A kind of preparation method of two-way shape memory fiber

A technology of memory fiber and twin-screw extruder, which is applied in the direction of fiber chemical characteristics, melt spinning method, stretch spinning method, etc., to achieve good shape recovery process, simple preparation process, and shorten the effect of crosslinking reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The quality of benzophenone, triallyl isocyanurate and EVA resin was mixed with 3g, 3g and 100g respectively and then extruded using a twin-screw extruder. The temperature of the heating zone of the extruder is set at 145, 145, 150, and 150°C, the speed of the screw host is 40rpm, the speed of the feeding rod is 30rpm, and the extrusion speed is 1m / min;

[0019] (2) The extruded melt is first drawn by the rollers installed in the ultraviolet light box, and its line speed is about 8m / min. About 10m / min, the draft ratio is about 10;

[0020] (3) The power of the ultraviolet lamp installed in this ultraviolet light box is 250W, and the length of the lamp tube is 30cm.

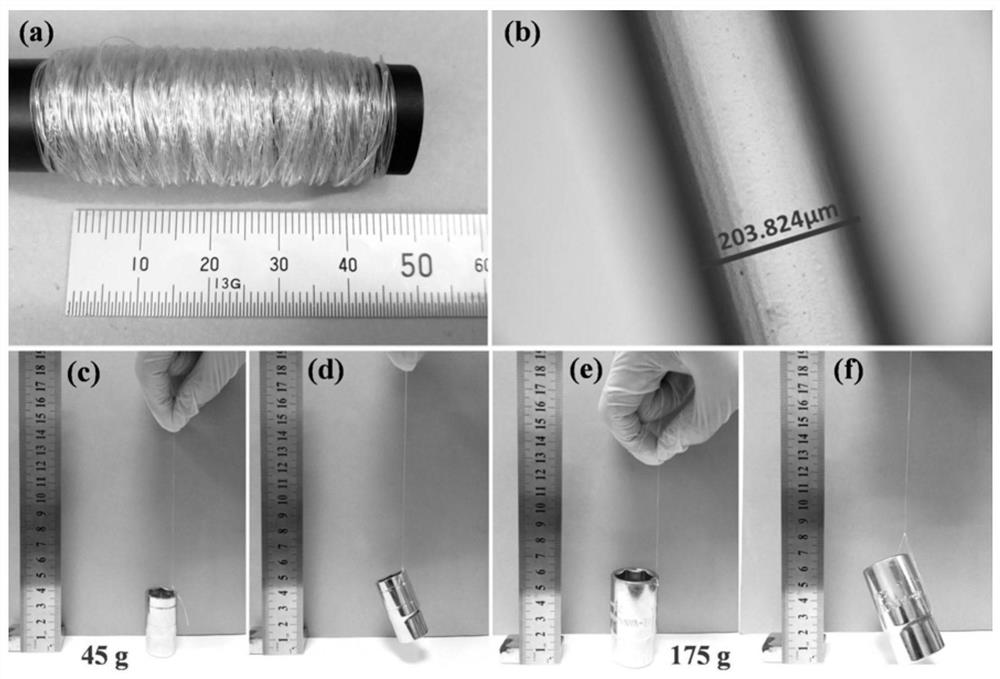

[0021] The physical picture of the prepared EVA fiber is as follows figure 1 Shown in (a), as can be seen from the figure, this invention can be continuously spun and the fiber diameter is uniform, figure 1 (b) is a polarizing microscope picture, from which it can be seen that the fiber diameter is 2...

Embodiment 2

[0028] (1) The quality of benzophenone, triallyl isocyanurate and EVA resin was mixed with 4g, 4g and 100g respectively and then extruded using a twin-screw extruder. The temperature of the heating zone of the extruder is set at 145, 145, 150, and 150°C, the rotation speed of the screw host is 45rpm, the rotation speed of the feeding rod is 35rpm, and the extrusion speed is 1.5m / min;

[0029] (2) The extruded melt is first drawn by the rollers installed in the ultraviolet light box, and its linear speed is about 9m / min. About 15m / min, the draft ratio is about 10;

[0030] (3) The power of the ultraviolet lamp installed in this ultraviolet light box is 1KW, and the length of the lamp tube is 40cm.

