Aluminum alloy extrusion material with impact-resistant energy absorption characteristic and manufacturing method thereof

A technology of aluminum alloy and extruded material, which is applied in the field of aluminum alloy processing, can solve the problem of insufficient plasticity, impact toughness and stress corrosion cracking resistance, the inability to provide effective protection for the safety of cars and drivers, anti-collision beams and absorbers The energy box is easy to break and break, so as to improve the impact toughness and stress corrosion cracking resistance, improve the impact resistance and energy absorption effect, and eliminate the harm of plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

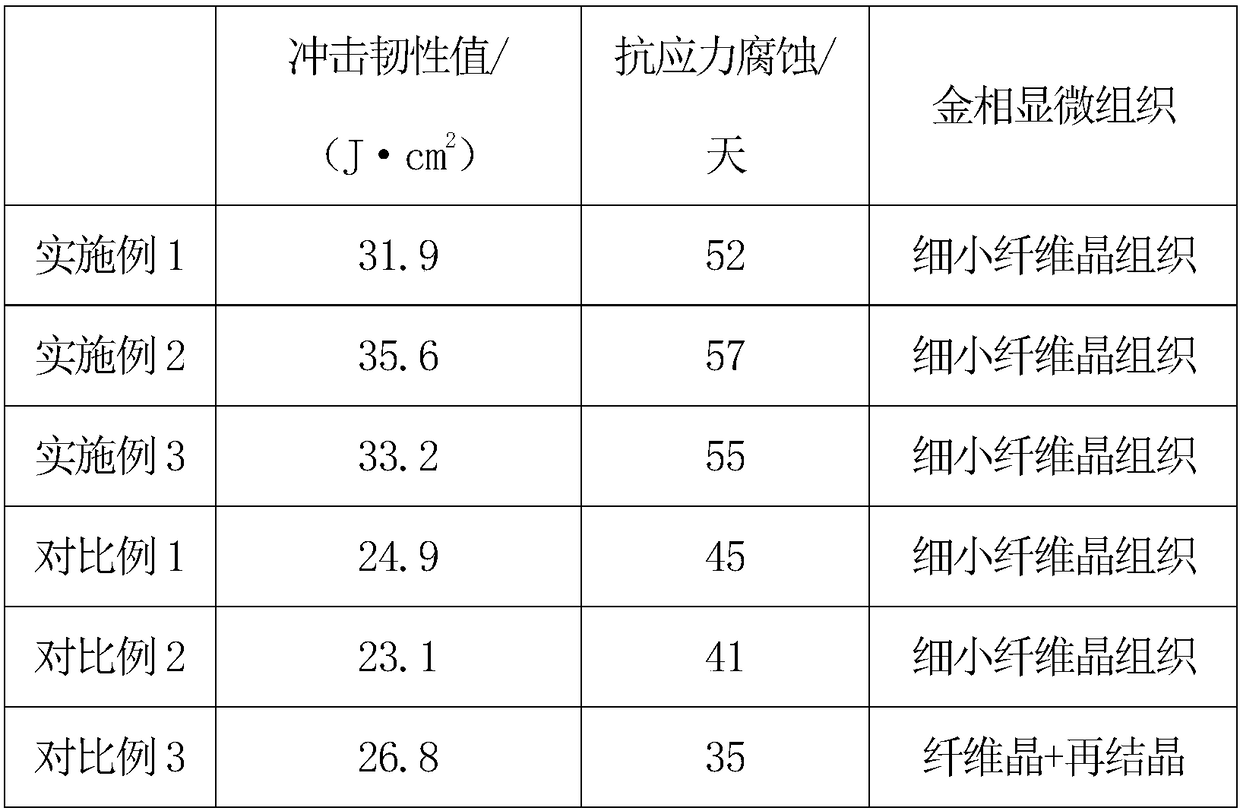

Examples

Embodiment 1

[0053] The aluminum alloy extrusion material is composed of the following components by mass percentage: Mg 0.8%, Si 1.0%, Mn 0.5%, Cr 0.21%, Er 0.07%, La 0.15%, Sr 0.08%, Ti 0.015%, B 0.003%, Fe≤0.15%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%; its manufacturing method includes the following steps:

[0054] The first step: according to the composition and mass percentage of the aluminum alloy extruded material, select the aluminum ingot of the brand Al99.70, the magnesium ingot of the brand Mg9980, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy, AlLa10 alloy, AlSr5 Alloy rods and AlTi5B1 alloy rods are used as raw materials for batching;

[0055] Step 2: Heat and melt the aluminum ingot at 750°C, then add magnesium ingot, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy and AlLa10 alloy, stir and melt to form an aluminum alloy liquid;

[0056] The third st...

Embodiment 2

[0064] The aluminum alloy extrusion material is composed of the following components by mass percentage: Mg 0.6%, Si 1.1%, Mn 0.4%, Cr 0.3%, Er 0.1%, La 0.1%, Sr 0.1%, Ti 0.01%, B 0.002%, Fe≤0.15%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%; its manufacturing method includes the following steps:

[0065] The first step: according to the composition and mass percentage of the aluminum alloy extruded material, select the aluminum ingot of the brand Al99.70, the magnesium ingot of the brand Mg9980, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy, AlLa10 alloy, AlSr5 Alloy rods and AlTi5B1 alloy rods are used as raw materials for batching;

[0066] Step 2: Heat and melt the aluminum ingot at 760°C, then add magnesium ingot, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy and AlLa10 alloy, stir and melt to form an aluminum alloy liquid;

[0067] The third step: u...

Embodiment 3

[0075] The aluminum alloy extrusion material is composed of the following components by mass percentage: Mg 0.9%, Si 0.9%, Mn 0.6%, Cr 0.15%, Er 0.05%, La 0.2%, Sr 0.05%, Ti 0.02%, B 0.004%, Fe≤0.15%, the balance is Al and other unavoidable impurities, the individual content of other unavoidable impurities is ≤0.05%, and the total amount is ≤0.15%; its manufacturing method includes the following steps:

[0076] The first step: according to the composition and mass percentage of the aluminum alloy extruded material, select the aluminum ingot of the brand Al99.70, the magnesium ingot of the brand Mg9980, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy, AlLa10 alloy, AlSr5 Alloy rods and AlTi5B1 alloy rods are used as raw materials for batching;

[0077] Step 2: Heat and melt the aluminum ingot at 740°C, then add magnesium ingot, AlSi20 alloy, AlMn10 alloy, AlCr10 alloy, AlEr10 alloy and AlLa10 alloy, stir and melt to form an aluminum alloy liquid;

[0078] The third step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com