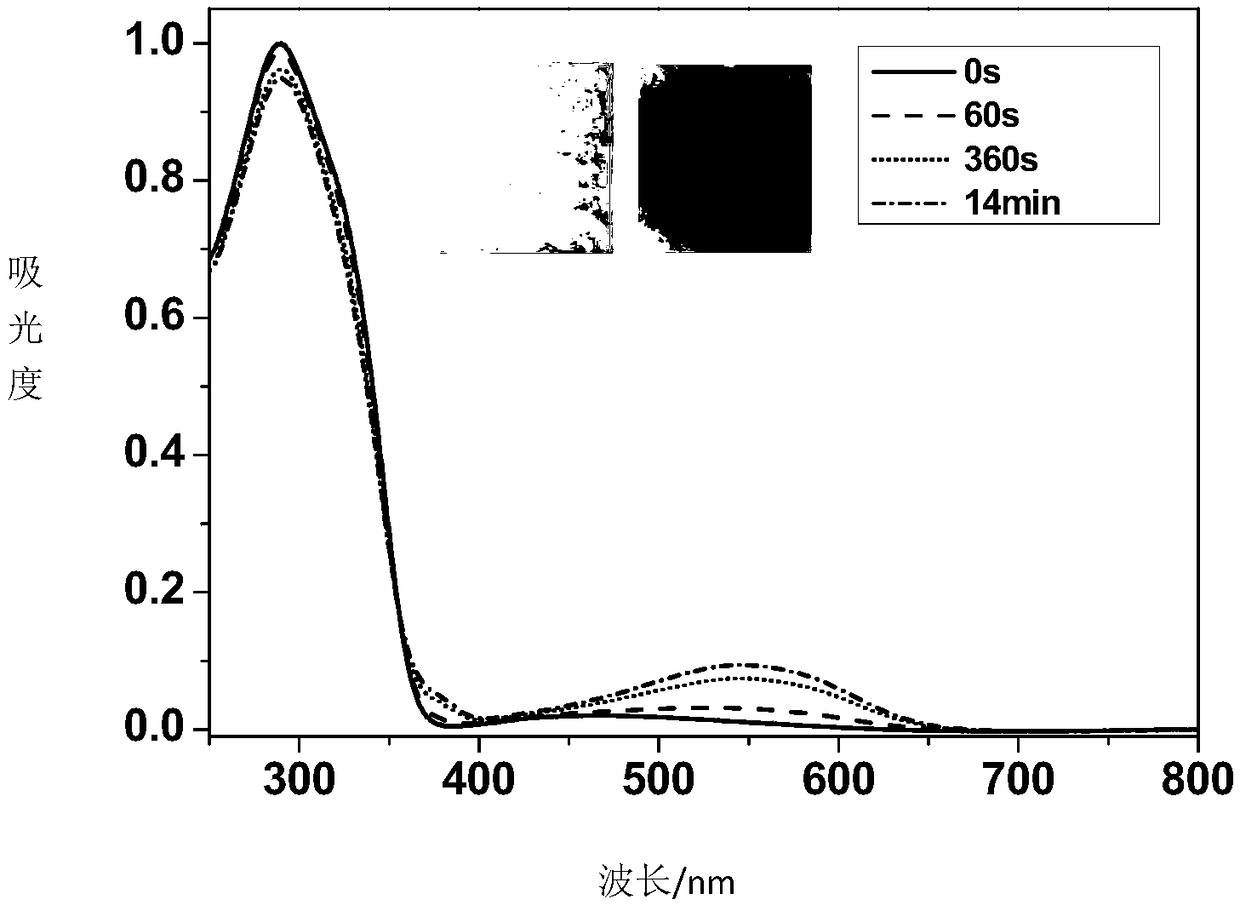

Embodiment 1

[0053] The diketone compound was synthesized by Friedel-Crafts acylation reaction of 2-methyl-5-chlorothiophene and glutaryl chloride, and diketone was self-coupled to obtain dichloride. Cyclopentene compound; dichlorocyclopentene compound reacts with tributyl borate to obtain borate compound, and reacts with p-bromoaniline and bromine-containing phthalate to obtain the target diamine mono-diamine with Y structure through suzuki reaction body.

[0054] At -10°C, 4.4264g (0.01mol) of diamine monomer and 23ml of N,N-dimethylformamide were added into a 100ml three-necked flask, and argon gas was introduced. After stirring and dissolving completely, 2.2865 g (0.0102 mol) of hydrogenated pyromellitic dianhydride was added, and stirring was continued at room temperature for 72 hours to obtain a homogeneous, transparent, viscous polyamic acid solution. Add 18.78ml of acetic anhydride and 7.51ml of pyridine into the obtained polyamic acid solution, continue to stir and react at room ...