[0031] The EVA fiber obtained in this example was characterized by the same means as in Example 1, and the results showed that the two-way shape memory effect of the fiber was similar to that shown by the fiber obtained in Example 1.

Embodiment 3

[0033] (1) The quality of benzophenone, triallyl isocyanurate and EVA resin is mixed with 5g, 5g and 100g respectively and then extruded using a twin-screw extruder. The temperature of the heating zone of the extruder is set at 145, 145, 150, and 150°C, the rotation speed of the screw host is 50rpm, the rotation speed of the feeding rod is 40rpm, and the extrusion speed is 2m / min;

[0034] (2) The extruded melt is first drawn by the rollers installed in the ultraviolet light box, and its line speed is about 10m / min. About 20m / min, the draft ratio is about 10;

[0035] (3) The power of the ultraviolet lamp installed in this ultraviolet light box is 2KW, and the length of the lamp tube is 50cm.

[0036] The EVA fiber obtained in this example was characterized by the same means as in Example 1, and the results showed that the two-way shape memory effect of the fiber was similar to that shown by the fiber obtained in Example 1.

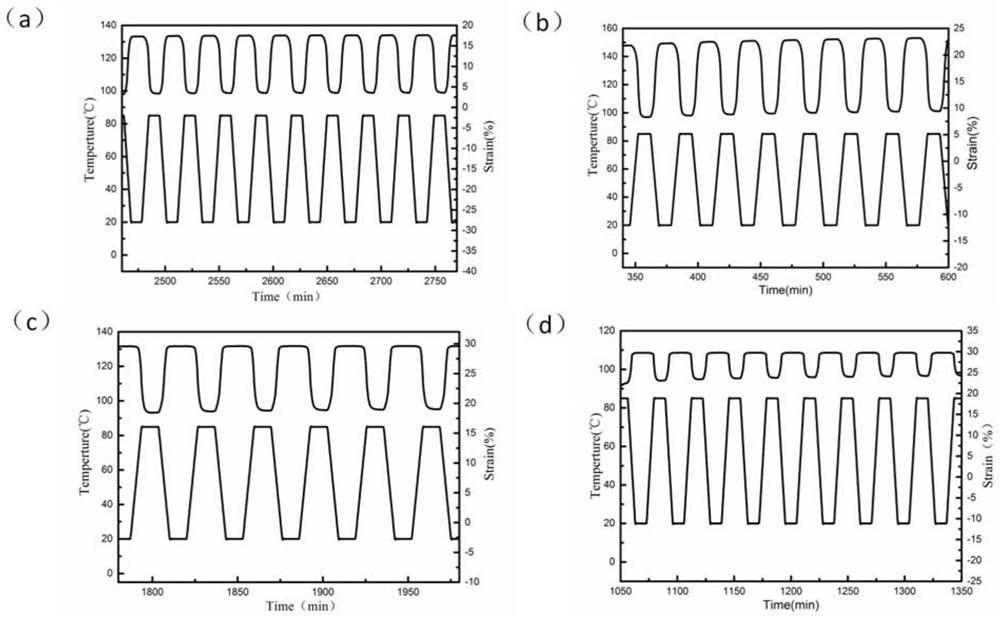

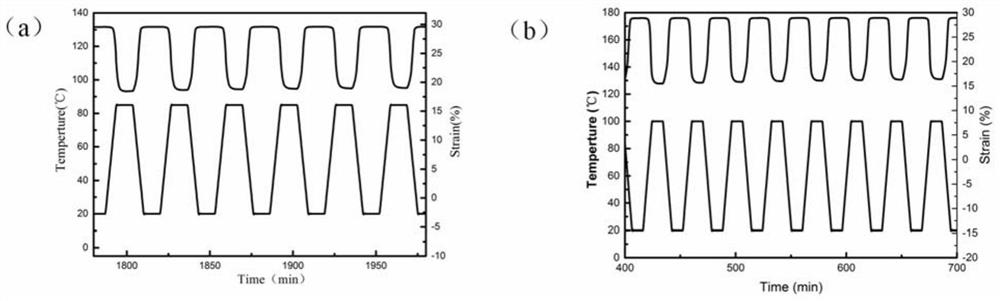

[0037] From the above three examples, it can be k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com