Method for producing high-quality biological feed from multiple bacteria through composite production

A compound fermentation and biological feed technology, applied in animal feed, animal feed, application, etc., can solve the problems of uneven fermentation of biological feed, low utilization rate and conversion rate of base materials, and achieve the promotion of growth and synthesis of metabolites, Solve the problem of biological resource utilization, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for producing high-quality biological feed through multi-strain compound fermentation, the method comprises the following steps:

[0050] 1. Activation and expansion of strains

[0051] 1) Pleurotus ostreatus: Select Guangwen Pleurotus ostreatus "Suping No. 1", and inoculate the strain of Pleurotus ostreatus into the improved PDA medium (the components of the medium are calculated as 1L: peeled potato 200g, glucose 20g, agar Powder 20g, KH 2 PO 4 2g, MgSO 4 ·7H 2 O 1g, FeSO 4 ·7H 2 O 5mg, CuSO 4 ·5H 2 O 0.3mg, vitamin B1 10mg, the balance is purified water, natural pH value) on the inclined surface, cultured at 28°C for activation, and after the mycelia covered the inclined surface, cut the mycelium block into 1cm 2 Small pieces, inoculate 1-2 pieces into 100mL liquid medium (the components of the medium are calculated as 1L: glucose 30g, yeast extract 4.1g, peptone 2.8g, wort juice 12.5ml, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O1.5g, zinc methionine 2.8mg...

Embodiment 2

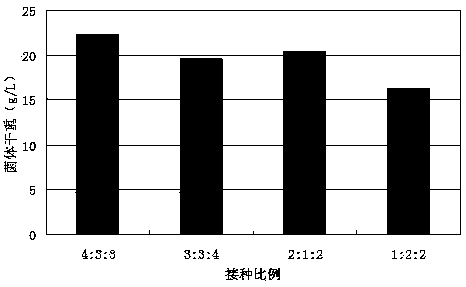

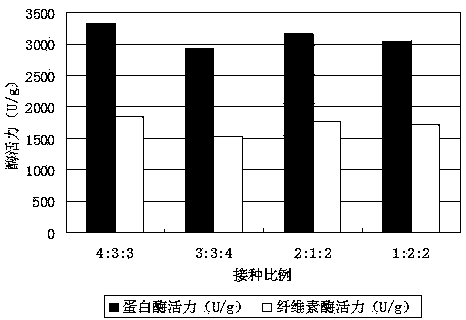

[0061] Effect of Different Inoculation Ratio on Composite Liquid Fermentation

[0062] According to the method described in embodiment 1, in step 2, 10% of total inoculum size is constant, and the inoculation ratio of flat mushroom, Candida utilis and Phanerochaete chrysosporium bacterial classification is respectively set to 4:3:3,3: 3:4, 2:1:2, 1:2:2, in order to study the influence of the inoculum ratio on the compound liquid fermentation, carry out the dry weight of the bacterial cell, protease activity and cellulase activity measurement to the obtained compound fermentation liquid, the result is as follows figure 1 and figure 2 shown.

[0063] from figure 1 and figure 2 It can be seen that when the strain ratio is 4:3:3, the dry weight of the thalline, protease activity and cellulase activity all reach the maximum value, indicating that under this strain ratio, Pleurotus ostreatus, Candida utilis and Phanerochaete chrysosporium reached a good symbiotic relationship,...

Embodiment 3

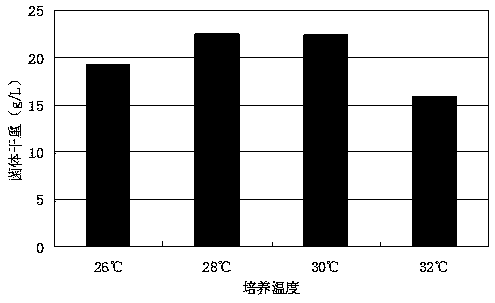

[0065] Effects of Different Culture Temperatures on Composite Liquid Fermentation

[0066] According to the method described in Example 1, the culture temperature in step 2 was set to 26°C, 28°C, 30°C, and 32°C respectively to study the influence of the culture temperature on the fermentation of the compound liquid, and to dry the obtained compound fermentation liquid. Weight, protease activity and cellulase assay, the results are as follows image 3 and Figure 4 shown.

[0067] from by image 3 It can be seen that when the culture temperature is 28°C and 30°C, the dry weight of the bacteria reaches the maximum value; Figure 4 It can be seen that when the culture temperature is 28°C, the activity of protease is the highest, but it is not significantly different from that at 30°C; when the culture temperature is 30°C, the activity of cellulase is the highest, but it is not significantly different from that at 28°C The difference in enzyme activity was not significant, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com