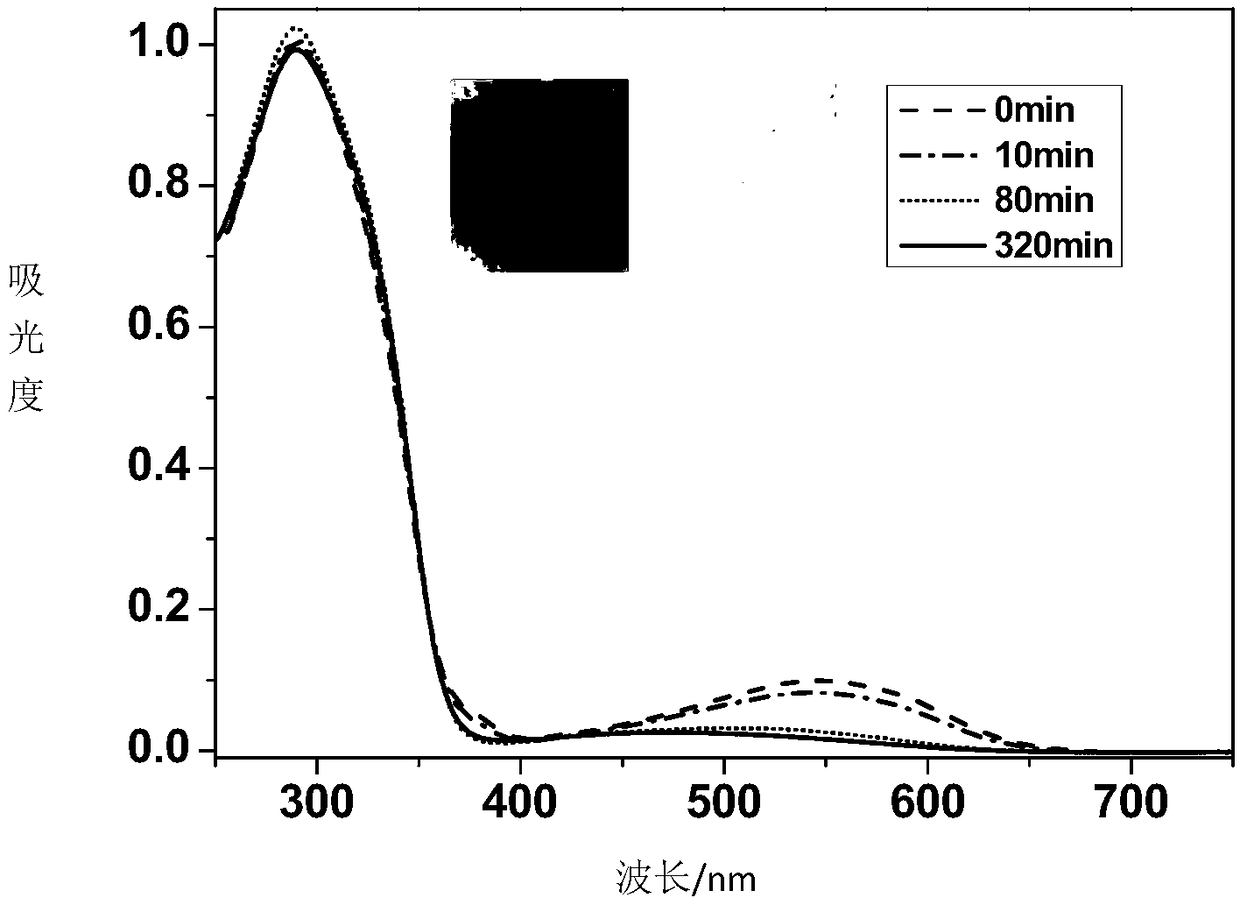

Embodiment 2

[0060] At -10°C, 4.4264g (0.01mol) of a diamine monomer having a Y structure and 23ml of N,N-dimethylformamide were added to a 100ml three-necked flask, and argon gas was introduced. After stirring and dissolving completely, add 4.5312g (0.0102mol) 4,4-hexafluoroisopropylphthalic anhydride (6-FDA), and continue to stir and react at room temperature for 72 hours to obtain a homogeneous, transparent, viscous Polyamic acid solution. Add 18.78ml of acetic anhydride and 7.51ml of pyridine into the obtained polyamic acid solution, continue to stir and react at room temperature for 24 hours, then slowly pour the obtained polyimide solution into 1L of methanol to obtain a powdery precipitate, filter out the precipitate Place in oven to dry. The 5% thermal weight loss temperature of this polyimide was 398 degreeC, and the glass transition temperature was 277 degreeC. PI-2 can be dissolved in dichloromethane, chloroform, tetrahydrofuran and strong polar N,N-dimethylformamide, N,N-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com