Method for longitudinal stiffness control over high-pier large-span concrete continuous girder bridge and bridge

A technology of longitudinal stiffness and control method, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems that it is difficult to control the longitudinal stiffness of long-span continuous girder bridges with high piers, and the longitudinal stiffness of bridges is difficult to meet the vehicle-bridge coupling dynamic characteristics, etc., to achieve The effect of rationalizing the calculation process, ensuring accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

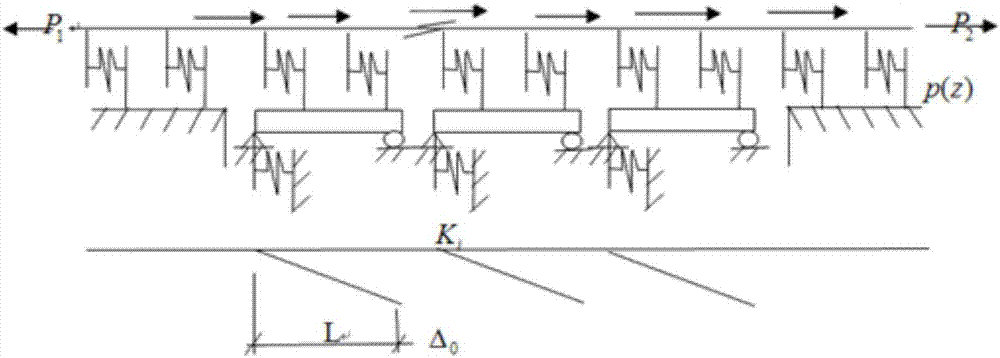

Image

Examples

Embodiment 1

[0068] According to the comparison of codes and pier line stiffness checking calculations, it can be seen that the longitudinal stiffness of long-span bridges with high piers is mainly controlled by seamless lines. In recent years, with the rapid development of railway construction and the advancement of seamless line technology on bridges, bridges The proportion of the line is gradually increasing, and the line inevitably needs to cross special areas such as traffic arteries, steep canyons, and wide rivers. In order to meet the requirements of the line across these areas, a large number of high-pier and long-span continuous beam bridges have appeared Due to the particularity of the structural characteristics of these bridges (long link length, weak stiffness, and large temperature span), the structural differences between adjacent bridge structures (such as differences in beam stiffness, beam material differences, and piers stiffness differences, etc.) and the complexity of na...

Embodiment 2

[0152] High-pier long-span concrete continuous girder bridge, the continuous girder bridge is a ballasted track, the high-pier long-span concrete continuous girder bridge obtained according to the longitudinal stiffness control method described in Example 1, the continuous girder bridge is in different temperature spans In this case, the longitudinal stiffness limit of the fixed pier and the track treatment measures shall meet Table 1:

[0153] Table 1 The rigidity limit of the longitudinal line of the fixed pier of the ballasted track continuous beam

[0154]

[0155] Listed in the table are the line stiffnesses required for single-line bridges, and double-line bridges are twice the values listed in the table.

[0156] Continuous girder bridges are different from simply supported girder bridges. As the length of continuous girders increases, the expansion force of the rails, the rapid relative displacement of the girders and rails, and the value of the cracks in the rail...

Embodiment 3

[0178] High-pier long-span concrete continuous girder bridge, the continuous girder bridge is a ballastless track, the high-pier long-span concrete continuous girder bridge obtained according to the above-mentioned longitudinal stiffness control method, the continuous girder bridge under different temperature span conditions, The longitudinal stiffness limit of the fixed pier and the treatment measures for the track meet Table 5.

[0179] Table 5 Limits of longitudinal line stiffness of ballastless track continuous beam fixed pier

[0180]

[0181]

[0182] Listed in Table 5 are the required line stiffnesses for single-line bridges, and double-line bridges are twice the values listed in Table 5.

[0183] Compared with the ballasted track, the ballastless track has better stability, the fastener resistance is larger, and there is no problem of track stability degradation under the action of braking force. According to the latest "Code for the Design of Seamless Railway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com